8. | Measure to the center of the circle you wish to cut and adjust the length of the guide to that |

| radius. |

9. | Tighten the knob (O) holding the centerpoint in position. |

10. | Drill a 5/32" hole in the material to be cut at the center of the radius. |

11. | Plug in the tool, start the motor and allow the tool to spin up to speed. |

12. | Position the center point into the hole and plunge the cutter into the material. |

13. | With firm pressure, hold the center point in place and move the cutter counterclockwise |

| around to the finish. |

CAUTION: At the finish of the circle, the material may drop out. Hold the tool with both hands to maintain control.

CAUTION: At the finish of the circle, the material may drop out. Hold the tool with both hands to maintain control.

14.To remove the circle cutter, loosen knob (H) until the tool can come off the locator and slip out of the strap (J).

15.Reassemble the depth guide and reattach.

Operation

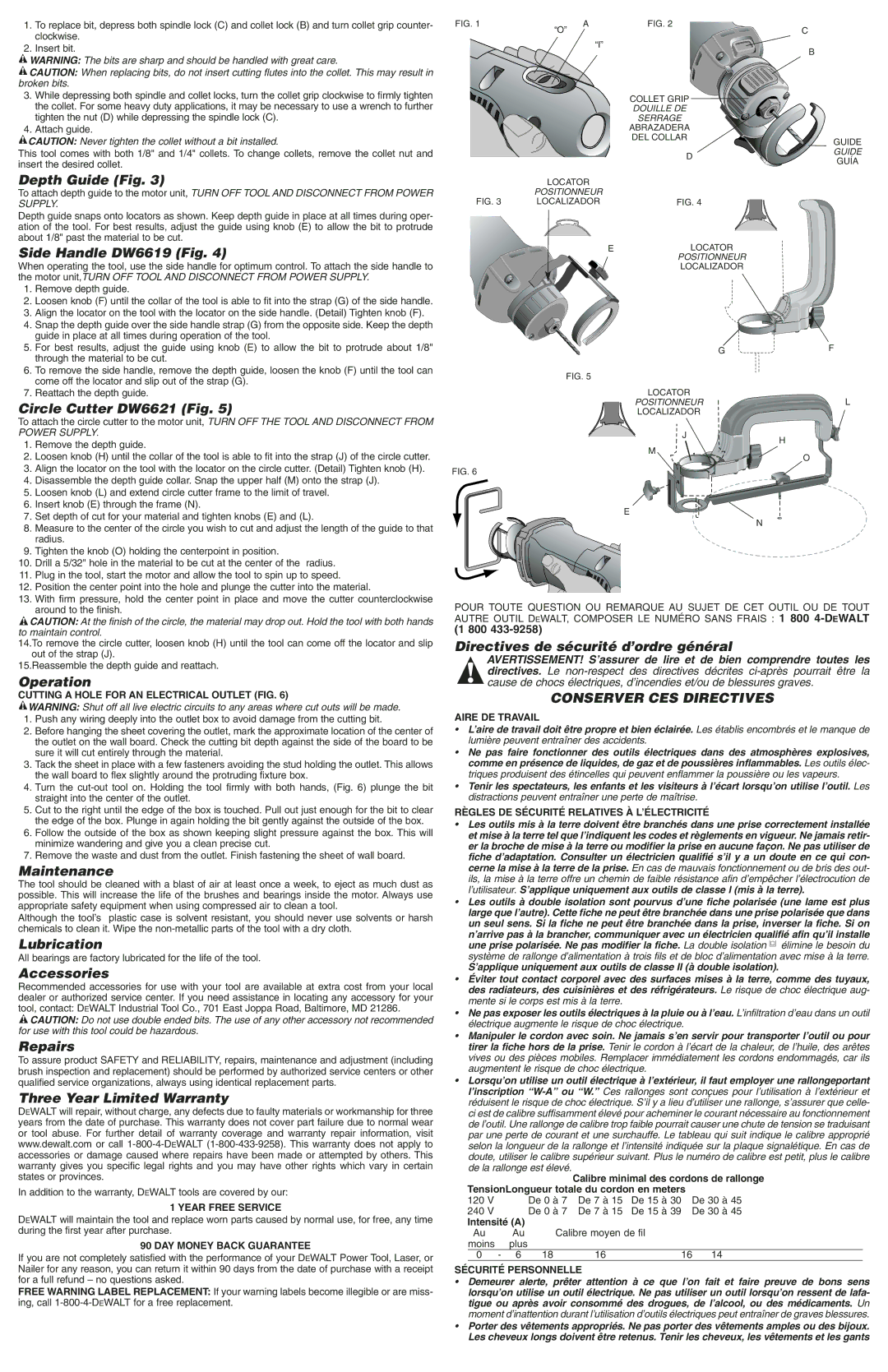

CUTTING A HOLE FOR AN ELECTRICAL OUTLET (FIG. 6)

WARNING: Shut off all live electric circuits to any areas where cut outs will be made.

