SERVICE AND ADJUSTMENTS

Unit cycles automatically when

power is on. When doing Maintenance, you may be exposed to voltage sources, compressed air or moving parts. Personal injuries can occur. Before performing any Maintenance or repair, unplug the compressor and bleed off all air pressure.

ALL MAINTENANCE AND REPAIR OPERATIONS NOT LISTED MUST BE PERFORMED BY TRAINED SERVICE TECHNICIAN.

To Replace or Clean Check Valve

1.Release all air pressure from air tank. See “To Drain Tank” in the Maintenance section.

2.Unplug outfit.

3.Using a phillips screwdriver remove the air filter cover.

4.Remove the rear shrouds using

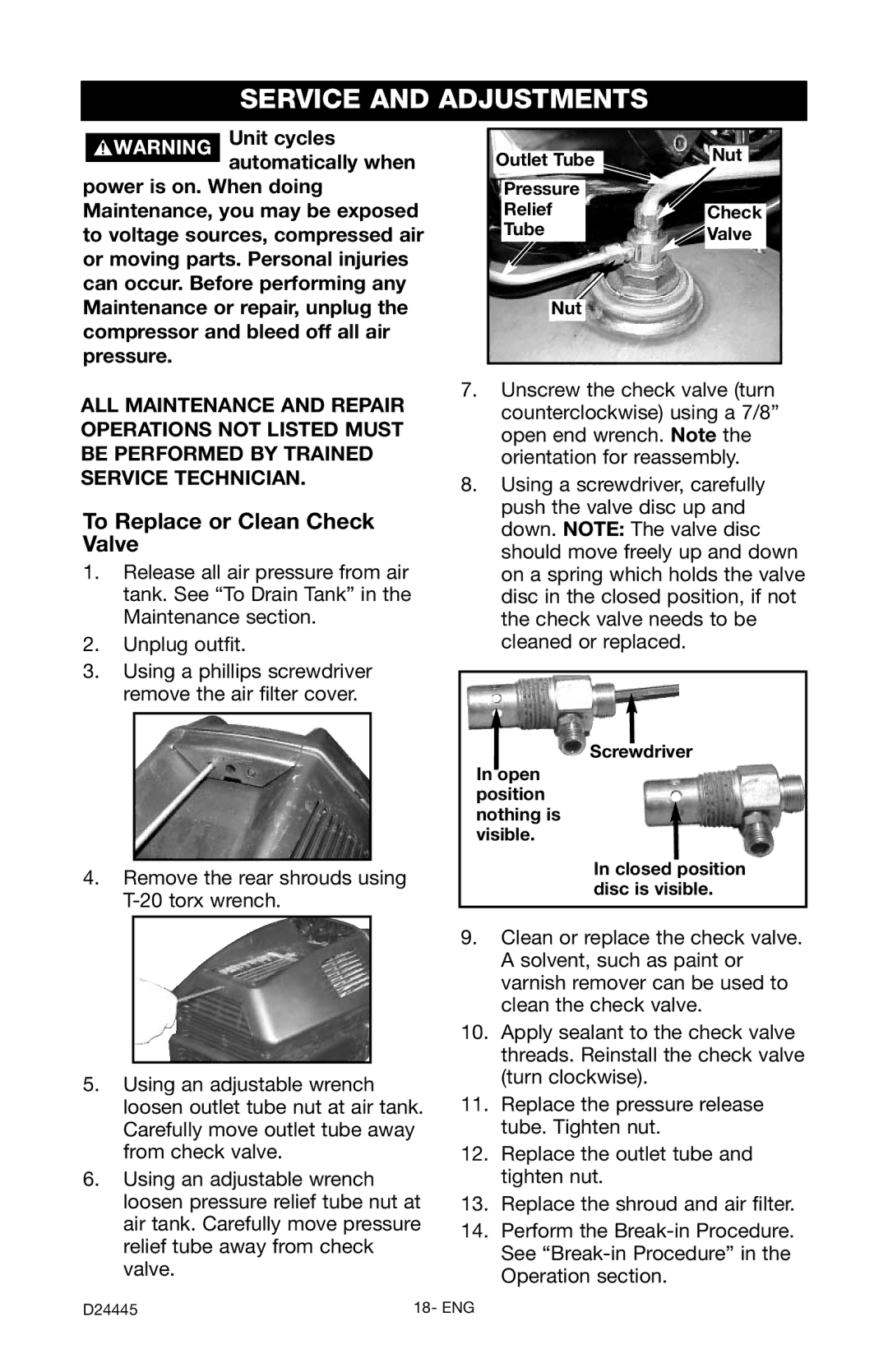

5.Using an adjustable wrench loosen outlet tube nut at air tank. Carefully move outlet tube away from check valve.

6.Using an adjustable wrench loosen pressure relief tube nut at air tank. Carefully move pressure relief tube away from check valve.

|

|

| Nut |

|

Outlet Tube | ||||

|

|

|

|

|

Pressure |

|

|

|

|

Relief |

|

|

|

|

| Check | |||

Tube |

| Valve | ||

Nut |

|

|

|

|

|

|

|

| |

7.Unscrew the check valve (turn counterclockwise) using a 7/8” open end wrench. Note the orientation for reassembly.

8.Using a screwdriver, carefully push the valve disc up and down. NOTE: The valve disc should move freely up and down on a spring which holds the valve disc in the closed position, if not the check valve needs to be cleaned or replaced.

Screwdriver

In open position nothing is visible.

In closed position disc is visible.

9.Clean or replace the check valve. A solvent, such as paint or varnish remover can be used to clean the check valve.

10.Apply sealant to the check valve threads. Reinstall the check valve (turn clockwise).

11.Replace the pressure release tube. Tighten nut.

12.Replace the outlet tube and tighten nut.

13.Replace the shroud and air filter.

14.Perform the

D24445 | 18- ENG |