NOTE: Use lower speeds for starting holes without a center punch, drilling in metal or plastics, driving screws or drilling ceramics. Higher speeds are better for drilling wood and composition boards, and for using abrasive and polishing accessories.

THE REVERSING LEVER

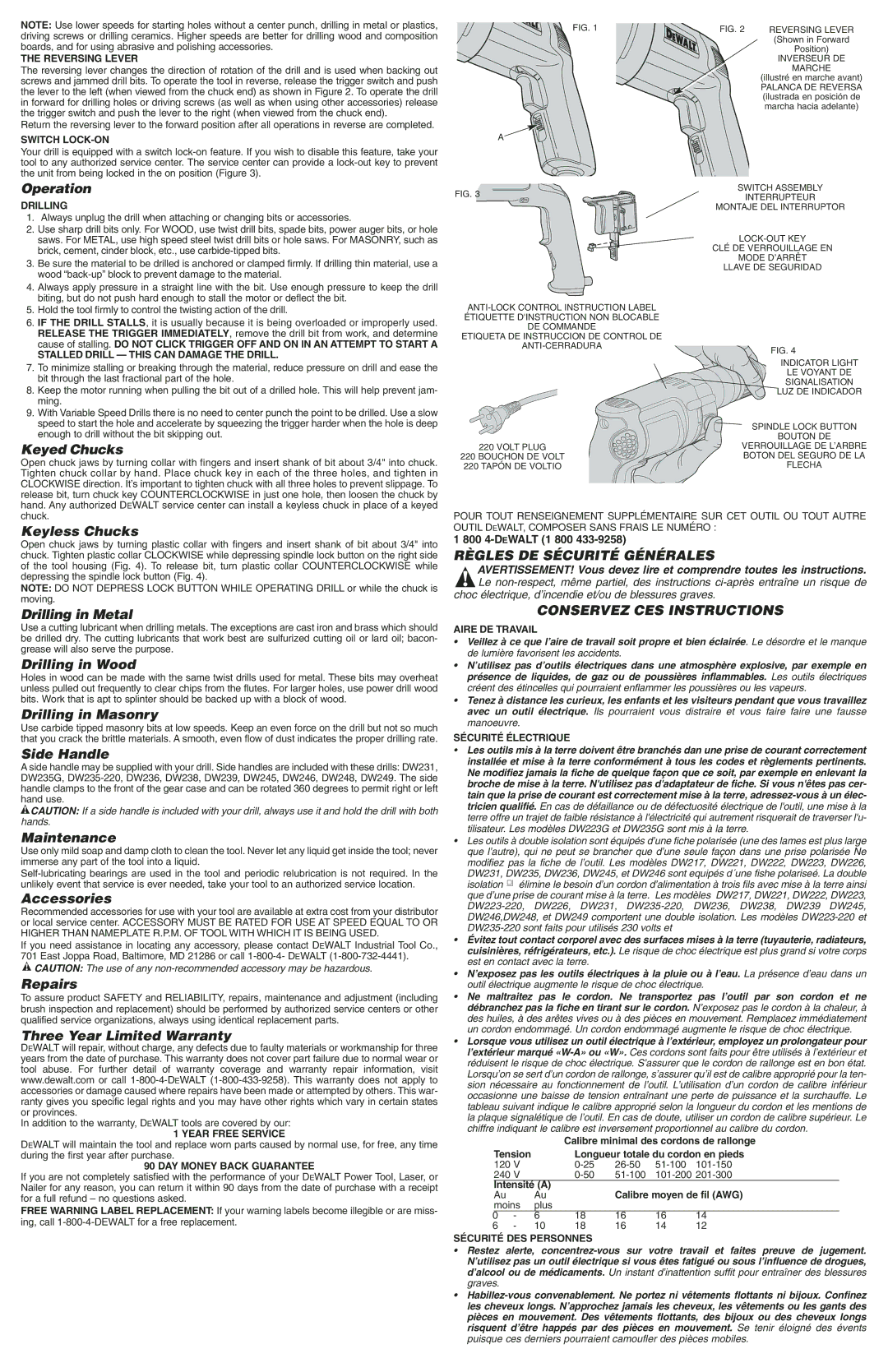

The reversing lever changes the direction of rotation of the drill and is used when backing out screws and jammed drill bits. To operate the tool in reverse, release the trigger switch and push the lever to the left (when viewed from the chuck end) as shown in Figure 2. To operate the drill in forward for drilling holes or driving screws (as well as when using other accessories) release the trigger switch and push the lever to the right (when viewed from the chuck end).

