TRI TOOL INC.

OPERATION

Read the operating instructions carefully before attempting to operate the Model 550 Tube Severing Tool.

Be sure to use eye protection at all times when operating the Model 550.

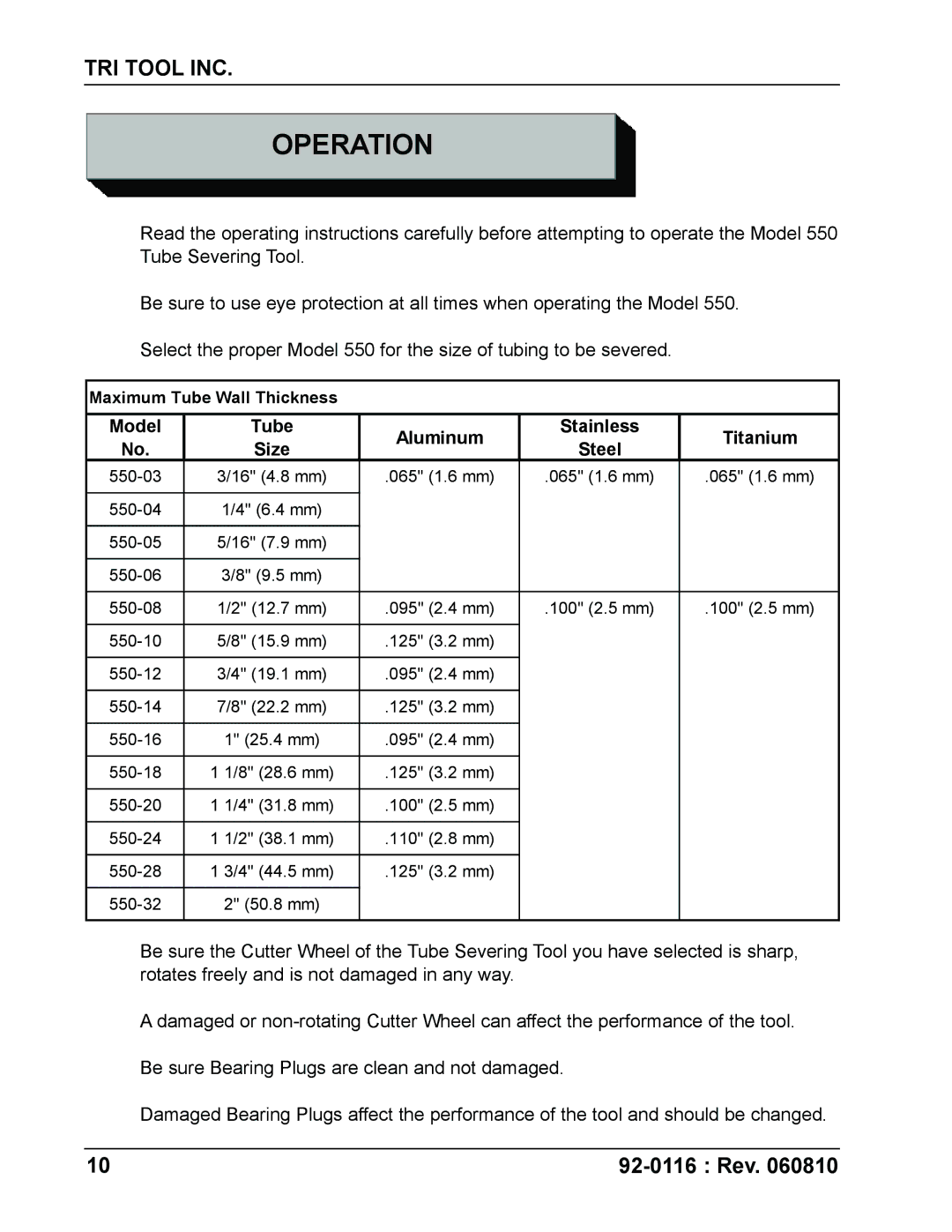

Select the proper Model 550 for the size of tubing to be severed.

Maximum Tube Wall Thickness

Model |

| Tube | Aluminum | Stainless | Titanium |

No. |

| Size | Steel | ||

|

|

| |||

3/16" (4.8 mm) | .065" (1.6 mm) | .065" (1.6 mm) | .065" (1.6 mm) | ||

|

|

|

|

|

|

| 1/4" (6.4 mm) |

|

|

| |

|

|

|

|

| |

5/16" (7.9 mm) |

|

|

| ||

|

|

|

|

|

|

| 3/8" (9.5 mm) |

|

|

| |

|

|

|

|

| |

1/2" (12.7 mm) | .095" (2.4 mm) | .100" (2.5 mm) | .100" (2.5 mm) | ||

|

|

|

|

| |

5/8" (15.9 mm) | .125" (3.2 mm) |

|

| ||

|

|

|

|

| |

3/4" (19.1 mm) | .095" (2.4 mm) |

|

| ||

|

|

|

|

| |

7/8" (22.2 mm) | .125" (3.2 mm) |

|

| ||

|

|

|

|

|

|

| 1" (25.4 mm) | .095" (2.4 mm) |

|

| |

|

|

|

|

|

|

1 | 1/8" (28.6 mm) | .125" (3.2 mm) |

|

| |

|

|

|

|

|

|

1 | 1/4" (31.8 mm) | .100" (2.5 mm) |

|

| |

|

|

|

|

|

|

1 | 1/2" (38.1 mm) | .110" (2.8 mm) |

|

| |

|

|

|

|

|

|

1 | 3/4" (44.5 mm) | .125" (3.2 mm) |

|

| |

|

|

|

|

|

|

| 2" (50.8 mm) |

|

|

| |

|

|

|

|

|

|

Be sure the Cutter Wheel of the Tube Severing Tool you have selected is sharp, rotates freely and is not damaged in any way.

A damaged or

Be sure Bearing Plugs are clean and not damaged.

Damaged Bearing Plugs affect the performance of the tool and should be changed.

10 |