DESCRIPTION OF OPERATION (cont'd)

Outlet Pressure Gauge: The outlet pressure gauge indi- cates the air pressure available at the outlet side of the regulator. This pressure is controlled by the regulator and is always less or equal to the tank pressure. See “Operating Procedures”.

Tank Pressure Gauge: The tank pressure gauge indicates the reserve air pressure in the tank.

Regulator: The air pressure coming from the air tank is controlled by the regulator knob. Turn the knob clockwise to increase pressure and counterclockwise to decrease pres- sure. To avoid minor readjustment after making a change in pressure setting, always approach the desired pressure from a lower pressure. When reducing from a higher to a lower setting, first reduce to some pressure less than that desired, then bring up to the desired pressure. Depending on the air requirements of each particular accessory, the outlet regu- lated air pressure may have to be adjusted while you are operating the accessory.

Installing Handle

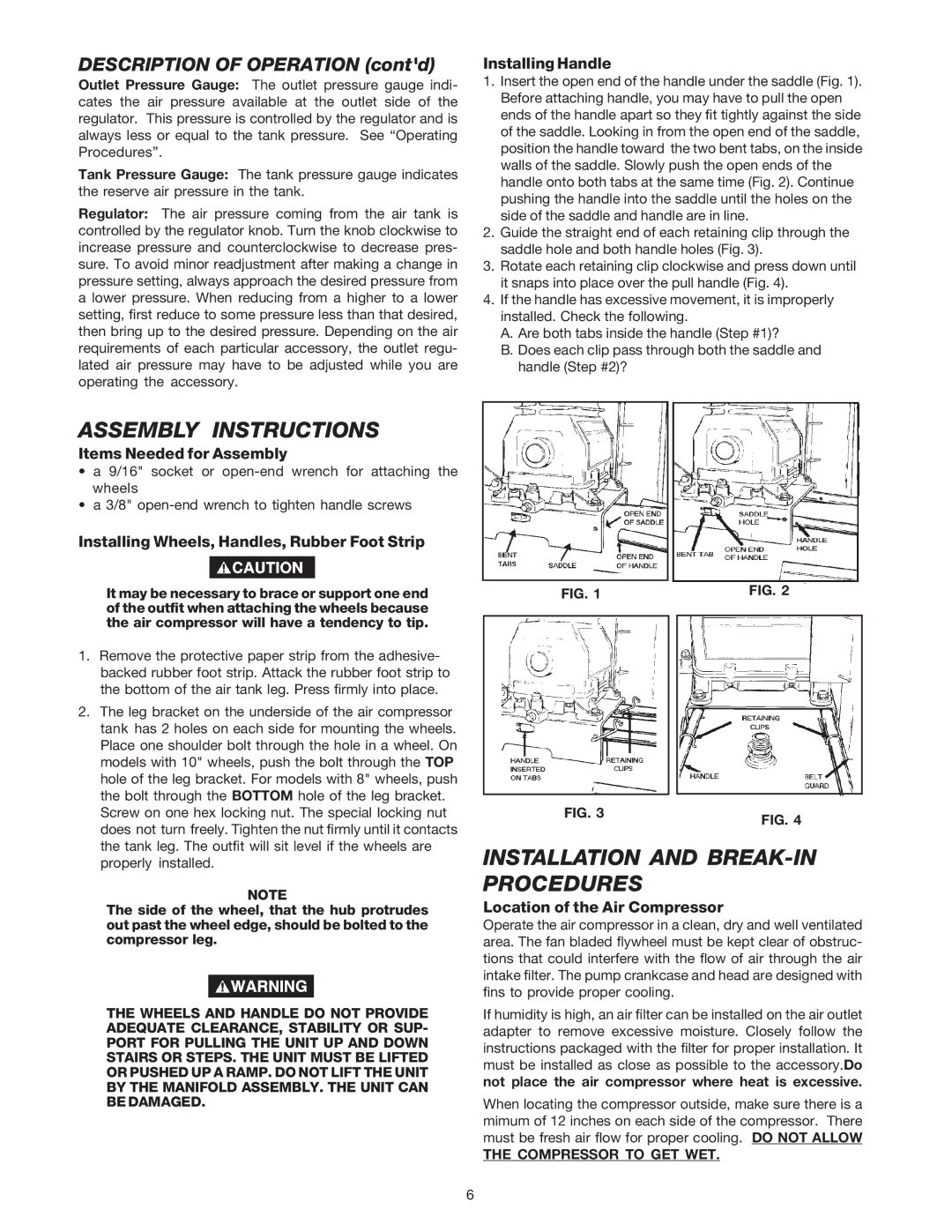

1.Insert the open end of the handle under the saddle (Fig. 1). Before attaching handle, you may have to pull the open ends of the handle apart so they fit tightly against the side of the saddle. Looking in from the open end of the saddle, position the handle toward the two bent tabs, on the inside walls of the saddle. Slowly push the open ends of the handle onto both tabs at the same time (Fig. 2). Continue pushing the handle into the saddle until the holes on the side of the saddle and handle are in line.

2.Guide the straight end of each retaining clip through the saddle hole and both handle holes (Fig. 3).

3.Rotate each retaining clip clockwise and press down until it snaps into place over the pull handle (Fig. 4).

4.If the handle has excessive movement, it is improperly installed. Check the following.

A.Are both tabs inside the handle (Step #1)?

B.Does each clip pass through both the saddle and handle (Step #2)?

ASSEMBLY INSTRUCTIONS

Items Needed for Assembly

•a 9/16" socket or

•a 3/8"

Installing Wheels, Handles, Rubber Foot Strip