Return the reversing lever to the forward position after all operations in reverse are completed.

SWITCH LOCK-ON

Your drill is equipped with a switch

Operation

DRILLING

1.Always unplug the drill when attaching or changing bits or accessories.

2.Use sharp drill bits only. For WOOD, use twist drill bits, spade bits, power auger bits, or hole saws. For METAL, use high speed steel twist drill bits or hole saws. For MASONRY, such as brick, cement, cinder block, etc., use

3.Be sure the material to be drilled is anchored or clamped firmly. If drilling thin material, use a wood

4.Always apply pressure in a straight line with the bit. Use enough pressure to keep the drill biting, but do not push hard enough to stall the motor or deflect the bit.

5.Hold the tool firmly to control the twisting action of the drill.

6.IF THE DRILL STALLS, it is usually because it is being overloaded or improperly used. RELEASE THE TRIGGER IMMEDIATELY, remove the drill bit from work, and determine cause of stalling. DO NOT CLICK TRIGGER OFF AND ON IN AN ATTEMPT TO START A

STALLED DRILL — THIS CAN DAMAGE THE DRILL.

7.To minimize stalling or breaking through the material, reduce pressure on drill and ease the bit through the last fractional part of the hole.

8.Keep the motor running when pulling the bit out of a drilled hole. This will help prevent jam- ming.

9.With Variable Speed Drills there is no need to center punch the point to be drilled. Use a slow speed to start the hole and accelerate by squeezing the trigger harder when the hole is deep enough to drill without the bit skipping out.

Keyed Chucks

Open chuck jaws by turning collar with fingers and insert shank of bit about 3/4" into chuck. Tighten chuck collar by hand. Place chuck key in each of the three holes, and tighten in CLOCKWISE direction. It’s important to tighten chuck with all three holes to prevent slippage. To release bit, turn chuck key COUNTERCLOCKWISE in just one hole, then loosen the chuck by hand. Any authorized DEWALT service center can install a keyless chuck in place of a keyed

![]() FIG. 1

FIG. 1

A

FIG. 3

ETIQUETA DE INSTRUCCION DE CONTROL DE

220 VOLT PLUG

220 BOUCHON DE VOLT

220 TAPÓN DE VOLTIO

FIG. 2 REVERSING LEVER (Shown in Forward

Position)

INVERSEUR DE

MARCHE

(illustré en marche avant)

PALANCA DE REVERSA (ilustrada en posición de marcha hacia adelante)

SWITCH ASSEMBLY

INTERRUPTEUR

MONTAJE DEL INTERRUPTOR

CLÉ DE VERROUILLAGE EN

MODE D’ARRÊT

LLAVE DE SEGURIDAD

FIG. 4

INDICATOR LIGHT

LE VOYANT DE

SIGNALISATION

LUZ DE INDICADOR

SPINDLE LOCK BUTTON BOUTON DE

VERROUILLAGE DE L’ARBRE BOTON DEL SEGURO DE LA FLECHA

chuck.

Keyless Chucks

Open chuck jaws by turning plastic collar with fingers and insert shank of bit about 3/4" into chuck. Tighten plastic collar CLOCKWISE while depressing spindle lock button on the right side of the tool housing (Fig. 4). To release bit, turn plastic collar COUNTERCLOCKWISE while depressing the spindle lock button (Fig. 4).

NOTE: DO NOT DEPRESS LOCK BUTTON WHILE OPERATING DRILL or while the chuck is moving.

Drilling in Metal

Use a cutting lubricant when drilling metals. The exceptions are cast iron and brass which should be drilled dry. The cutting lubricants that work best are sulfurized cutting oil or lard oil; bacon- grease will also serve the purpose.

Drilling in Wood

Holes in wood can be made with the same twist drills used for metal. These bits may overheat unless pulled out frequently to clear chips from the flutes. For larger holes, use power drill wood bits. Work that is apt to splinter should be backed up with a block of wood.

Drilling in Masonry

Use carbide tipped masonry bits at low speeds. Keep an even force on the drill but not so much that you crack the brittle materials. A smooth, even flow of dust indicates the proper drilling rate.

Side Handle

A side handle may be supplied with your drill. Side handles are included with these drills: DW231, DW235G,

![]() CAUTION: If a side handle is included with your drill, always use it and hold the drill with both hands.

