•Pull by the plug rather than the cord when disconnecting the charger. This will reduce the risk of damage to the electric plug and cord.

•Make sure that the cord is located so that it will not be stepped on, tripped over or otherwise subjected to damage or stress.

•Do not use an extension cord unless it is absolutely necessary. Use of improper extension cord could result in risk of fire, electric shock or electrocution.

•When operating a charger outdoors, always provide a dry location and use an extension cord suitable for outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

•An extension cord must have adequate wire size (AWG or American Wire Gauge) for safety. The smaller the gauge number of the wire, the greater the capacity of the cable, that is, 16 gauge has more capacity than 18 gauge. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. When using more than one extension to make up the total length, be sure each individual extension contains at least the minimum wire size. The following table shows the correct size to use depending on cord length and nameplate ampere rating. If in doubt, use the next heavier gauge. The lower the gauge number, the heavier the cord.

Minimum Gauge for Cord Sets

Ampere Rating | Volts | Total Length of Cord in Feet (meters) | ||||

120V | 25 (7.6) | 50 (15.2) | 100 (30.5) | 150 (45.7) | ||

|

| 240V | 50 (15.2) | 100 (30.5) | 200 (61.0) | 300 (91.4) |

More | Not More |

|

| AWG |

|

|

Than | Than |

|

|

|

| |

|

|

|

|

| ||

0 | 6 |

| 18 | 16 | 16 | 14 |

6 | 10 |

| 18 | 16 | 14 | 12 |

10 | 12 |

| 16 | 16 | 14 | 12 |

12 | 16 |

| 14 | 12 | Not Recommended | |

FIG. 1

F ![]()

CE

B

DAI

FIG. 2 | G | FIG. 3 |

|

|

G

![]() G

G

FIG. 4 | H |

J

•Do not place any object on top of the charger or place the charger on a soft surface that might block the ventilation slots and result in excessive internal heat. Place the charger in a position away from any heat source. The charger is ventilated through slots in the top and the bottom of the housing.

•Do not operate the charger with a damaged cord or plug.

•Do not operate the charger if it has received a sharp blow, been dropped or otherwise damaged in any way. Take it to an authorized service center.

•Do not disassemble the charger; take it to an authorized service center when service or repair is required. Incorrect reassembly may result in a risk of electric shock, electrocution or fire.

•Disconnect the charger from the outlet before attempting any cleaning. This will reduce the risk of electric shock. Removing the battery pack will not reduce this risk.

•NEVER attempt to connect 2 chargers together.

•The charger is designed to operate on standard 120V household electrical power. Do not attempt to use it on any other voltage. This does not apply to the vehicular charger.

Chargers

Your tool uses a DEWALT charger. Be sure to read all safety instructions before using your charger. Consult the chart at the end of this manual for compatibility of chargers and battery packs.

Charging Procedure (Fig. 2)

1.Plug the charger into an appropriate outlet before inserting the battery pack.

2.Insert the battery pack (G) into the charger, as shown in Figure 2, making sure the pack is fully seated in charger. The red (charging) light will blink continuously, indicating that the charging process has started.

3.The completion of charge will be indicated by the red light remaining ON continuously. The pack is fully charged and may be used at this time or left in the charger.

Indicator Light Operation

DCB101

PACK CHARGING ![]()

![]()

PACK CHARGED

![]() HOT/COLD DELAY

HOT/COLD DELAY

x PROBLEM PACK OR CHARGER

PROBLEM POWERLINE

DCB107, DCB112

![]()

![]()

![]()

![]()

![]()

![]() PACK CHARGING

PACK CHARGING

![]()

![]()

![]()

![]()

![]() PACK CHARGED

PACK CHARGED

![]()

![]()

![]()

![]()

![]()

![]() HOT/COLD DELAY

HOT/COLD DELAY

Charge Indicators

This charger is designed to detect certain problems that can arise. Problems are indicated by the red light flashing at a fast rate. If this occurs,

HOT/COLD DELAY

DCB101

This charger has a hot/cold delay feature: when the charger detects a battery that is hot, it automatically starts a delay, suspending charging until the battery has cooled. After the battery has cooled, the charger automatically switches to the pack charging mode. This feature ensures maximum battery life. The red light flashes long, then short while in the hot/cold delay mode.

DCB107, DCB112

The DCB107 and DCB112 chargers have a hot/cold delay feature. When the charger detects a battery that is hot, it automatically delays charging until the battery has cooled. When the charger detects a battery that is cold, it automatically delays charging until the battery has warmed.

The red light will continue to blink, but a yellow indicator light will be illuminated during this operation. Once the battery has cooled, the yellow light will turn off and the charger will resume the charging procedure.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the charge indicator showing Pack Charged.

