USING THE HYDRAULIC LIFT LEVER

The hydraulic lift system provides power for raising and positioning three point hitch and belly mounted equipment. The system’s position control feature maintains the selected height or depth of the equipment. When the hydraulic lift lever is moved to a higher or lower setting, the system repositions the equipment and maintains that selected position.

•To raise an attachment using the hydraulic lift system, the engine must be running.

•Generally, an attachment can be lowered with the engine running or off.

•There is a direct relationship between the height of the equipment and the position of the lever in its slot. Operate the equipment to determine your preferred height setting and, consequently, the position of the lift lever in its slot.

•Move the lift lever forward in the slot to the position that lowers the equipment to the desired height setting. See Figure 18.

HYDRAULIC

LIFT LEVER

Lowest | Highest |

Height | |

Height | Position |

Position |

|

Figure 18

•Move the lift lever rearward in the slot to raise the equipment to a higher height setting, or all the way rearward to raise the equipment to the transport position. See Figure 18.

USING THE PTO SELECTION LEVER

WARNING: NEVER shift the PTO selec- tion lever while the PTO is engaged. Damage to internal components will occur.

The position of the PTO selection lever will deter- mine whether the rear PTO, mid PTO, or both PTO’s will be engaged when the PTO switch is acti- vated.

Pull the lever to the right side of the slot to clear the shift gate, then shift the lever as follows:

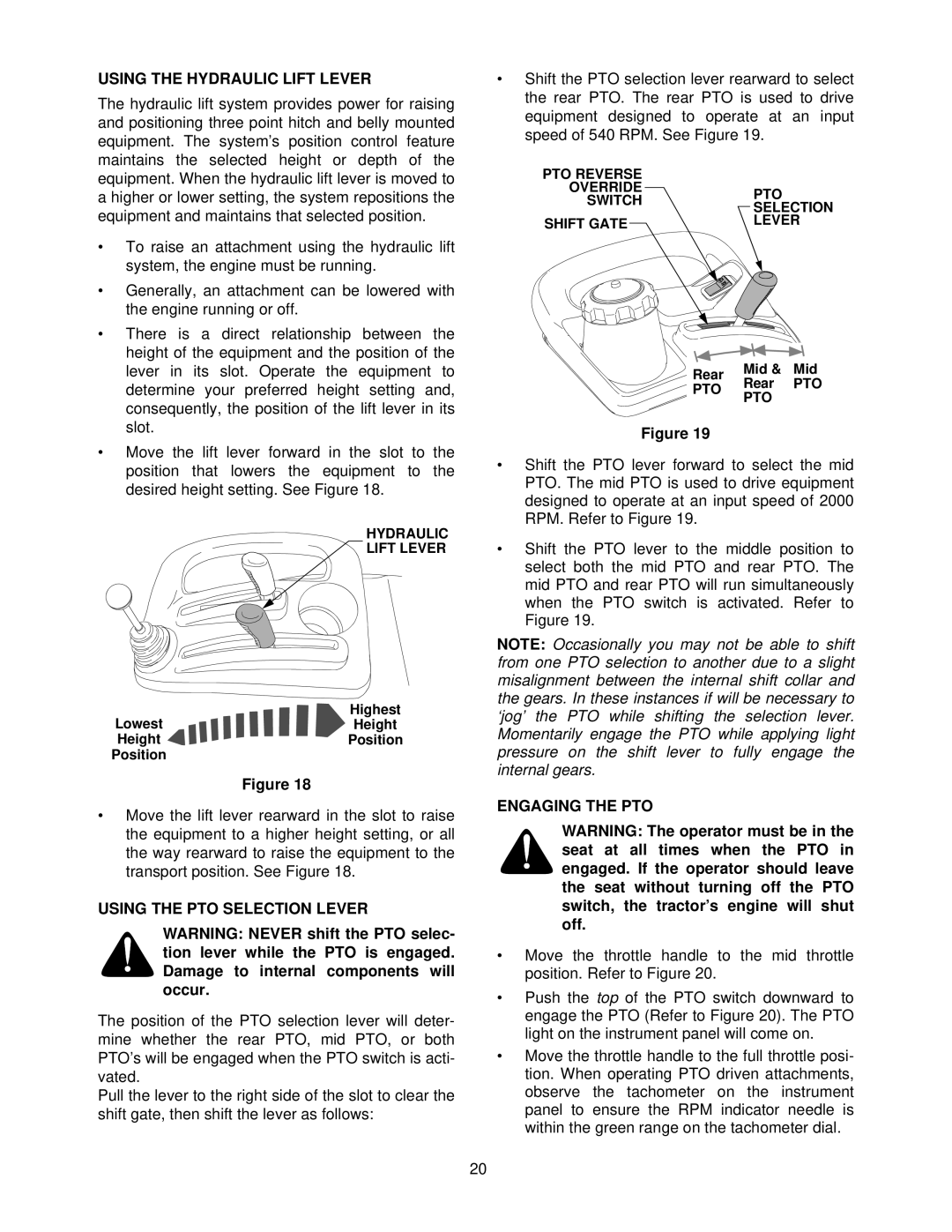

•Shift the PTO selection lever rearward to select the rear PTO. The rear PTO is used to drive equipment designed to operate at an input speed of 540 RPM. See Figure 19.

PTO REVERSE |

|

| ||||

OVERRIDE |

|

|

|

| PTO | |

|

|

| ||||

SWITCH |

| |||||

| SELECTION | |||||

|

|

|

|

|

| |

SHIFT GATE |

|

|

| LEVER | ||

|

| |||||

Rear | Mid & | Mid | |

Rear | PTO | ||

PTO | |||

PTO |

| ||

|

|

Figure 19

•Shift the PTO lever forward to select the mid PTO. The mid PTO is used to drive equipment designed to operate at an input speed of 2000 RPM. Refer to Figure 19.

•Shift the PTO lever to the middle position to select both the mid PTO and rear PTO. The mid PTO and rear PTO will run simultaneously when the PTO switch is activated. Refer to Figure 19.

NOTE: Occasionally you may not be able to shift from one PTO selection to another due to a slight misalignment between the internal shift collar and the gears. In these instances if will be necessary to ‘jog’ the PTO while shifting the selection lever. Momentarily engage the PTO while applying light pressure on the shift lever to fully engage the internal gears.

ENGAGING THE PTO

WARNING: The operator must be in the seat at all times when the PTO in engaged. If the operator should leave the seat without turning off the PTO switch, the tractor’s engine will shut off.

•Move the throttle handle to the mid throttle position. Refer to Figure 20.

•Push the top of the PTO switch downward to engage the PTO (Refer to Figure 20). The PTO light on the instrument panel will come on.

•Move the throttle handle to the full throttle posi- tion. When operating PTO driven attachments, observe the tachometer on the instrument panel to ensure the RPM indicator needle is within the green range on the tachometer dial.

20