SERVICE AND ADJUSTMENTS

Unit cycles automatically when power is on. When doing Maintenance, you may be exposed to voltage sources, compressed air or moving parts. Personal injuries can occur. Before per-

forming any Maintenance or repair, unplug the compressor and bleed off all air pressure.

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST BE PERFORMED BY TRAINED SERVICE TECHNICIAN.

Before servicing:

●Unplug or disconnect electrical supply to the air compressor.

●Bleed tank of pressure.

●Allow the air compressor to cool.

To Replace or Clean Check Valve

1.Release all air pressure from air tank. See “To Drain Tank” in the Maintenance section.

2.Unplug outfit.

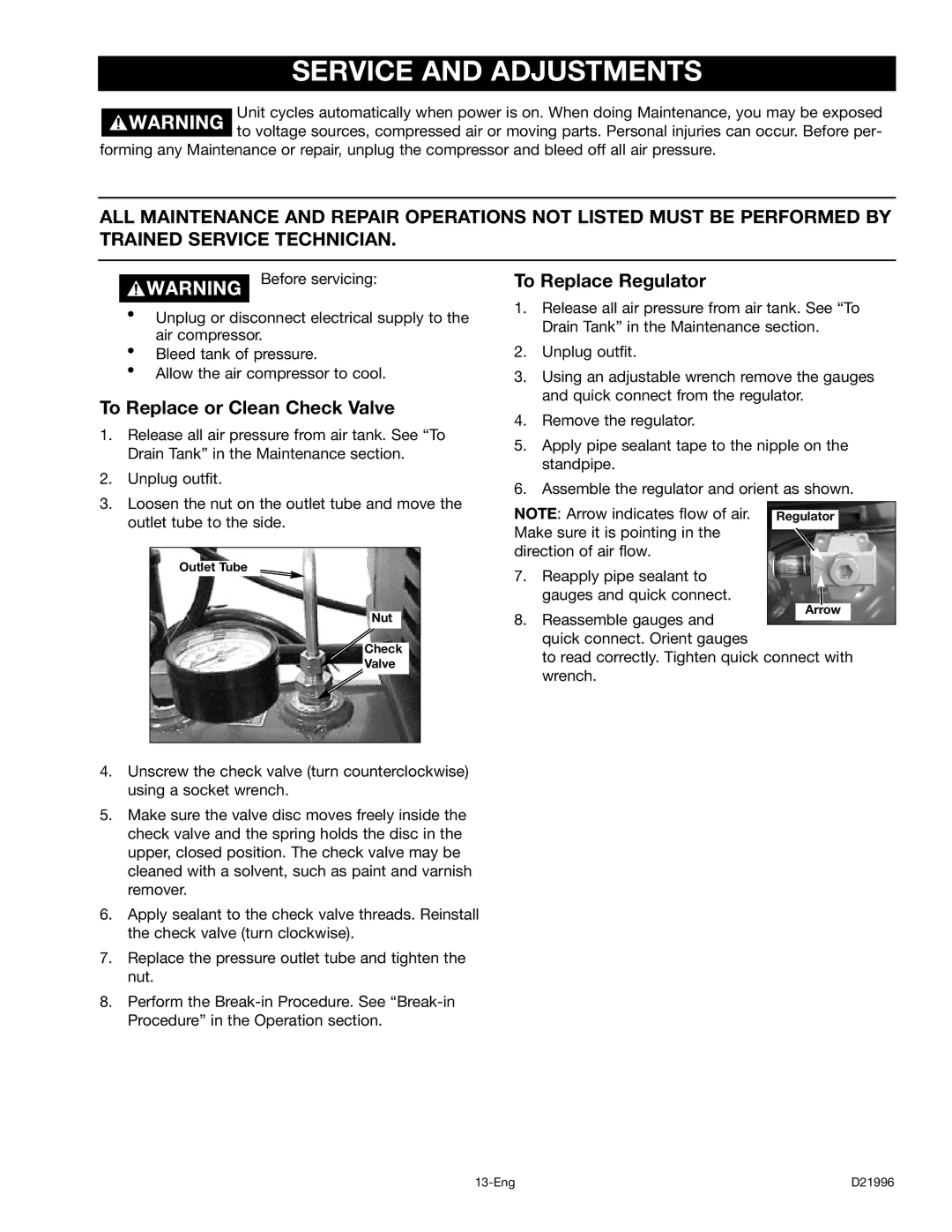

3.Loosen the nut on the outlet tube and move the outlet tube to the side.

To Replace Regulator

1.Release all air pressure from air tank. See “To Drain Tank” in the Maintenance section.

2.Unplug outfit.

3.Using an adjustable wrench remove the gauges and quick connect from the regulator.

4.Remove the regulator.

5.Apply pipe sealant tape to the nipple on the standpipe.

6.Assemble the regulator and orient as shown.

NOTE: Arrow indicates flow of air. |

|

Regulator | |

Make sure it is pointing in the |

|

| |

direction of air flow. |

|

Outlet Tube

Nut

7. Reapply pipe sealant to gauges and quick connect.

8. Reassemble gauges and quick connect. Orient gauges

Arrow

Check Valve

to read correctly. Tighten quick connect with wrench.

4.Unscrew the check valve (turn counterclockwise) using a socket wrench.

5.Make sure the valve disc moves freely inside the check valve and the spring holds the disc in the upper, closed position. The check valve may be cleaned with a solvent, such as paint and varnish remover.

6.Apply sealant to the check valve threads. Reinstall the check valve (turn clockwise).

7.Replace the pressure outlet tube and tighten the nut.

8.Perform the

D21996 |