WEAK BATTERY PACKS: Weak batteries will continue to function but should not be expected to perform as much work.

FAULTY BATTERY PACKS: This charger will not charge a faulty battery pack. The charger will indicate faulty battery pack by refusing to light or by displaying problem pack or charger. NOTE: This could also mean a problem with a charger.

PROBLEM POWER LINE

Some chargers have a Problem Power Line indicator. When the charger is used with some portable power sources such as generators or sources that convert DC to AC, the charger may temporarily suspend operation, flashing the red light with two fast blinks followed by a pause. This indicates the power source is out of limits.

Wall Mounting

DCB107, DCB112

These chargers are designed to be wall mountable or to sit upright on a table or work surface. If wall mounting, locate the charger within reach of an electrical outlet. Mount the charger securely using drywall screws at least 1” (25.4 mm) long, screwed into wood to an optimal depth leaving approximately 7/32” (5.5 mm) of the screw exposed.

Important Charging Notes

1.Longest life and best performance can be obtained if the battery pack is charged when the air temperature is between 65 °F and 75 °F (18° – 24 °C). DO NOT charge the battery pack in an air temperature below +40 °F (+4.5 °C), or above +105 °F (+40.5 °C). This is important and will prevent serious damage to the battery pack.

2.The charger and battery pack may become warm to the touch while charging. This is a normal condition, and does not indicate a problem. To facilitate the cooling of the battery pack after use, avoid placing the charger or battery pack in a warm environment such as in a metal shed or an uninsulated trailer.

3.A cold battery pack will charge at about half the rate of a warm battery pack. The battery pack will charge at that slower rate throughout the entire charging cycle and will not return to maximum charge rate even if the battery pack warms.

4.If the battery pack does not charge properly:

a.Check operation of receptacle by plugging in a lamp or other appliance;

b.Check to see if receptacle is connected to a light switch which turns power off when you turn out the lights;

c.Move the charger and battery pack to a location where the surrounding air temperature is approximately 65 °F – 75 °F (18° – 24 °C);

d.If charging problems persist, take the tool, battery pack and charger to your local service center.

5.The battery pack should be recharged when it fails to produce sufficient power on jobs which were easily done previously. DO NOT CONTINUE to use under these conditions. Follow the charging procedure. You may also charge a partially used pack whenever you desire with no adverse effect on the battery pack.

6.Foreign materials of a conductive nature such as, but not limited to, grinding dust, metal chips, steel wool, aluminum foil, or any buildup of metallic particles should be kept away from charger cavities. Always unplug the charger from the power supply when there is no battery pack in the cavity. Unplug the charger before attempting to clean.

7.Do not freeze or immerse the charger in water or any other liquid.

![]() WARNING: Shock hazard. Don’t allow any liquid to get inside the charger. Electric shock may result.

WARNING: Shock hazard. Don’t allow any liquid to get inside the charger. Electric shock may result.

![]() WARNING: Burn hazard. Do not submerge the battery pack in any liquid or allow any liquid to enter the battery pack. Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack breaks or cracks, return to a service center for recycling.

WARNING: Burn hazard. Do not submerge the battery pack in any liquid or allow any liquid to enter the battery pack. Never attempt to open the battery pack for any reason. If the plastic housing of the battery pack breaks or cracks, return to a service center for recycling.

Storage Recommendations

1.The best storage place is one that is cool and dry, away from direct sunlight and excess heat or cold.

2.For long storage, it is recommended to store a fully charged battery pack in a cool dry place out of the charger for optimal results.

NOTE: Battery packs should not be stored completely depleted of charge. The battery pack will need to be recharged before use.

