•Reconnect the upper shift rod to the lower shift rod by reinserting the hairpin clip removed earlier and sliding the shift rod connector back down into place.

IMPORTANT: Make certain to check for correct adjustment of the shift rod as instructed under Final Adjustments in the Assembly Section, before operating the snow thrower.

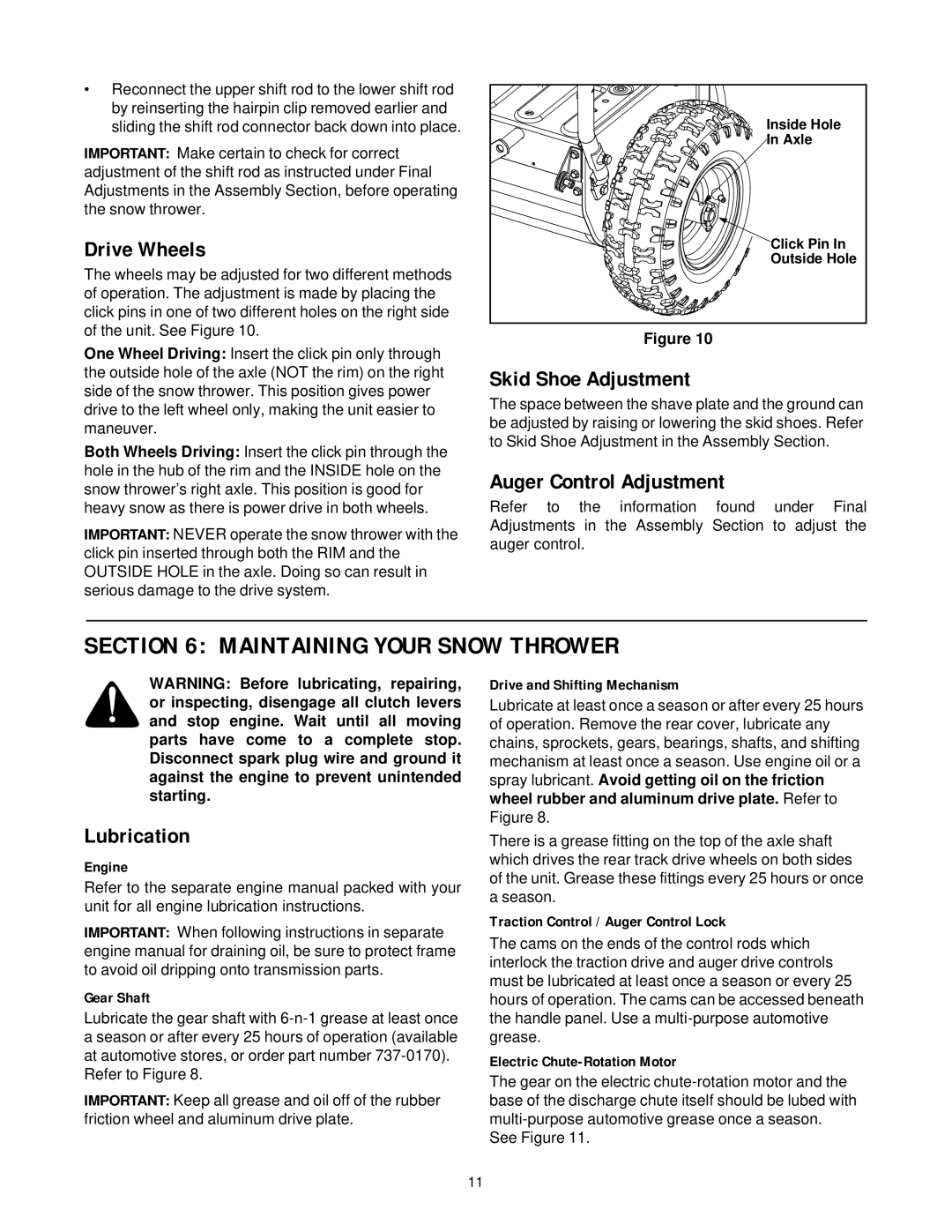

Drive Wheels

The wheels may be adjusted for two different methods of operation. The adjustment is made by placing the click pins in one of two different holes on the right side of the unit. See Figure 10.

One Wheel Driving: Insert the click pin only through the outside hole of the axle (NOT the rim) on the right side of the snow thrower. This position gives power drive to the left wheel only, making the unit easier to maneuver.

Both Wheels Driving: Insert the click pin through the hole in the hub of the rim and the INSIDE hole on the snow thrower’s right axle. This position is good for heavy snow as there is power drive in both wheels.

IMPORTANT: NEVER operate the snow thrower with the click pin inserted through both the RIM and the OUTSIDE HOLE in the axle. Doing so can result in serious damage to the drive system.

Inside Hole |

In Axle |

Click Pin In |

Outside Hole |

Figure 10

Skid Shoe Adjustment

The space between the shave plate and the ground can be adjusted by raising or lowering the skid shoes. Refer to Skid Shoe Adjustment in the Assembly Section.

Auger Control Adjustment

Refer to the information found under Final Adjustments in the Assembly Section to adjust the auger control.

SECTION 6: MAINTAINING YOUR SNOW THROWER

WARNING: Before lubricating, repairing, or inspecting, disengage all clutch levers and stop engine. Wait until all moving parts have come to a complete stop. Disconnect spark plug wire and ground it against the engine to prevent unintended starting.

Lubrication

Engine

Refer to the separate engine manual packed with your unit for all engine lubrication instructions.

IMPORTANT: When following instructions in separate engine manual for draining oil, be sure to protect frame to avoid oil dripping onto transmission parts.

Gear Shaft

Lubricate the gear shaft with

Refer to Figure 8.

IMPORTANT: Keep all grease and oil off of the rubber friction wheel and aluminum drive plate.

Drive and Shifting Mechanism

Lubricate at least once a season or after every 25 hours of operation. Remove the rear cover, lubricate any chains, sprockets, gears, bearings, shafts, and shifting mechanism at least once a season. Use engine oil or a spray lubricant. Avoid getting oil on the friction wheel rubber and aluminum drive plate. Refer to Figure 8.

There is a grease fitting on the top of the axle shaft which drives the rear track drive wheels on both sides of the unit. Grease these fittings every 25 hours or once a season.

Traction Control / Auger Control Lock

The cams on the ends of the control rods which interlock the traction drive and auger drive controls must be lubricated at least once a season or every 25 hours of operation. The cams can be accessed beneath the handle panel. Use a

Electric Chute-Rotation Motor

The gear on the electric

11