CONSTRUCTING A FEATHERBOARD

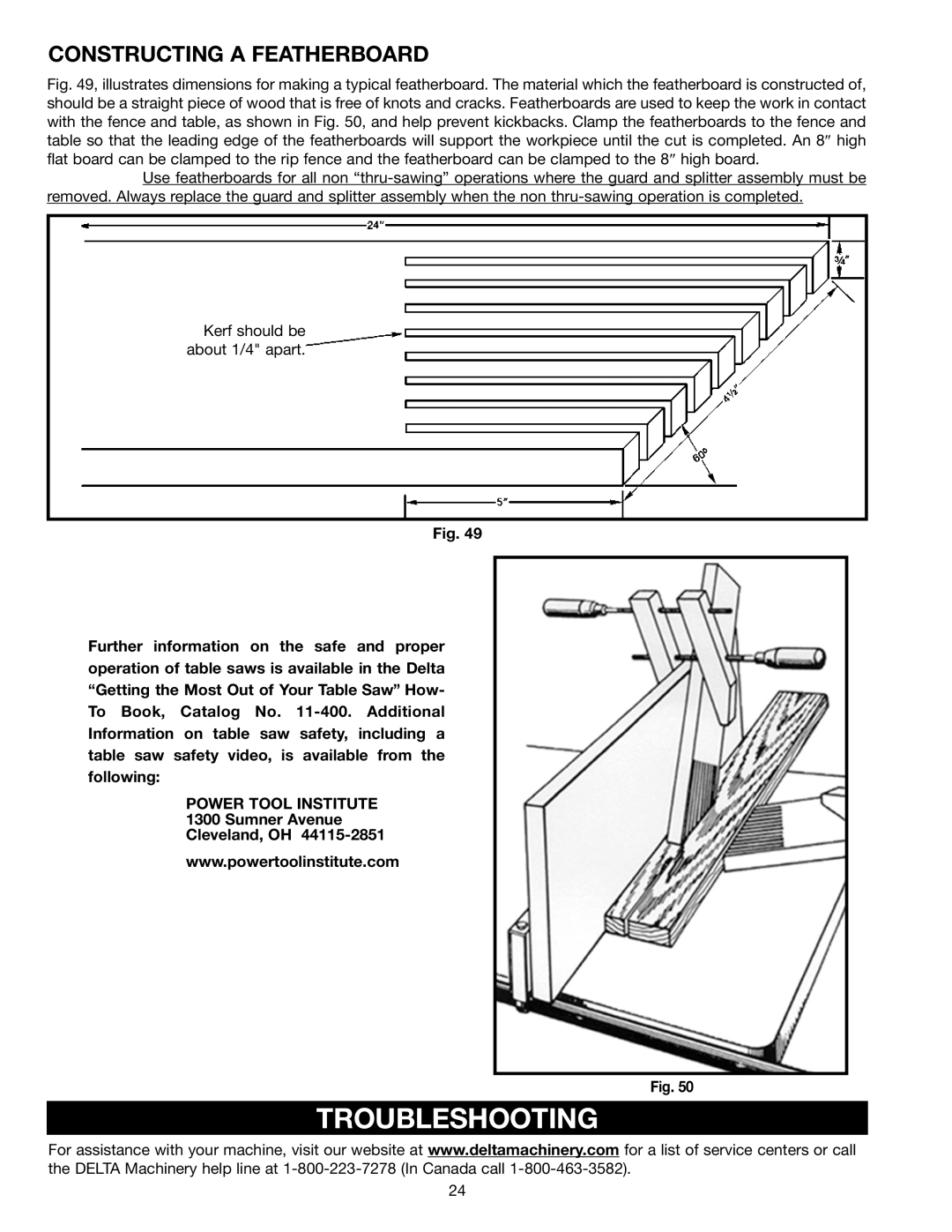

Fig. 49, illustrates dimensions for making a typical featherboard. The material which the featherboard is constructed of, should be a straight piece of wood that is free of knots and cracks. Featherboards are used to keep the work in contact with the fence and table, as shown in Fig. 50, and help prevent kickbacks. Clamp the featherboards to the fence and table so that the leading edge of the featherboards will support the workpiece until the cut is completed. An 8″ high flat board can be clamped to the rip fence and the featherboard can be clamped to the 8″ high board.

Use featherboards for all non

Use featherboards for all non “thru-sawing” operations where the guard and splitter assembly must be removed. Always replace the guard and splitter assembly when the non thru-sawing operation is completed.

Kerf should be about 1/4" apart.

Fig. 49

Further information on the safe and proper operation of table saws is available in the Delta “Getting the Most Out of Your Table Saw” How- To Book, Catalog No.

POWER TOOL INSTITUTE

1300 Sumner Avenue

Cleveland, OH

www.powertoolinstitute.com

Fig. 50

TROUBLESHOOTING

For assistance with your machine, visit our website at www.deltamachinery.com for a list of service centers or call the DELTA Machinery help line at

24