It may be necessary to brace or support one end of the outfit when attaching the wheels because the air compressor will have a tendency to tip.

1.Remove the protective paper strip from the adhesive- backed rubber foot strip. Attack the rubber foot strip to the bottom of the air tank leg. Press firmly into place.

2.The leg bracket on the underside of the air compressor tank has 2 holes on each side for mounting the wheels. Place one shoulder bolt through the hole in a wheel. On models with 10" wheels, push the bolt through the TOP hole of the leg bracket. For models with 8" wheels, push the bolt through the BOTTOM hole of the leg bracket.

Screw on one hex locking nut. The special locking nut does not turn freely. Tighten the nut firmly until it contacts the tank leg. The outfit will sit level if the wheels are properly installed.

NOTE

The side of the wheel, that the hub protrudes out past the wheel edge, should be bolted to the compressor leg.

THE WHEELS AND HANDLE DO NOT PROVIDE ADEQUATE CLEARANCE, STABILITY OR SUP- PORT FOR PULLING THE UNIT UP AND DOWN STAIRS OR STEPS. THE UNIT MUST BE LIFTED OR PUSHED UP A RAMP. DO NOT LIFT THE UNIT BY THE MANIFOLD ASSEMBLY. THE UNIT CAN BE DAMAGED.

FIG. 1 | FIG. 2 | |

|

|

|

|

|

|

FIG. 3 | FIG. 4 |

|

INSTALLATION AND BREAK-IN PROCEDURES

Location of the Air Compressor

Operate the air compressor in a clean, dry and well ventilated area. The fan bladed flywheel must be kept clear of obstruc- tions that could interfere with the flow of air through the air intake filter. The pump crankcase and head are designed with fins to provide proper cooling.

If humidity is high, an air filter can be installed on the air outlet adapter to remove excessive moisture. Closely follow the instructions packaged with the filter for proper installation. It must be installed as close as possible to the accessory.Do not place the air compressor where heat is excessive.

When locating the compressor outside, make sure there is a mimum of 12 inches on each side of the compressor. There must be fresh air flow for proper cooling. DO NOT ALLOW

THE COMPRESSOR TO GET WET.

6