![]() I

I

FIG. 5

SAVE THESE INSTRUCTIONS FOR FUTURE USE

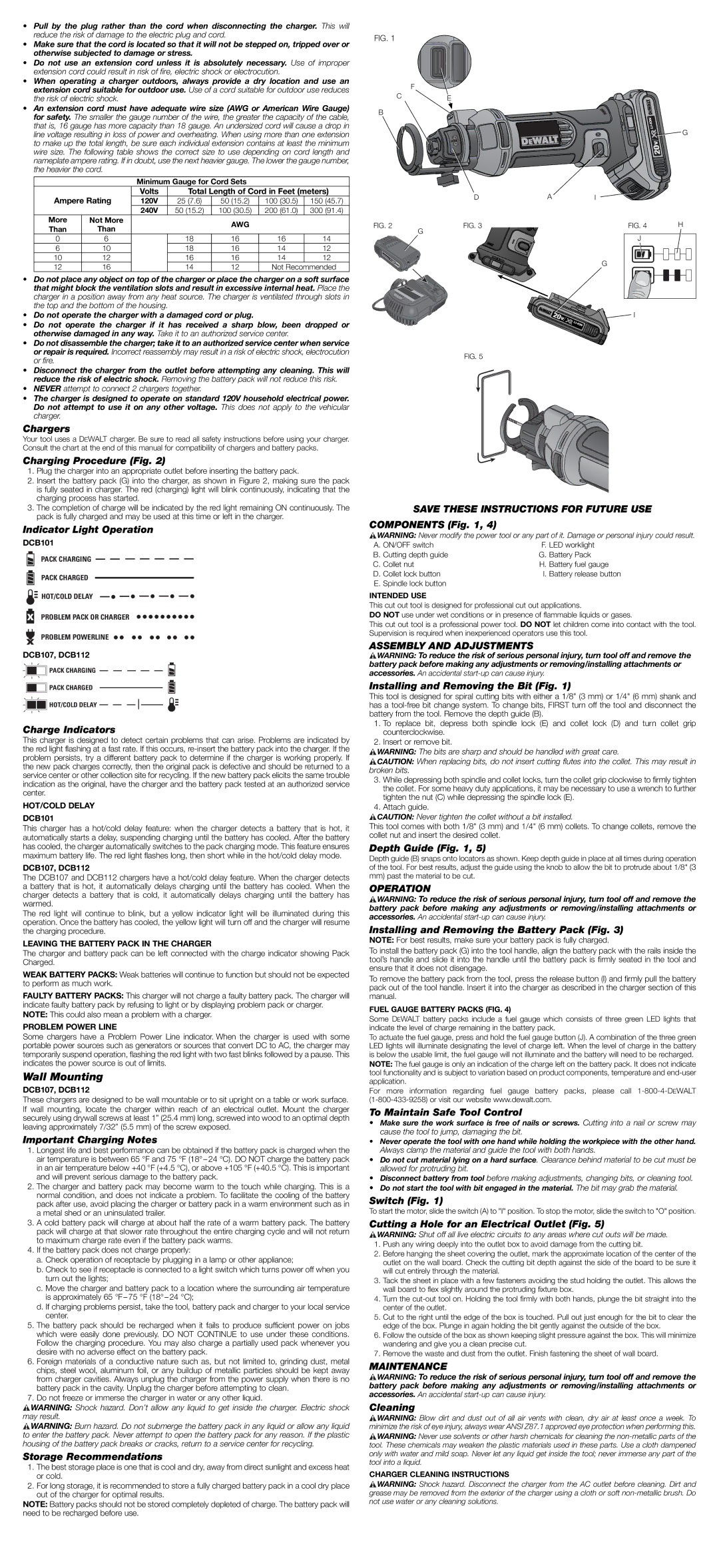

COMPONENTS (Fig. 1, 4)

![]() WARNING: Never modify the power tool or any part of it. Damage or personal injury could result.

WARNING: Never modify the power tool or any part of it. Damage or personal injury could result.

A. ON/OFF switch | F. LED worklight |

B. Cutting depth guide | G. Battery Pack |

C. Collet nut | H. Battery fuel gauge |

D. Collet lock button | I. Battery release button |

E. Spindle lock button |

|

INTENDED USE

This cut out tool is designed for professional cut out applications.

DO NOT use under wet conditions or in presence of flammable liquids or gases.

This cut out tool is a professional power tool. DO NOT let children come into contact with the tool. Supervision is required when inexperienced operators use this tool.

ASSEMBLY AND ADJUSTMENTS

![]() WARNING: To reduce the risk of serious personal injury, turn tool off and remove the battery pack before making any adjustments or removing/installing attachments or accessories. An accidental

WARNING: To reduce the risk of serious personal injury, turn tool off and remove the battery pack before making any adjustments or removing/installing attachments or accessories. An accidental

Installing and Removing the Bit (Fig. 1)

This tool is designed for spiral cutting bits with either a 1/8" (3 mm) or 1/4" (6 mm) shank and has a

1.To replace bit, depress both spindle lock (E) and collet lock (D) and turn collet grip counterclockwise.

2.Insert or remove bit.

![]() WARNING: The bits are sharp and should be handled with great care.

WARNING: The bits are sharp and should be handled with great care.

![]() CAUTION: When replacing bits, do not insert cutting flutes into the collet. This may result in broken bits.

CAUTION: When replacing bits, do not insert cutting flutes into the collet. This may result in broken bits.

3.While depressing both spindle and collet locks, turn the collet grip clockwise to firmly tighten the collet. For some heavy duty applications, it may be necessary to use a wrench to further tighten the nut (C) while depressing the spindle lock (E).

