TEST CONFIGURATIONS

| TO OSCILLOSCOPE | |

| L | VI(+) |

|

| |

BATTERY | 2 | 100uF |

| Tantalum | |

|

| |

Note: Input

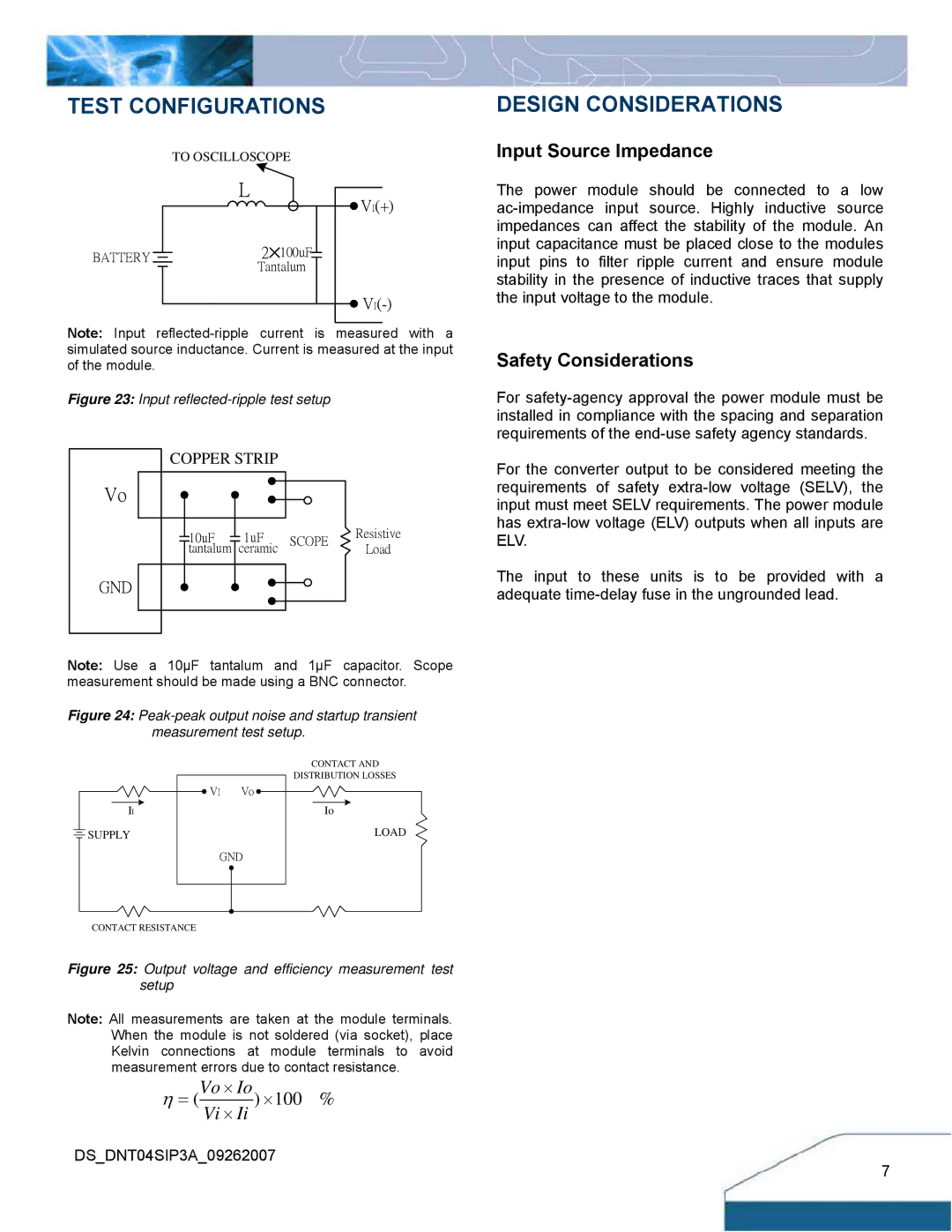

Figure 23: Input reflected-ripple test setup

COPPER STRIP

Vo

| 10uF |

| 1uF | SCOPE | Resistive |

|

|

| |||

tantalum | ceramic | Load | |||

GND

Note: Use a 10µF tantalum and 1µF capacitor. Scope measurement should be made using a BNC connector.

Figure 24: Peak-peak output noise and startup transient measurement test setup.

|

|

|

|

|

| CONTACT AND | ||

|

|

|

|

|

| DISTRIBUTION LOSSES | ||

|

|

| VI | Vo |

| |||

|

|

|

|

|

|

| ||

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

| |

| II |

|

|

|

|

| Io |

|

SUPPLY |

|

|

|

|

| LOAD | ||

|

|

| GND |

|

|

| ||

|

|

|

|

|

|

|

|

|

CONTACT RESISTANCE

Figure 25: Output voltage and efficiency measurement test setup

Note: All measurements are taken at the module terminals. When the module is not soldered (via socket), place Kelvin connections at module terminals to avoid measurement errors due to contact resistance.

η = (Vo × Io) ×100 %

Vi × Ii

DS_DNT04SIP3A_09262007

DESIGN CONSIDERATIONS

Input Source Impedance

The power module should be connected to a low

Safety Considerations

For

For the converter output to be considered meeting the requirements of safety

The input to these units is to be provided with a adequate

7