EME-A22A specifications

Delta Electronics has long been a leader in power and thermal management solutions, and the EME-A22A model exemplifies the company's commitment to innovation and excellence in these areas. This advanced power supply unit is designed for industrial applications that require high efficiency and reliability.One of the main features of the EME-A22A is its high efficiency rating, which is typically over 90%. This efficiency not only helps in reducing energy consumption but also minimizes heat generation, contributing to a more environmentally friendly solution. With its compact design, the EME-A22A is suitable for integration into a wide range of equipment, from industrial machines to automation systems.

The EME-A22A supports a wide input voltage range, allowing it to adapt to various operating environments and maintaining stable performance even in challenging conditions. Its robust design ensures durability, making it ideal for demanding industrial settings. The unit is also equipped with functionalities such as over-voltage protection, over-current protection, and short circuit protection, ensuring the safety of connected devices and enhancing overall system reliability.

Delta Electronics has integrated several cutting-edge technologies into the EME-A22A. For example, the unit employs advanced switching techniques that contribute to its high efficiency and low thermal output. The incorporation of intelligent control mechanisms also allows the power supply to adjust its output based on real-time demand, further optimizing energy use.

Another characteristic that stands out is the EME-A22A’s compliance with international safety and environmental standards. This makes it a suitable choice for manufacturers looking to meet regulatory requirements while also seeking sustainability in their operations.

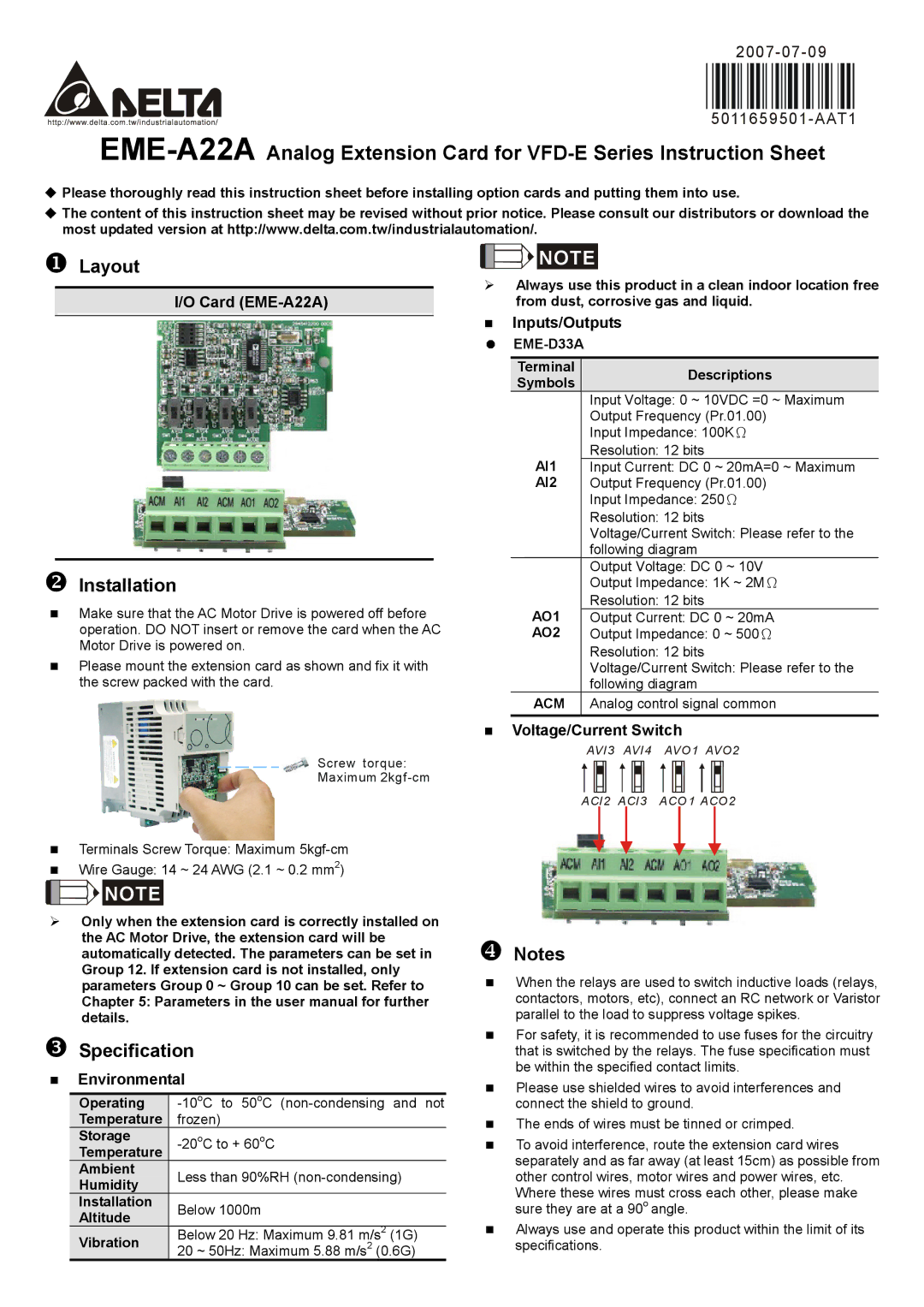

The design of the EME-A22A emphasizes ease of installation and maintenance, featuring user-friendly connectors and clear indicators for monitoring system status. Additionally, Delta Electronics provides comprehensive technical support and documentation, ensuring that customers have all the resources needed for effective integration and long-term operation.

Overall, the Delta Electronics EME-A22A is a powerful, efficient, and reliable power supply unit that meets the demanding needs of modern industrial applications. Its advanced technologies and robust design make it a suitable choice for businesses that prioritize performance, safety, and sustainability.