CAUTION: If a side handle is included with your drill, always use it and hold the drill with both hands.

Maintenance

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid.

Accessories

Recommended accessories for use with your tool are available at extra cost from your distributor or local service center. ACCESSORY MUST BE RATED FOR USE AT SPEED EQUAL TO OR HIGHER THAN NAMEPLATE R.P.M. OF TOOL WITH WHICH IT IS BEING USED.

If you need assistance in locating any accessory, please contact DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286 or call

![]() CAUTION: The use of any

CAUTION: The use of any

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush inspection and replacement) should be performed by authorized service centers or other qualified service organizations, always using identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three years from the date of purchase. This warranty does not cover part failure due to normal wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit www.dewalt.com or call

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt for a full refund – no questions asked.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are miss- ing, call

POUR TOUT RENSEIGNEMENT SUPPLÉMENTAIRE SUR CET OUTIL OU TOUT AUTRE OUTIL DEWALT, COMPOSER SANS FRAIS LE NUMÉRO :

1 800

RÈGLES DE SÉCURITÉ GÉNÉRALES

AVERTISSEMENT! Vous devez lire et comprendre toutes les instructions. Le

choc électrique, d’incendie et/ou de blessures graves.

CONSERVEZ CES INSTRUCTIONS

AIRE DE TRAVAIL

•Veillez à ce que l’aire de travail soit propre et bien éclairée. Le désordre et le manque de lumière favorisent les accidents.

•N’utilisez pas d’outils électriques dans une atmosphère explosive, par exemple en présence de liquides, de gaz ou de poussières inflammables. Les outils électriques créent des étincelles qui pourraient enflammer les poussières ou les vapeurs.

•Tenez à distance les curieux, les enfants et les visiteurs pendant que vous travaillez avec un outil électrique. Ils pourraient vous distraire et vous faire faire une fausse manoeuvre.

SÉCURITÉ ÉLECTRIQUE

•Les outils mis à la terre doivent être branchés dan une prise de courant correctement installée et mise à la terre conformément à tous les codes et règlements pertinents. Ne modifiez jamais la fiche de quelque façon que ce soit, par exemple en enlevant la broche de mise à la terre. N'utilisez pas d'adaptateur de fiche. Si vous n'êtes pas cer- tain que la prise de courant est correctement mise à la terre,

•Les outils à double isolation sont équipés d’une fiche polarisée (une des lames est plus large que l’autre), qui ne peut se brancher que d’une seule façon dans une prise polarisée Ne modifiez pas la fiche de l’outil. Les modèles DW217, DW221, DW222, DW223, DW226, DW231, DW235, DW236, DW245, et DW246 sont equipés d´une fishe polariseé. La double isolation ![]() élimine le besoin d’un cordon d’alimentation à trois fils avec mise à la terre ainsi que d’une prise de courant mise à la terre. Les modèles DW217, DW221, DW222, DW223,

élimine le besoin d’un cordon d’alimentation à trois fils avec mise à la terre ainsi que d’une prise de courant mise à la terre. Les modèles DW217, DW221, DW222, DW223,

•Évitez tout contact corporel avec des surfaces mises à la terre (tuyauterie, radiateurs, cuisinières, réfrigérateurs, etc.). Le risque de choc électrique est plus grand si votre corps est en contact avec la terre.

•N’exposez pas les outils électriques à la pluie ou à l’eau. La présence d’eau dans un outil électrique augmente le risque de choc électrique.

•Ne maltraitez pas le cordon. Ne transportez pas l’outil par son cordon et ne débranchez pas la fiche en tirant sur le cordon. N’exposez pas le cordon à la chaleur, à des huiles, à des arêtes vives ou à des pièces en mouvement. Remplacez immédiatement un cordon endommagé. Un cordon endommagé augmente le risque de choc électrique.

•Lorsque vous utilisez un outil électrique à l’extérieur, employez un prolongateur pour l’extérieur marqué

Calibre minimal des cordons de rallonge

| Tension |

| Longueur totale du cordon en pieds | ||||

| 120 V |

| |||||

| 240 V |

| |||||

| Intensité (A) |

| Calibre moyen de fil (AWG) | ||||

| Au |

| Au |

| |||

| moins | plus |

|

|

|

| |

| 0 | - | 6 | 18 | 16 | 16 | 14 |

6 | - | 10 | 18 | 16 | 14 | 12 | |

SÉCURITÉ DES PERSONNES

•Restez alerte,

•