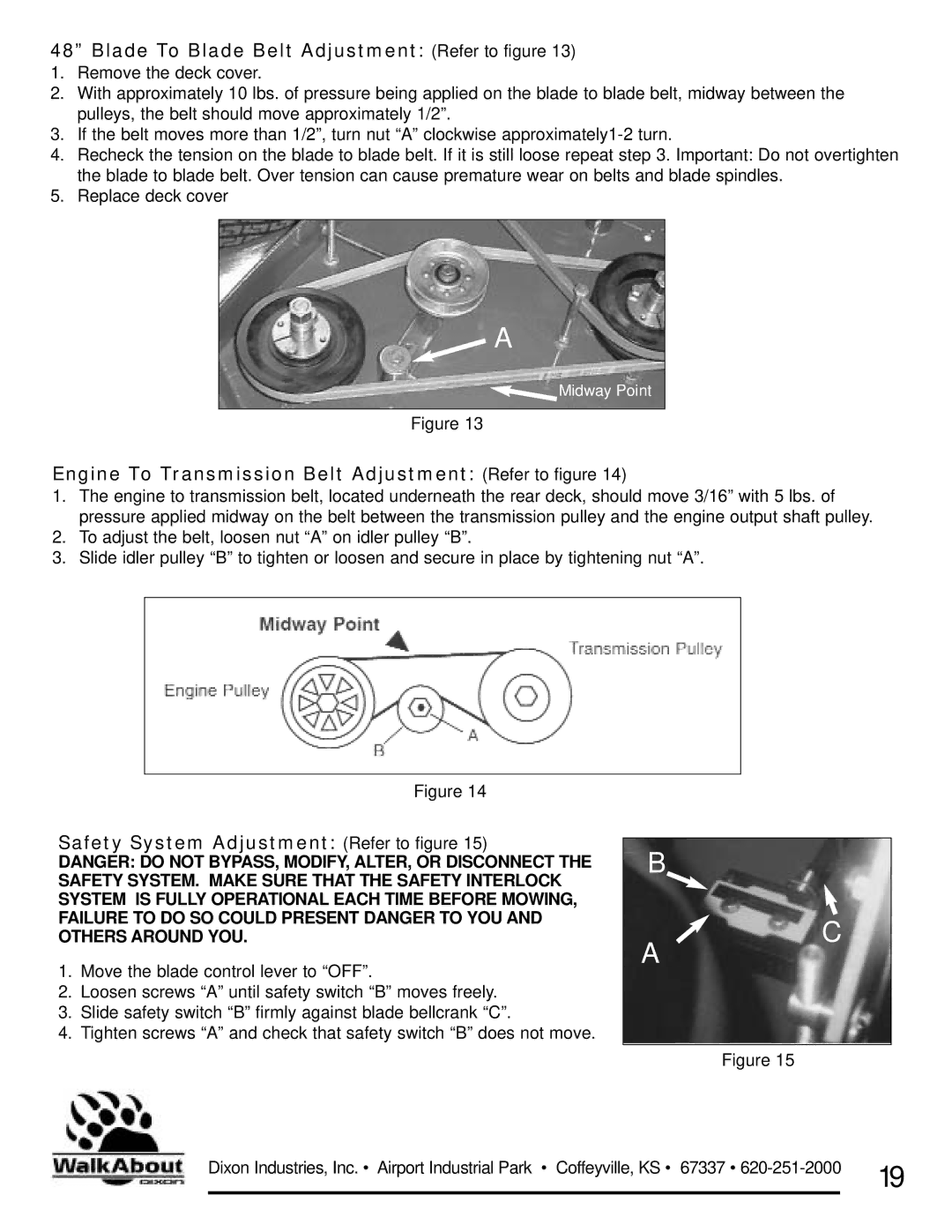

48” Blade To Blade Belt Adjustment: (Refer to figure 13)

1.Remove the deck cover.

2.With approximately 10 lbs. of pressure being applied on the blade to blade belt, midway between the pulleys, the belt should move approximately 1/2”.

3.If the belt moves more than 1/2”, turn nut “A” clockwise

4.Recheck the tension on the blade to blade belt. If it is still loose repeat step 3. Important: Do not overtighten the blade to blade belt. Over tension can cause premature wear on belts and blade spindles.

5.Replace deck cover

A

Midway Point

Figure 13

Engine To Transmission Belt Adjustment: (Refer to figure 14)

1.The engine to transmission belt, located underneath the rear deck, should move 3/16” with 5 lbs. of pressure applied midway on the belt between the transmission pulley and the engine output shaft pulley.

2.To adjust the belt, loosen nut “A” on idler pulley “B”.

3.Slide idler pulley “B” to tighten or loosen and secure in place by tightening nut “A”.

Figure 14

Safety System Adjustment: (Refer to figure 15)

DANGER: DO NOT BYPASS, MODIFY, ALTER, OR DISCONNECT THE SAFETY SYSTEM. MAKE SURE THAT THE SAFETY INTERLOCK SYSTEM IS FULLY OPERATIONAL EACH TIME BEFORE MOWING, FAILURE TO DO SO COULD PRESENT DANGER TO YOU AND

B

OTHERS AROUND YOU.

1.Move the blade control lever to “OFF”.

2.Loosen screws “A” until safety switch “B” moves freely.

3.Slide safety switch “B” firmly against blade bellcrank “C”.

4.Tighten screws “A” and check that safety switch “B” does not move.

A

C

Figure 15

Dixon Industries, Inc. • Airport Industrial Park • Coffeyville, KS • 67337 • | 19 | |

| ||

|

|

|