OWNER’S MANUAL

INSTALLATION

Continued

4.If installing bottom mounting screw into hollow or solid wall, install wall anchor. Follow steps 1 through 4 under Attach- ing To Wall Anchor Method, page 8. If installing bottom mounting screw into wall stud, drill holes at marked loca- tions using 9/64" drill bit.

5.Replace heater onto mounting bracket.

6.Place spacer between bottom mount- ing hole and wall anchor or drilled hole.

7.Hold spacer in place with one hand. With other hand, insert mounting screw through bottom mounting hole and spacer. Place tip of screw in opening of wall anchor or drilled hole.

8.Tighten screw until heater is firmly secured to wall. Do not over tighten. Note: Do not replace front panel at this time. Replace front panel after making gas connections and checking for leaks. (see page 10).

![]() CAUTION: Use only new, black iron or steel pipe. Inter-

CAUTION: Use only new, black iron or steel pipe. Inter-

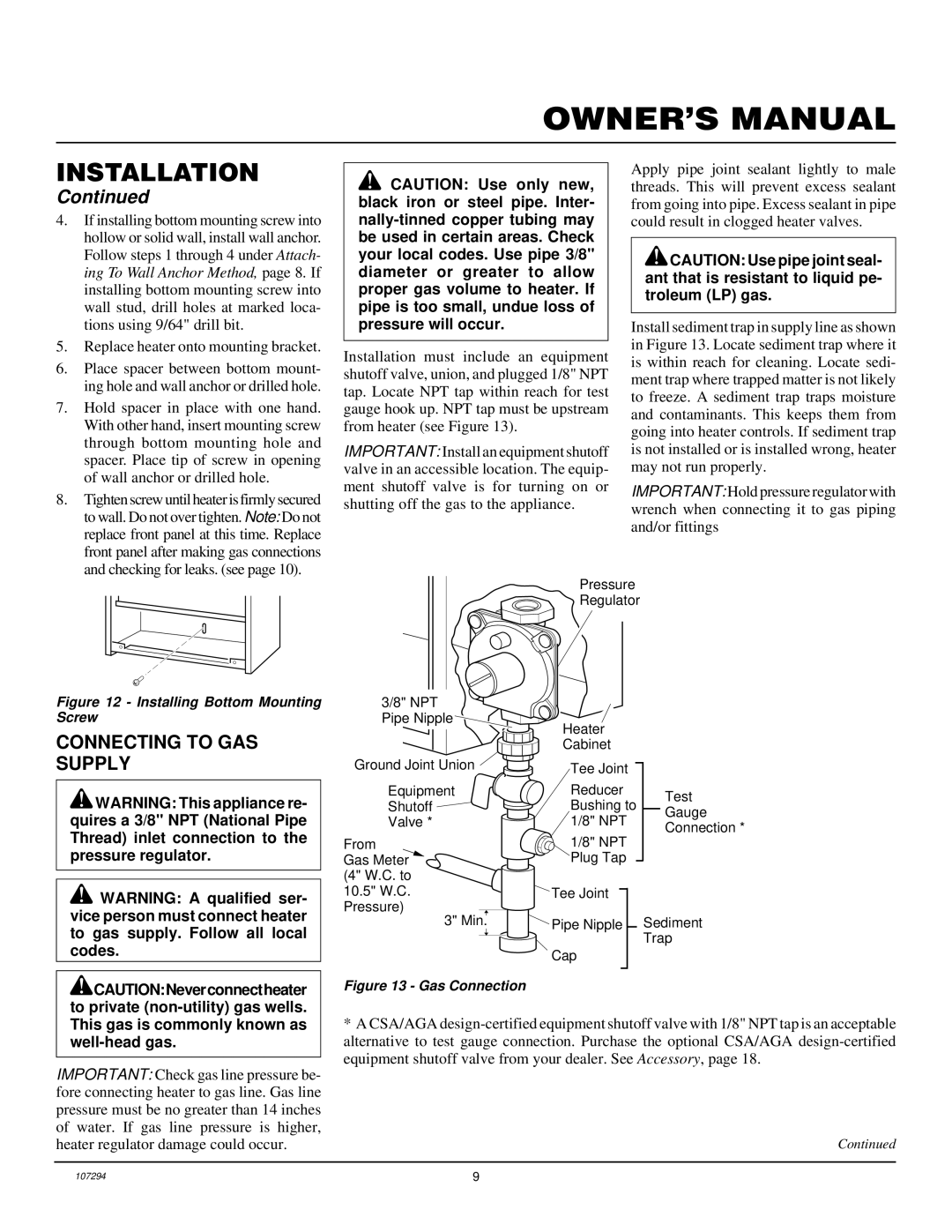

Installation must include an equipment shutoff valve, union, and plugged 1/8" NPT tap. Locate NPT tap within reach for test gauge hook up. NPT tap must be upstream from heater (see Figure 13).

IMPORTANT: Install an equipment shutoff valve in an accessible location. The equip- ment shutoff valve is for turning on or shutting off the gas to the appliance.

Apply pipe joint sealant lightly to male threads. This will prevent excess sealant from going into pipe. Excess sealant in pipe could result in clogged heater valves.

![]() CAUTION: Use pipe joint seal- ant that is resistant to liquid pe- troleum (LP) gas.

CAUTION: Use pipe joint seal- ant that is resistant to liquid pe- troleum (LP) gas.

Install sediment trap in supply line as shown in Figure 13. Locate sediment trap where it is within reach for cleaning. Locate sedi- ment trap where trapped matter is not likely to freeze. A sediment trap traps moisture and contaminants. This keeps them from going into heater controls. If sediment trap is not installed or is installed wrong, heater may not run properly.

IMPORTANT: Hold pressure regulator with wrench when connecting it to gas piping and/or fittings

Pressure Regulator

Figure 12 - Installing Bottom Mounting Screw

CONNECTING TO GAS SUPPLY

![]() WARNING: This appliance re- quires a 3/8" NPT (National Pipe Thread) inlet connection to the pressure regulator.

WARNING: This appliance re- quires a 3/8" NPT (National Pipe Thread) inlet connection to the pressure regulator.

![]() WARNING: A qualified ser- vice person must connect heater to gas supply. Follow all local codes.

WARNING: A qualified ser- vice person must connect heater to gas supply. Follow all local codes.

![]() CAUTION:Neverconnectheater to private

CAUTION:Neverconnectheater to private

IMPORTANT: Check gas line pressure be- fore connecting heater to gas line. Gas line pressure must be no greater than 14 inches of water. If gas line pressure is higher, heater regulator damage could occur.

3/8" NPT

Pipe Nipple

Heater

Cabinet

Ground Joint Union | Tee Joint |

| |

Equipment | Reducer | Test | |

Shutoff | Bushing to | ||

Gauge | |||

Valve * | 1/8" NPT | ||

Connection * | |||

| 1/8" NPT | ||

From |

| ||

Gas Meter | Plug Tap |

|

(4" W.C. to |

|

10.5" W.C. | Tee Joint |

Pressure) |

|

3" Min. | Pipe Nipple Sediment |

| Trap |

| Cap |

Figure 13 - Gas Connection |

|

*A CSA/AGA

Continued

107294 | 9 |