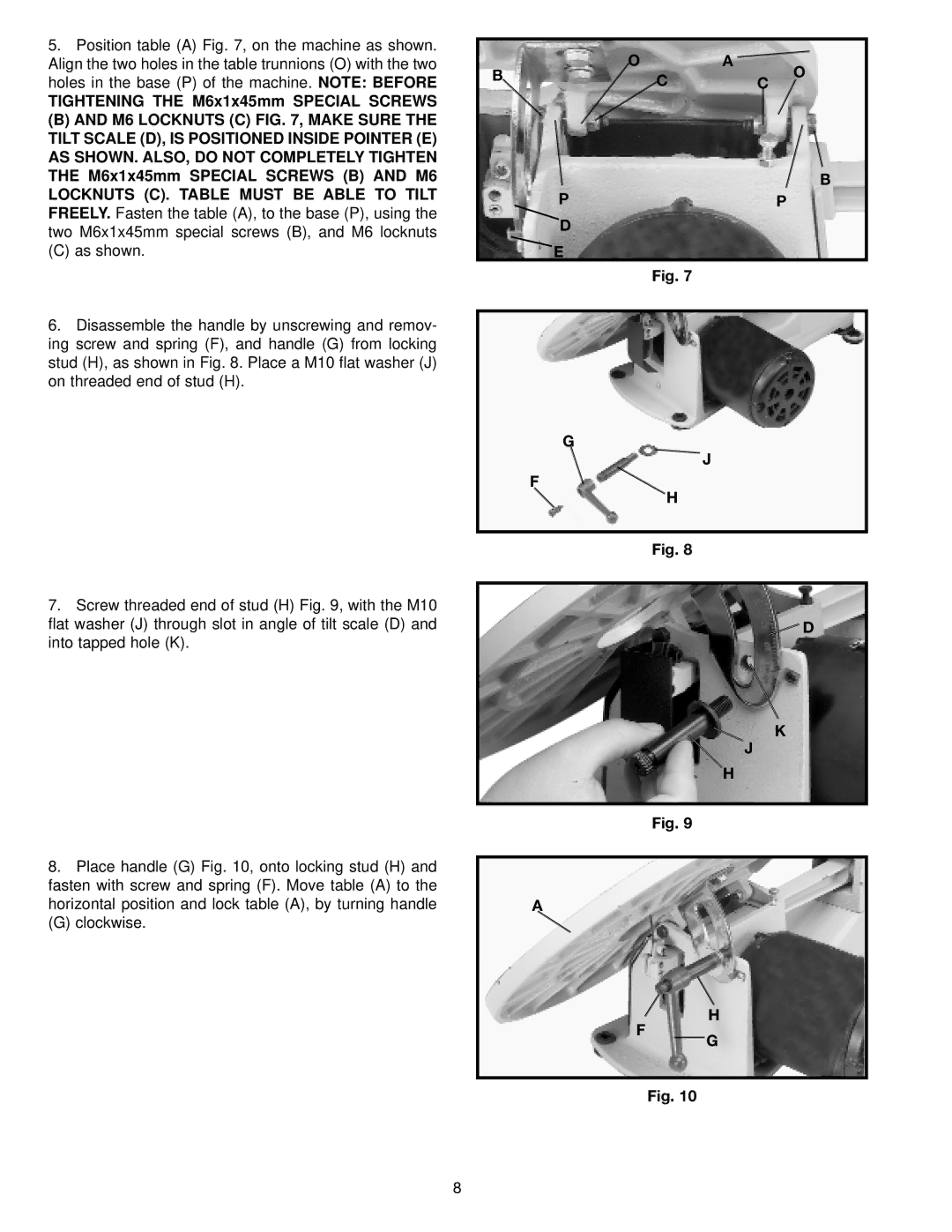

5.Position table (A) Fig. 7, on the machine as shown. Align the two holes in the table trunnions (O) with the two holes in the base (P) of the machine. NOTE: BEFORE

TIGHTENING THE M6x1x45mm SPECIAL SCREWS

(B) AND M6 LOCKNUTS (C) FIG. 7, MAKE SURE THE TILT SCALE (D), IS POSITIONED INSIDE POINTER (E) AS SHOWN. ALSO, DO NOT COMPLETELY TIGHTEN THE M6x1x45mm SPECIAL SCREWS (B) AND M6 LOCKNUTS (C). TABLE MUST BE ABLE TO TILT FREELY. Fasten the table (A), to the base (P), using the two M6x1x45mm special screws (B), and M6 locknuts

(C) as shown.

6.Disassemble the handle by unscrewing and remov- ing screw and spring (F), and handle (G) from locking stud (H), as shown in Fig. 8. Place a M10 flat washer (J) on threaded end of stud (H).

7.Screw threaded end of stud (H) Fig. 9, with the M10 flat washer (J) through slot in angle of tilt scale (D) and into tapped hole (K).

OA ![]()

BCC O

B

P | P |

D |

|

E |

|

| Fig. 7 |

G

J

F

H

Fig. 8

![]() D

D

K

J

H

Fig. 9

8.Place handle (G) Fig. 10, onto locking stud (H) and fasten with screw and spring (F). Move table (A) to the horizontal position and lock table (A), by turning handle

(G) clockwise.

A

F

H

G

Fig. 10

8