ASSEMBLY

ASSEMBLING TOOL RESTS

1.Assemble the

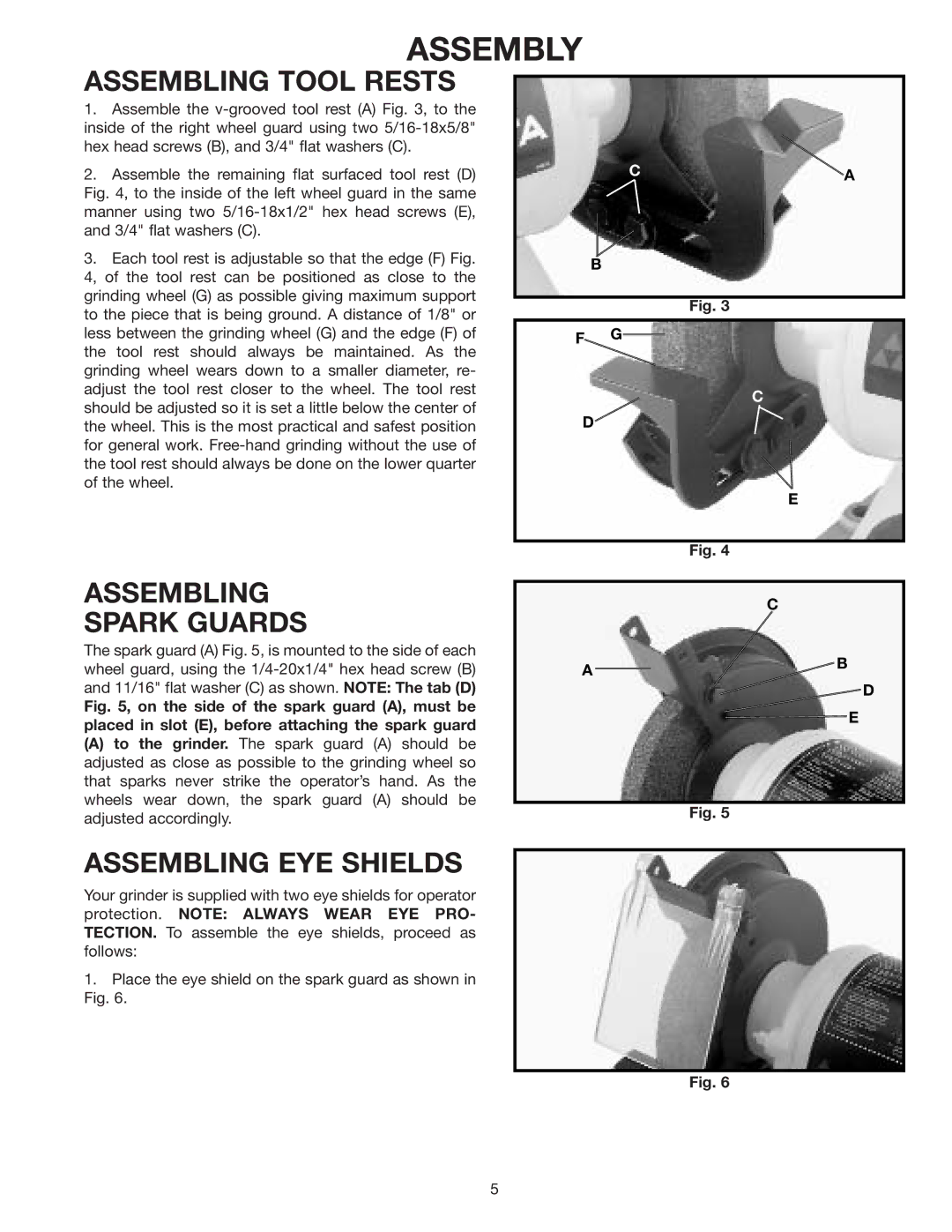

2.Assemble the remaining flat surfaced tool rest (D) Fig. 4, to the inside of the left wheel guard in the same manner using two

3.Each tool rest is adjustable so that the edge (F) Fig. 4, of the tool rest can be positioned as close to the grinding wheel (G) as possible giving maximum support to the piece that is being ground. A distance of 1/8" or less between the grinding wheel (G) and the edge (F) of the tool rest should always be maintained. As the grinding wheel wears down to a smaller diameter, re- adjust the tool rest closer to the wheel. The tool rest should be adjusted so it is set a little below the center of the wheel. This is the most practical and safest position for general work.

ASSEMBLING

SPARK GUARDS

The spark guard (A) Fig. 5, is mounted to the side of each wheel guard, using the

Fig. 5, on the side of the spark guard (A), must be placed in slot (E), before attaching the spark guard

(A)to the grinder. The spark guard (A) should be adjusted as close as possible to the grinding wheel so that sparks never strike the operator’s hand. As the wheels wear down, the spark guard (A) should be adjusted accordingly.

C![]() A

A

B

Fig. 3

F G

C

D

|

| E |

|

|

|

|

| Fig. 4 |

|

|

|

|

| C |

A |

| B |

|

|

D

E

Fig. 5

ASSEMBLING EYE SHIELDS

Your grinder is supplied with two eye shields for operator protection. NOTE: ALWAYS WEAR EYE PRO- TECTION. To assemble the eye shields, proceed as follows:

1.Place the eye shield on the spark guard as shown in Fig. 6.

Fig. 6

5