INSTALLATION

Gas Line

11

INSTALLATION

Continued

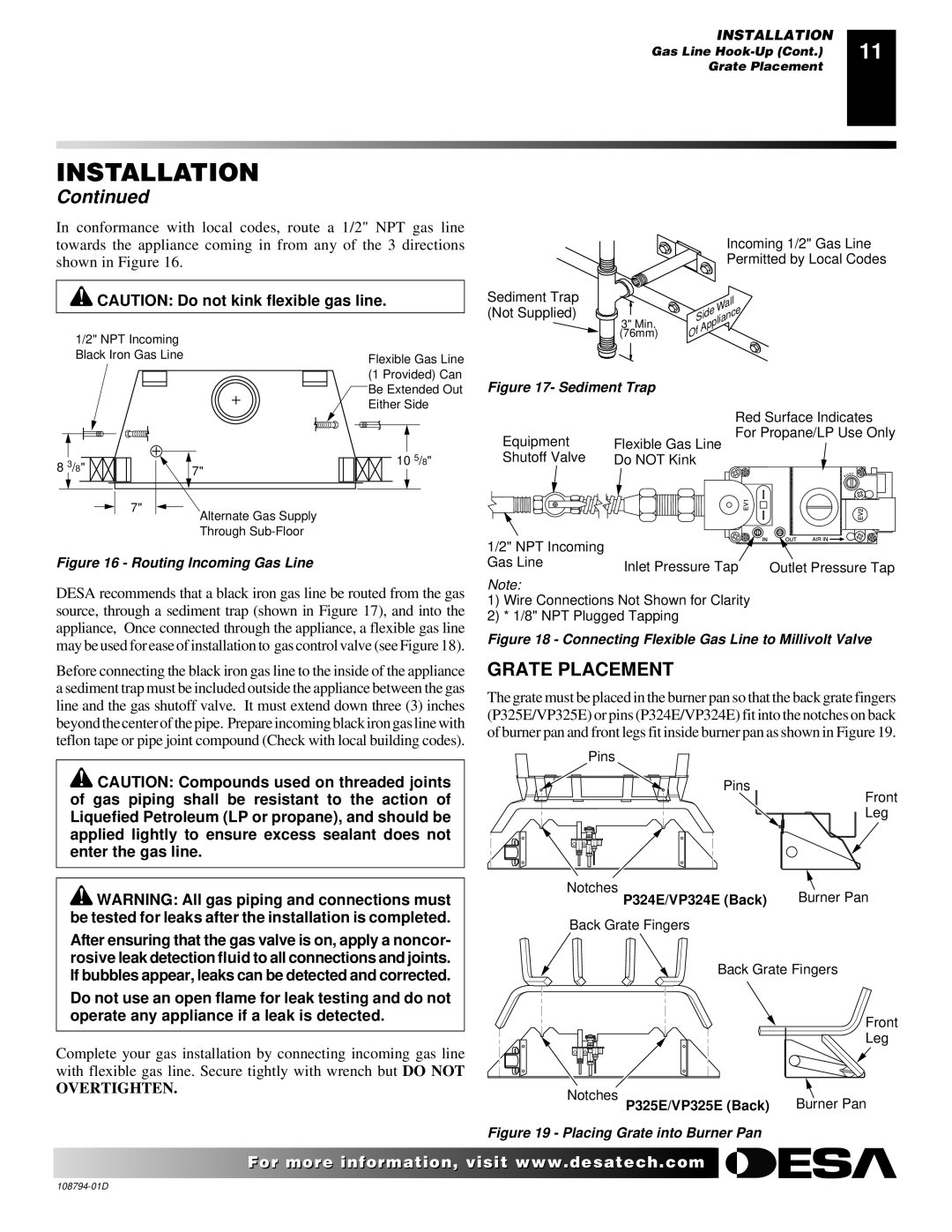

In conformance with local codes, route a 1/2" NPT gas line towards the appliance coming in from any of the 3 directions shown in Figure 16.

![]() CAUTION: Do not kink flexible gas line.

CAUTION: Do not kink flexible gas line.

|

|

|

|

| Incoming 1/2" Gas Line |

|

|

|

|

| Permitted by Local Codes |

Sediment Trap |

|

|

|

| all |

|

|

|

|

| |

(Not Supplied) |

| Side | W | ||

3" Min. |

| f | A | ppliance | |

(76mm) | O |

|

| ||

|

|

| |||

1/2" NPT Incoming

Black Iron Gas Line

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

8 | 3/8" |

|

|

|

|

|

|

|

| 7" | ||||

|

|

|

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

7"

Alternate Gas Supply Through

Flexible Gas Line

(1 Provided) Can

Be Extended Out

Either Side

105/8"

Figure 17- Sediment Trap | |

| Red Surface Indicates |

Equipment | For Propane/LP Use Only |

Flexible Gas Line | |

Shutoff Valve | Do NOT Kink |

Figure 16 - Routing Incoming Gas Line

DESA recommends that a black iron gas line be routed from the gas source, through a sediment trap (shown in Figure 17), and into the appliance, Once connected through the appliance, a flexible gas line may be used for ease of installation to gas control valve (see Figure 18).

Before connecting the black iron gas line to the inside of the appliance a sediment trap must be included outside the appliance between the gas line and the gas shutoff valve. It must extend down three (3) inches beyond the center of the pipe. Prepare incoming black iron gas line with teflon tape or pipe joint compound (Check with local building codes).

![]() CAUTION: Compounds used on threaded joints of gas piping shall be resistant to the action of Liquefied Petroleum (LP or propane), and should be applied lightly to ensure excess sealant does not enter the gas line.

CAUTION: Compounds used on threaded joints of gas piping shall be resistant to the action of Liquefied Petroleum (LP or propane), and should be applied lightly to ensure excess sealant does not enter the gas line.

1/2" NPT Incoming |

|

|

Gas Line | Inlet Pressure Tap | Outlet Pressure Tap |

|

Note:

1)Wire Connections Not Shown for Clarity

2)* 1/8" NPT Plugged Tapping

Figure 18 - Connecting Flexible Gas Line to Millivolt Valve

GRATE PLACEMENT

The grate must be placed in the burner pan so that the back grate fingers (P325E/VP325E) or pins (P324E/VP324E) fit into the notches on back of burner pan and front legs fit inside burner pan as shown in Figure 19.

Pins

Pins

Front

Leg

![]() WARNING: All gas piping and connections must be tested for leaks after the installation is completed.

WARNING: All gas piping and connections must be tested for leaks after the installation is completed.

After ensuring that the gas valve is on, apply a noncor- rosive leak detection fluid to all connections and joints. If bubbles appear, leaks can be detected and corrected.

Do not use an open flame for leak testing and do not operate any appliance if a leak is detected.

Complete your gas installation by connecting incoming gas line with flexible gas line. Secure tightly with wrench but DO NOT

OVERTIGHTEN.

Notches | Burner Pan |

P324E/VP324E (Back) | |

Back Grate Fingers |

|

Back Grate Fingers

Front

Leg

Notches | Burner Pan |

P325E/VP325E (Back) |

Figure 19 - Placing Grate into Burner Pan

![]()

![]()

![]()

![]() For more information, visit www.desatech.com

For more information, visit www.desatech.com