4.Attach guide.

![]() CAUTION: Never tighten the collet without a bit installed.

CAUTION: Never tighten the collet without a bit installed.

This tool comes with both 1/8" (3 mm) and 1/4" (6 mm) collets. To change collets, remove the collet nut and insert the desired collet.

Depth Guide (Fig. 1, 5)

Depth guide (B) snaps onto locators as shown. Keep depth guide in place at all times during operation of the tool. For best results, adjust the guide using the knob to allow the bit to protrude about 1/8" (3

mm)past the material to be cut.

OPERATION

![]() WARNING: To reduce the risk of serious personal injury, turn tool off and remove the battery pack before making any adjustments or removing/installing attachments or accessories. An accidental

WARNING: To reduce the risk of serious personal injury, turn tool off and remove the battery pack before making any adjustments or removing/installing attachments or accessories. An accidental

Installing and Removing the Battery Pack (Fig. 3)

NOTE: For best results, make sure your battery pack is fully charged.

To install the battery pack (G) into the tool handle, align the battery pack with the rails inside the tool’s handle and slide it into the handle until the battery pack is firmly seated in the tool and ensure that it does not disengage.

To remove the battery pack from the tool, press the release button (I) and firmly pull the battery pack out of the tool handle. Insert it into the charger as described in the charger section of this manual.

FUEL GAUGE BATTERY PACKS (FIG. 4)

Some DEWALT battery packs include a fuel gauge which consists of three green LED lights that indicate the level of charge remaining in the battery pack.

To actuate the fuel gauge, press and hold the fuel gauge button (J). A combination of the three green LED lights will illuminate designating the level of charge left. When the level of charge in the battery is below the usable limit, the fuel gauge will not illuminate and the battery will need to be recharged. NOTE: The fuel gauge is only an indication of the charge left on the battery pack. It does not indicate tool functionality and is subject to variation based on product components, temperature and

For more information regarding fuel gauge battery packs, please call

To Maintain Safe Tool Control

•Make sure the work surface is free of nails or screws. Cutting into a nail or screw may cause the tool to jump, damaging the bit.

•Never operate the tool with one hand while holding the workpiece with the other hand. Always clamp the material and guide the tool with both hands.

•Do not cut material lying on a hard surface. Clearance behind material to be cut must be allowed for protruding bit.

•Disconnect battery from tool before making adjustments, changing bits, or cleaning tool.

•Do not start the tool with bit engaged in the material. The bit may grab the material.

Switch (Fig. 1)

To start the motor, slide the switch (A) to "I" position. To stop the motor, slide the switch to "O" position.

Cutting a Hole for an Electrical Outlet (Fig. 5)

![]() WARNING: Shut off all live electric circuits to any areas where cut outs will be made.

WARNING: Shut off all live electric circuits to any areas where cut outs will be made.

1.Push any wiring deeply into the outlet box to avoid damage from the cutting bit.

2.Before hanging the sheet covering the outlet, mark the approximate location of the center of the outlet on the wall board. Check the cutting bit depth against the side of the board to be sure it will cut entirely through the material.

3.Tack the sheet in place with a few fasteners avoiding the stud holding the outlet. This allows the wall board to flex slightly around the protruding fixture box.

4.Turn the

5.Cut to the right until the edge of the box is touched. Pull out just enough for the bit to clear the edge of the box. Plunge in again holding the bit gently against the outside of the box.

6.Follow the outside of the box as shown keeping slight pressure against the box. This will minimize wandering and give you a clean precise cut.

7.Remove the waste and dust from the outlet. Finish fastening the sheet of wall board.

MAINTENANCE

![]() WARNING: To reduce the risk of serious personal injury, turn tool off and remove the battery pack before making any adjustments or removing/installing attachments or accessories. An accidental

WARNING: To reduce the risk of serious personal injury, turn tool off and remove the battery pack before making any adjustments or removing/installing attachments or accessories. An accidental

Cleaning

![]() WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week. To minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when performing this.

WARNING: Blow dirt and dust out of all air vents with clean, dry air at least once a week. To minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection when performing this.

![]() WARNING: Never use solvents or other harsh chemicals for cleaning the

WARNING: Never use solvents or other harsh chemicals for cleaning the

CHARGER CLEANING INSTRUCTIONS

![]() WARNING: Shock hazard. Disconnect the charger from the AC outlet before cleaning. Dirt and grease may be removed from the exterior of the charger using a cloth or soft

WARNING: Shock hazard. Disconnect the charger from the AC outlet before cleaning. Dirt and grease may be removed from the exterior of the charger using a cloth or soft