FIG. 7 | FIG. 8 |

English

only by the plastic or rubber handle and housing to prevent electric shock if you saw into a “live” wire.

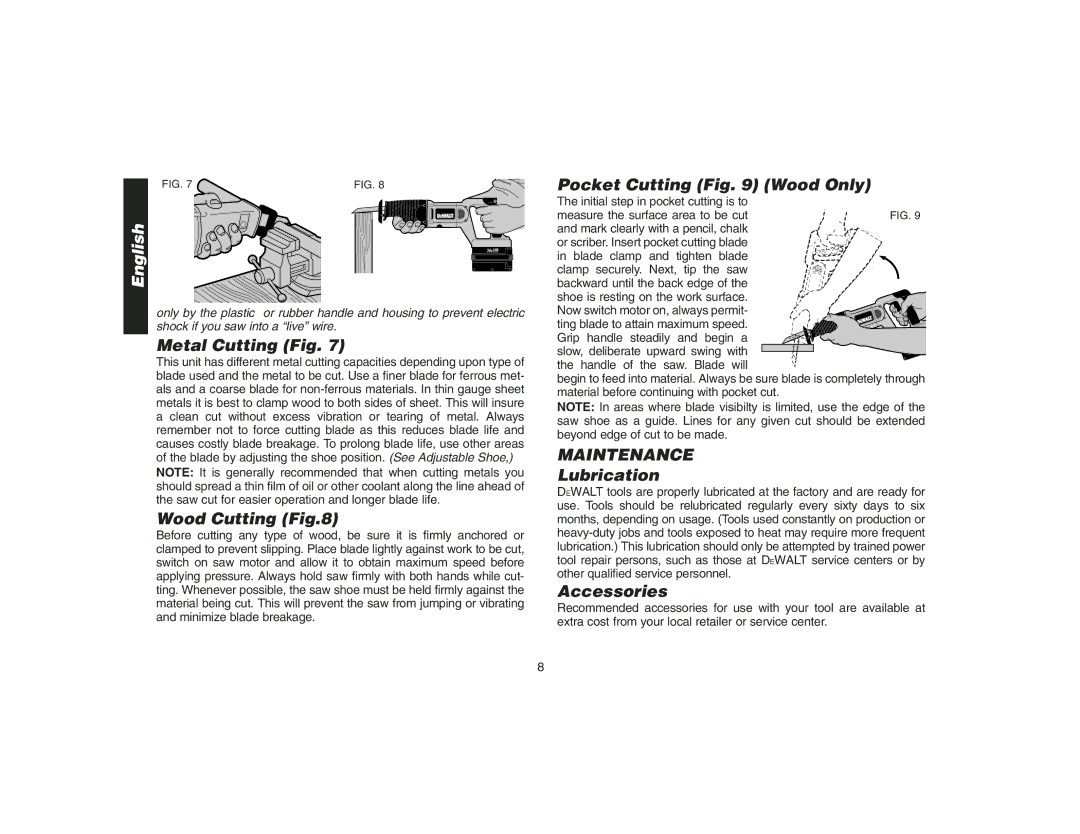

Metal Cutting (Fig. 7)

This unit has different metal cutting capacities depending upon type of blade used and the metal to be cut. Use a finer blade for ferrous met- als and a coarse blade for

NOTE: It is generally recommended that when cutting metals you should spread a thin film of oil or other coolant along the line ahead of the saw cut for easier operation and longer blade life.

Wood Cutting (Fig.8)

Before cutting any type of wood, be sure it is firmly anchored or clamped to prevent slipping. Place blade lightly against work to be cut, switch on saw motor and allow it to obtain maximum speed before applying pressure. Always hold saw firmly with both hands while cut- ting. Whenever possible, the saw shoe must be held firmly against the material being cut. This will prevent the saw from jumping or vibrating and minimize blade breakage.

Pocket Cutting (Fig. 9) (Wood Only)

The initial step in pocket cutting is to measure the surface area to be cut

and mark clearly with a pencil, chalk or scriber. Insert pocket cutting blade

in blade clamp and tighten blade clamp securely. Next, tip the saw backward until the back edge of the

shoe is resting on the work surface. Now switch motor on, always permit- ting blade to attain maximum speed. Grip handle steadily and begin a slow, deliberate upward swing with the handle of the saw. Blade will

begin to feed into material. Always be sure blade is completely through material before continuing with pocket cut.

NOTE: In areas where blade visibilty is limited, use the edge of the saw shoe as a guide. Lines for any given cut should be extended beyond edge of cut to be made.

MAINTENANCE

Lubrication

DEWALT tools are properly lubricated at the factory and are ready for use. Tools should be relubricated regularly every sixty days to six months, depending on usage. (Tools used constantly on production or

Accessories

Recommended accessories for use with your tool are available at extra cost from your local retailer or service center.

8