WARNING: Shut off all live electric circuits to any areas where cut outs will be made.

1.Push any wiring deeply into the outlet box to avoid damage from the cutting bit.

2.Before hanging the sheet covering the outlet, mark the approximate location of the center of the outlet on the wall board. Check the cutting bit depth against the side of the board to be sure it will cut entirely through the material.

3.Tack the sheet in place with a few fasteners avoiding the stud holding the outlet. This allows the wall board to flex slightly around the protruding fixture box.

4.Turn the cut-out tool on. Holding the tool firmly with both hands, (Fig. 6) plunge the bit straight into the center of the outlet.

5.Cut to the right until the edge of the box is touched. Pull out just enough for the bit to clear the edge of the box. Plunge in again holding the bit gently against the outside of the box.

6.Follow the outside of the box as shown keeping slight pressure against the box. This will minimize wandering and give you a clean precise cut.

7.Remove the waste and dust from the outlet. Finish fastening the sheet of wall board.

Maintenance

The tool should be cleaned with a blast of air at least once a week, to eject as much dust as possible. This will increase the life of the brushes and bearings inside the motor. Always use appropriate safety equipment when using compressed air to clean a tool.

Although the tool’s plastic case is solvent resistant, you should never use solvents or harsh chemicals to clean it. Wipe the non-metallic parts of the tool with a dry cloth.

Lubrication

All bearings are factory lubricated for the life of the tool.

Accessories

Recommended accessories for use with your tool are available at extra cost from your local dealer or authorized service center. If you need assistance in locating any accessory for your tool, contact: DEWALT Industrial Tool Co., 701 East Joppa Road, Baltimore, MD 21286.

CAUTION: Do not use double ended bits. The use of any other accessory not recommended for use with this tool could be hazardous.

CAUTION: Do not use double ended bits. The use of any other accessory not recommended for use with this tool could be hazardous.

Repairs

To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush inspection and replacement) should be performed by authorized service centers or other qualified service organizations, always using identical replacement parts.

Three Year Limited Warranty

DEWALT will repair, without charge, any defects due to faulty materials or workmanship for three years from the date of purchase. This warranty does not cover part failure due to normal wear or tool abuse. For further detail of warranty coverage and warranty repair information, visit www.dewalt.com or call 1-800-4-DEWALT (1-800-433-9258). This warranty does not apply to accessories or damage caused where repairs have been made or attempted by others. This warranty gives you specific legal rights and you may have other rights which vary in certain states or provinces.

In addition to the warranty, DEWALT tools are covered by our:

1 YEAR FREE SERVICE

DEWALT will maintain the tool and replace worn parts caused by normal use, for free, any time during the first year after purchase.

90 DAY MONEY BACK GUARANTEE

If you are not completely satisfied with the performance of your DEWALT Power Tool, Laser, or Nailer for any reason, you can return it within 90 days from the date of purchase with a receipt for a full refund – no questions asked.

FREE WARNING LABEL REPLACEMENT: If your warning labels become illegible or are miss- ing, call 1-800-4-DEWALT for a free replacement.

N

POUR TOUTE QUESTION OU REMARQUE AU SUJET DE CET OUTIL OU DE TOUT AUTRE OUTIL DEWALT, COMPOSER LE NUMÉRO SANS FRAIS : 1 800 4-DEWALT

(1 800 433-9258)

Directives de sécurité d’ordre général

AVERTISSEMENT! S’assurer de lire et de bien comprendre toutes les directives. Le non-respect des directives décrites ci-après pourrait être la cause de chocs électriques, d’incendies et/ou de blessures graves.

CONSERVER CES DIRECTIVES

AIRE DE TRAVAIL

•L’aire de travail doit être propre et bien éclairée. Les établis encombrés et le manque de lumière peuvent entraîner des accidents.

