MAINTENANCE

CHANGING

ABRASIVE DISCS

MAKE CERTAIN MACHINE IS DISCONNECTED FROM POWER SOURCE.

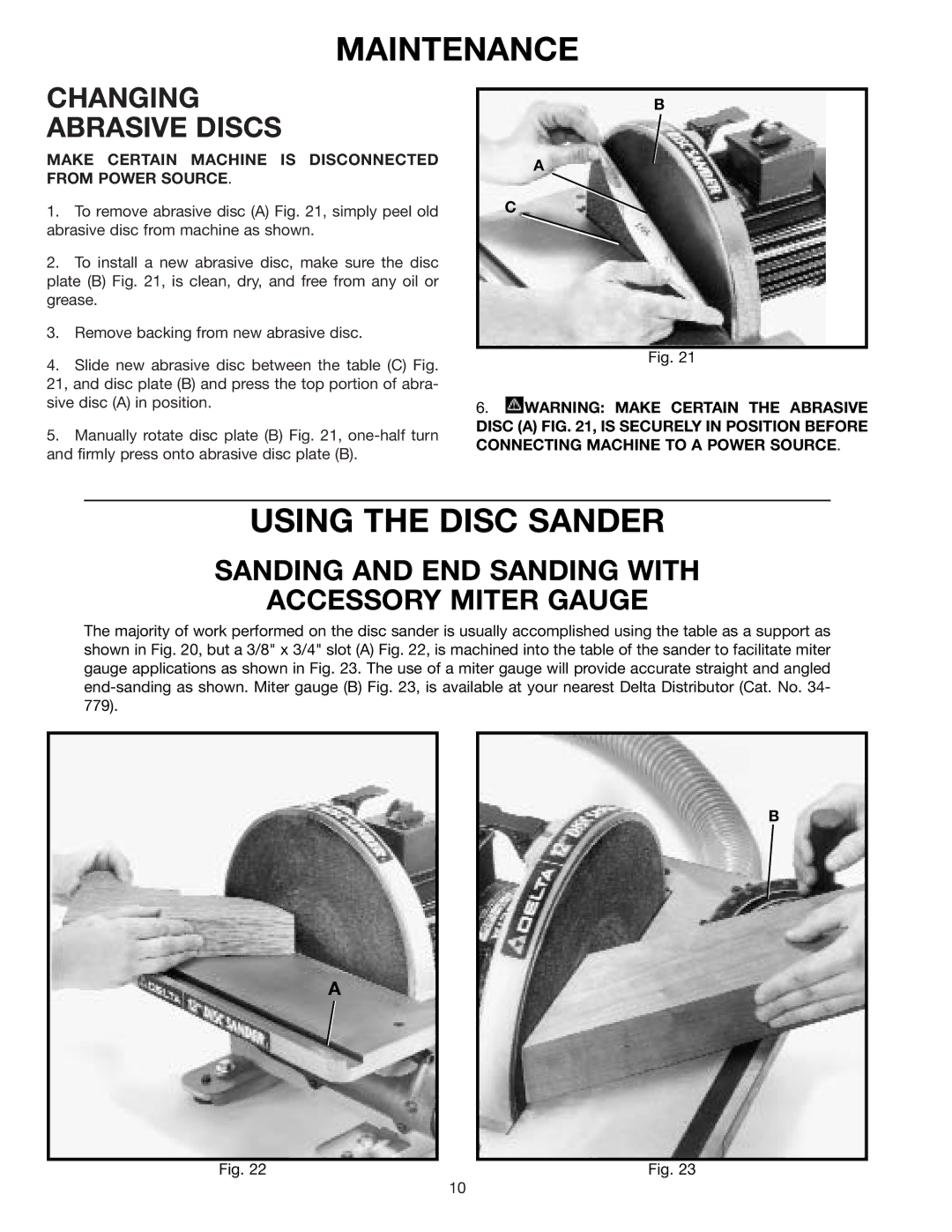

1.To remove abrasive disc (A) Fig. 21, simply peel old abrasive disc from machine as shown.

2.To install a new abrasive disc, make sure the disc plate (B) Fig. 21, is clean, dry, and free from any oil or grease.

3.Remove backing from new abrasive disc.

4.Slide new abrasive disc between the table (C) Fig. 21, and disc plate (B) and press the top portion of abra- sive disc (A) in position.

5.Manually rotate disc plate (B) Fig. 21,

B

A

C

Fig. 21

6.![]() WARNING: MAKE CERTAIN THE ABRASIVE DISC (A) FIG. 21, IS SECURELY IN POSITION BEFORE CONNECTING MACHINE TO A POWER SOURCE.

WARNING: MAKE CERTAIN THE ABRASIVE DISC (A) FIG. 21, IS SECURELY IN POSITION BEFORE CONNECTING MACHINE TO A POWER SOURCE.

USING THE DISC SANDER

SANDING AND END SANDING WITH

ACCESSORY MITER GAUGE

The majority of work performed on the disc sander is usually accomplished using the table as a support as shown in Fig. 20, but a 3/8" x 3/4" slot (A) Fig. 22, is machined into the table of the sander to facilitate miter gauge applications as shown in Fig. 23. The use of a miter gauge will provide accurate straight and angled

B

A

Fig. 22 | Fig. 23 |

10