English

![]() WARNING: A workpiece that is clamped, balanced and secure before a cut may become unbalanced after a cut is completed. An unbalanced load may tip the saw or anything the saw is attached to, such as a table or workbench. When making a cut that may become unbalanced, properly support the workpiece and ensure the saw is firmly bolted to a stable surface. Personal injury may occur.

WARNING: A workpiece that is clamped, balanced and secure before a cut may become unbalanced after a cut is completed. An unbalanced load may tip the saw or anything the saw is attached to, such as a table or workbench. When making a cut that may become unbalanced, properly support the workpiece and ensure the saw is firmly bolted to a stable surface. Personal injury may occur.

![]() WARNING: The clamp foot must remain clamped above the base of the saw whenever the clamp is used. Always clamp the workpiece to the base of the

WARNING: The clamp foot must remain clamped above the base of the saw whenever the clamp is used. Always clamp the workpiece to the base of the

![]() CAUTION: Always use a work clamp to maintain control and reduce the risk of workpiece damage and personal injury.

CAUTION: Always use a work clamp to maintain control and reduce the risk of workpiece damage and personal injury.

If you cannot secure the workpiece on the table and against the fence by hand, (irregular shape, etc.) or your hand would be less than 6" (152 mm) from the blade, a clamp or other fixture should be used.

For best results use the DW7082 clamp made for use with your saw. It is available through your local retailer or DEWALT service center at extra cost.

Other aids such as spring clamps, bar clamps or

TO INSTALL CLAMP (SOLD SEPARATELY)

1.Insert it into the hole behind the fence. The clamp should be facing toward the back of the miter saw. The groove on the clamp rod should be fully inserted into the base. Ensure this groove is fully inserted into the base of the miter saw. If the groove is visible, the clamp will not be secure.

2.Rotate the clamp 180º toward the front of the miter saw.

3.Loosen the knob to adjust the clamp up or down, then use the fine adjust knob to firmly clamp the workpiece.

NOTE: Place the clamp on the opposite side of the base when beveling. ALWAYS MAKE DRY RUNS (UNPOWERED) BEFORE FINISH CUTS TO CHECK THE PATH OF THE BLADE. ENSURE THE CLAMP DOES NOT INTERFERE WITH THE ACTION OF THE SAW OR GUARDS.

![]() WARNING: A workpiece that is clamped, balanced and secure before a cut may become unbalanced after a cut is completed. An unbalanced load may tip the saw or anything the saw is attached to, such as a table or workbench. When making a cut that may become unbalanced, properly support the workpiece and ensure the saw is firmly bolted to a stable surface.

WARNING: A workpiece that is clamped, balanced and secure before a cut may become unbalanced after a cut is completed. An unbalanced load may tip the saw or anything the saw is attached to, such as a table or workbench. When making a cut that may become unbalanced, properly support the workpiece and ensure the saw is firmly bolted to a stable surface.