•Ne pas faire fonctionner des outils électriques dans des atmosphères explosives, comme en présence de liquides, de gaz et de poussières inflammables. Les outils élec- triques produisent des étincelles qui peuvent enflammer la poussière ou les vapeurs.

•Tenir les spectateurs, les enfants et les visiteurs à l’écart lorsqu’on utilise l’outil. Les distractions peuvent entraîner une perte de maîtrise.

RÈGLES DE SÉCURITÉ RELATIVES À L’ÉLECTRICITÉ

•Les outils mis à la terre doivent être branchés dans une prise correctement installée et mise à la terre tel que l’indiquent les codes et règlements en vigueur. Ne jamais retir- er la broche de mise à la terre ou modifier la prise en aucune façon. Ne pas utiliser de fiche d’adaptation. Consulter un électricien qualifié s’il y a un doute en ce qui con- cerne la mise à la terre de la prise. En cas de mauvais fonctionnement ou de bris des out- ils, la mise à la terre offre un chemin de faible résistance afin d’empêcher l’électrocution de l’utilisateur. S’applique uniquement aux outils de classe I (mis à la terre).

•Les outils à double isolation sont pourvus d’une fiche polarisée (une lame est plus large que l’autre). Cette fiche ne peut être branchée dans une prise polarisée que dans un seul sens. Si la fiche ne peut être branchée dans la prise, inverser la fiche. Si on n’arrive pas à la brancher, communiquer avec un électricien qualifié afin qu’il installe une prise polarisée. Ne pas modifier la fiche. La double isolation  élimine le besoin du système de rallonge d’alimentation à trois fils et de bloc d’alimentation avec mise à la terre.

élimine le besoin du système de rallonge d’alimentation à trois fils et de bloc d’alimentation avec mise à la terre.

S’applique uniquement aux outils de classe II (à double isolation).

•Éviter tout contact corporel avec des surfaces mises à la terre, comme des tuyaux, des radiateurs, des cuisinières et des réfrigérateurs. Le risque de choc électrique aug- mente si le corps est mis à la terre.

•Ne pas exposer les outils électriques à la pluie ou à l’eau. L’infiltration d’eau dans un outil électrique augmente le risque de choc électrique.

•Manipuler le cordon avec soin. Ne jamais s’en servir pour transporter l’outil ou pour tirer la fiche hors de la prise. Tenir le cordon à l’écart de la chaleur, de l’huile, des arêtes vives ou des pièces mobiles. Remplacer immédiatement les cordons endommagés, car ils augmentent le risque de choc électrique.

•Lorsqu’on utilise un outil électrique à l’extérieur, il faut employer une rallongeportant l’inscription “W-A” ou “W.” Ces rallonges sont conçues pour l’utilisation à l’extérieur et réduisent le risque de choc électrique. S’il y a lieu d’utiliser une rallonge, s’assurer que celle- ci est de calibre suffisamment élevé pour acheminer le courant nécessaire au fonctionnement de l’outil. Une rallonge de calibre trop faible pourrait causer une chute de tension se traduisant par une perte de courant et une surchauffe. Le tableau qui suit indique le calibre approprié selon la longueur de la rallonge et l’intensité indiquée sur la plaque signalétique. En cas de doute, utiliser le calibre supérieur suivant. Plus le numéro de calibre est petit, plus le calibre

de la rallonge est élevé.

| | | | Calibre minimal des cordons de rallonge |

TensionLongueur totale du cordon en meters | |

120 V | | De 0 à 7 | De 7 à 15 | De 15 à 30 | De 30 à 45 |

240 V | | De 0 à 7 | De 7 à 15 | De 15 à 39 | De 30 à 45 |

Intensité (A) | | | | |

| Au | Au | Calibre moyen de fil | |

moins | plus | | | | |

| 0 - | 6 | 18 | 16 | 16 | 14 |

SÉCURITÉ PERSONNELLE

•Demeurer alerte, prêter attention à ce que l’on fait et faire preuve de bons sens lorsqu’on utilise un outil électrique. Ne pas utiliser un outil lorsqu’on ressent de lafa- tigue ou après avoir consommé des drogues, de l’alcool, ou des médicaments. Un moment d’inattention durant l’utilisation d’outils électriques peut entraîner de graves blessures.