ASSEMBLY

ATTACHING LATHE BED

TO PEDESTALS

1.Remove tailstock, headstock, and tool rest from the lathe bed. NOTE: See “ADJUSTING HEADSTOCK AND TAILSTOCK” and “TOOL REST” for removal/installation instructions.

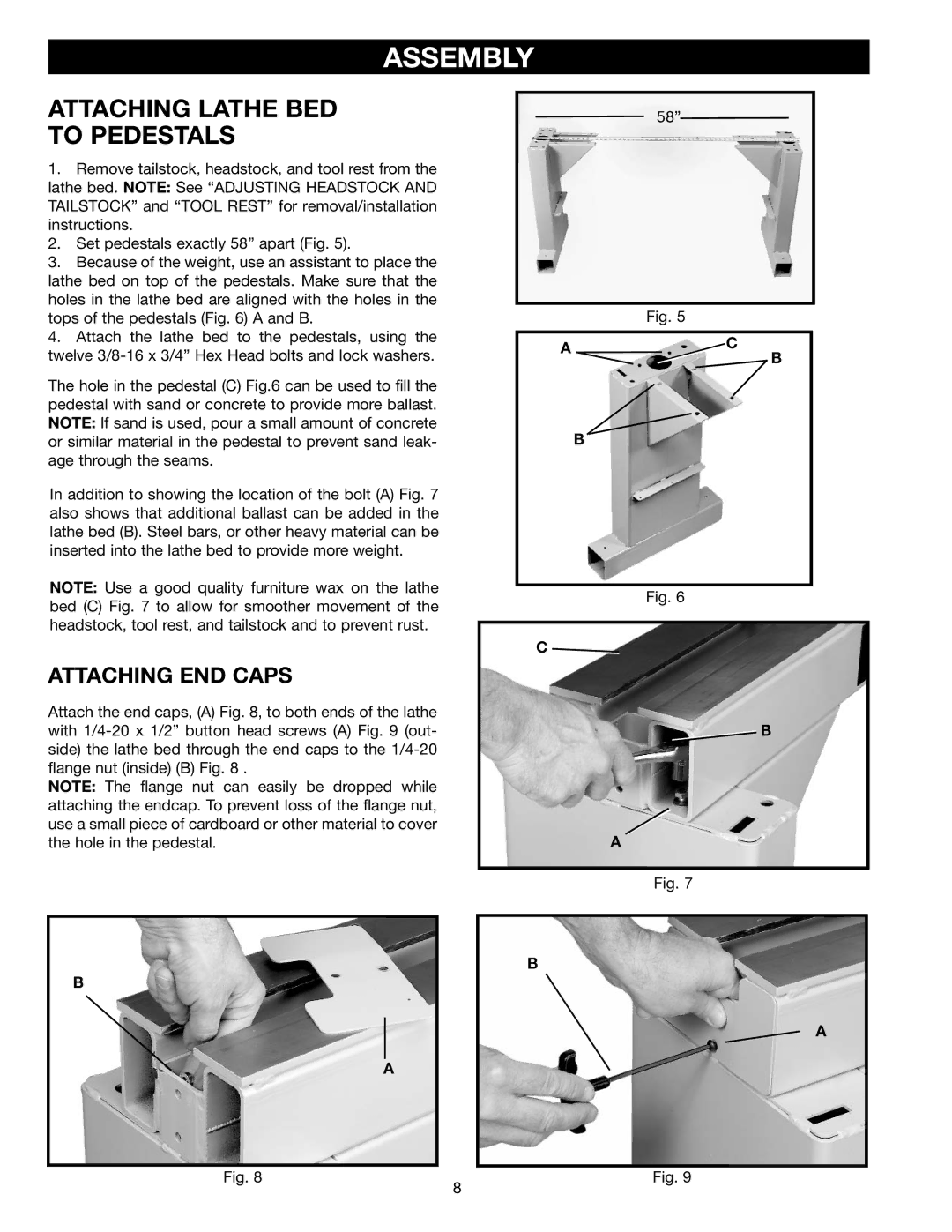

2.Set pedestals exactly 58” apart (Fig. 5).

3.Because of the weight, use an assistant to place the lathe bed on top of the pedestals. Make sure that the holes in the lathe bed are aligned with the holes in the tops of the pedestals (Fig. 6) A and B.

4.Attach the lathe bed to the pedestals, using the twelve

The hole in the pedestal (C) Fig.6 can be used to fill the pedestal with sand or concrete to provide more ballast. NOTE: If sand is used, pour a small amount of concrete or similar material in the pedestal to prevent sand leak- age through the seams.

In addition to showing the location of the bolt (A) Fig. 7 also shows that additional ballast can be added in the lathe bed (B). Steel bars, or other heavy material can be inserted into the lathe bed to provide more weight.

NOTE: Use a good quality furniture wax on the lathe bed (C) Fig. 7 to allow for smoother movement of the headstock, tool rest, and tailstock and to prevent rust.

ATTACHING END CAPS

58”

Fig. 5

AC

B

Fig. 6

C ![]()

B

Attach the end caps, (A) Fig. 8, to both ends of the lathe with

NOTE: The flange nut can easily be dropped while attaching the endcap. To prevent loss of the flange nut, use a small piece of cardboard or other material to cover the hole in the pedestal.

B

A

![]() B

B

A

Fig. 7

B

A

Fig. 8 | Fig. 9 |

| 8 |