DVP01PU-H specifications

Delta Electronics, a leader in power and thermal management solutions, has introduced the DVP01PU-H, an innovative product designed to enhance power supply efficiency and reliability. This device serves as a crucial component in various industrial and commercial applications, providing seamless integration and robust performance.One of the main features of the DVP01PU-H is its compact design, which allows for easy installation in space-constrained environments. Despite its small footprint, the device boasts a high power density, making it ideal for applications where efficiency is paramount. The DVP01PU-H offers a substantial output power rating, making it suitable for powering a wide range of equipment and devices.

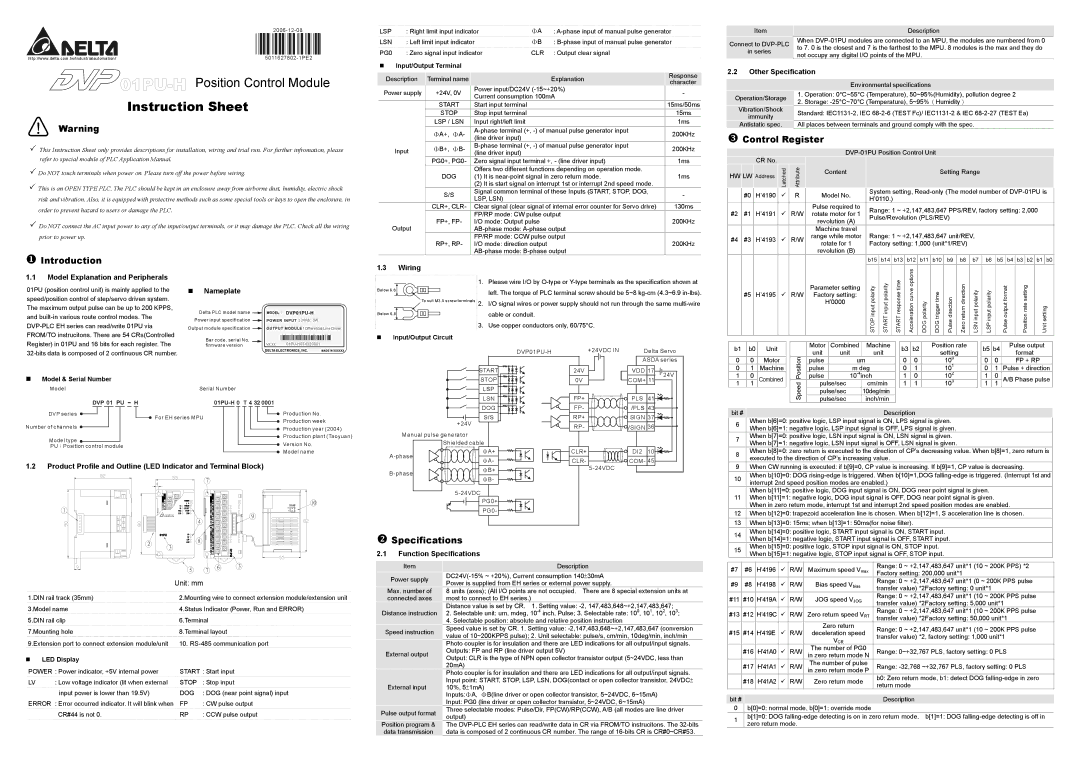

The Delta DVP01PU-H is equipped with advanced power management technologies, including digital control and precise voltage regulation. These features ensure that the output remains stable and reliable, even under varying load conditions. The device also incorporates built-in protections against overcurrent, short circuits, and overheating, which enhances its durability and safety in challenging operating environments.

Another standout characteristic of the DVP01PU-H is its compatibility with various input voltages, making it a versatile solution for global deployment. This flexibility allows users to utilize the device in different regions without the need for additional modifications, simplifying the installation process and reducing operational costs.

The DVP01PU-H includes smart communication capabilities, employing protocols that facilitate seamless integration with existing systems and infrastructure. This feature is particularly beneficial for users seeking to implement Industry 4.0 solutions, as it allows for real-time monitoring and control of power supply systems.

In summary, Delta Electronics' DVP01PU-H is an advanced power supply solution that combines compact design, high power density, and robust protection mechanisms. With its adaptability to various operating conditions and environments, as well as its integration with modern communication technologies, the DVP01PU-H stands out as an exceptional choice for businesses looking to improve their power management systems. This device not only enhances operational efficiency but also supports the transition towards more intelligent and connected industrial ecosystems.