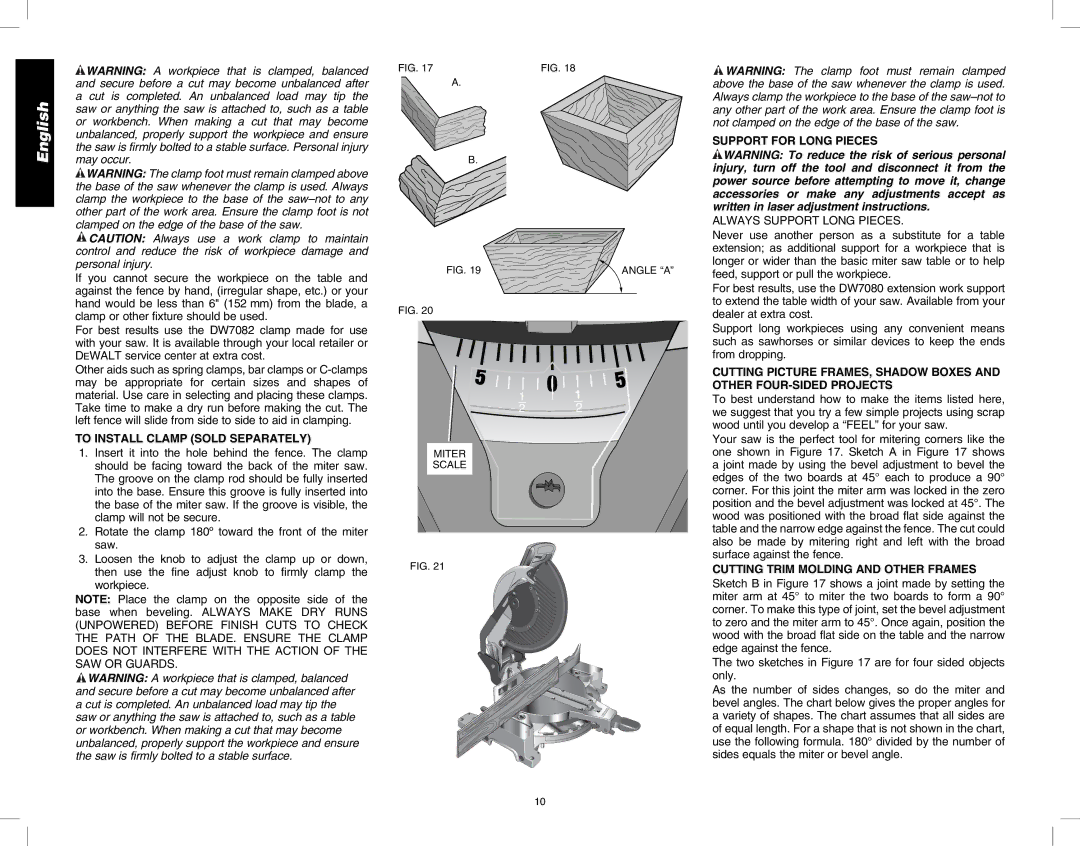

FIG. 17

A.

B.

FIG. 19

FIG. 20

MITER

SCALE

FIG. 21

FIG. 18 | WARNING: The clamp foot must remain clamped |

| above the base of the saw whenever the clamp is used. |

| Always clamp the workpiece to the base of the |

| any other part of the work area. Ensure the clamp foot is |

| not clamped on the edge of the base of the saw. |

| SUPPORT FOR LONG PIECES |

| WARNING: To reduce the risk of serious personal |

| injury, turn off the tool and disconnect it from the |

| power source before attempting to move it, change |

| accessories or make any adjustments accept as |

| written in laser adjustment instructions. |

| ALWAYS SUPPORT LONG PIECES. |

| Never use another person as a substitute for a table |

| extension; as additional support for a workpiece that is |

ANGLE “A” | longer or wider than the basic miter saw table or to help |

feed, support or pull the workpiece. | |

| For best results, use the DW7080 extension work support |

| to extend the table width of your saw. Available from your |

| dealer at extra cost. |

| Support long workpieces using any convenient means |

| such as sawhorses or similar devices to keep the ends |

| from dropping. |

| CUTTING PICTURE FRAMES, SHADOW BOXES AND |

| OTHER |

| To best understand how to make the items listed here, |

| we suggest that you try a few simple projects using scrap |

| wood until you develop a “FEEL” for your saw. |

| Your saw is the perfect tool for mitering corners like the |

| one shown in Figure 17. Sketch A in Figure 17 shows |

| a joint made by using the bevel adjustment to bevel the |

| edges of the two boards at 45° each to produce a 90° |

| corner. For this joint the miter arm was locked in the zero |

| position and the bevel adjustment was locked at 45°. The |

| wood was positioned with the broad flat side against the |

| table and the narrow edge against the fence. The cut could |

| also be made by mitering right and left with the broad |

| surface against the fence. |

| CUTTING TRIM MOLDING AND OTHER FRAMES |

| Sketch B in Figure 17 shows a joint made by setting the |

| miter arm at 45° to miter the two boards to form a 90° |

| corner. To make this type of joint, set the bevel adjustment |

| to zero and the miter arm to 45°. Once again, position the |

| wood with the broad flat side on the table and the narrow |

| edge against the fence. |

| The two sketches in Figure 17 are for four sided objects |

| only. |

| As the number of sides changes, so do the miter and |

| bevel angles. The chart below gives the proper angles for |

| a variety of shapes. The chart assumes that all sides are |

| of equal length. For a shape that is not shown in the chart, |

| use the following formula. 180° divided by the number of |

| sides equals the miter or bevel angle. |

10