Caster Wheels

Check every 200 hours. Lift front of unit off of ground so caster wheels can rotate freely. Tighten caster bolt then back off ½ turn. Check that wheel rotates freely. If wheel does not rotate freely back the caster bolt off in

¼turn increments until wheel rotates freely.

IMPORTANT INFORMATION

DO NOT add any type of tire liner or foam fill material to the tires. Excessive loads created by foam filled tires will cause premature failures.

Only use O.E.M. specified tires.

Foam filled tires or solid tires will void the warranty.

Hardware

Check daily. Inspect the entire machine for loose or missing hardware.

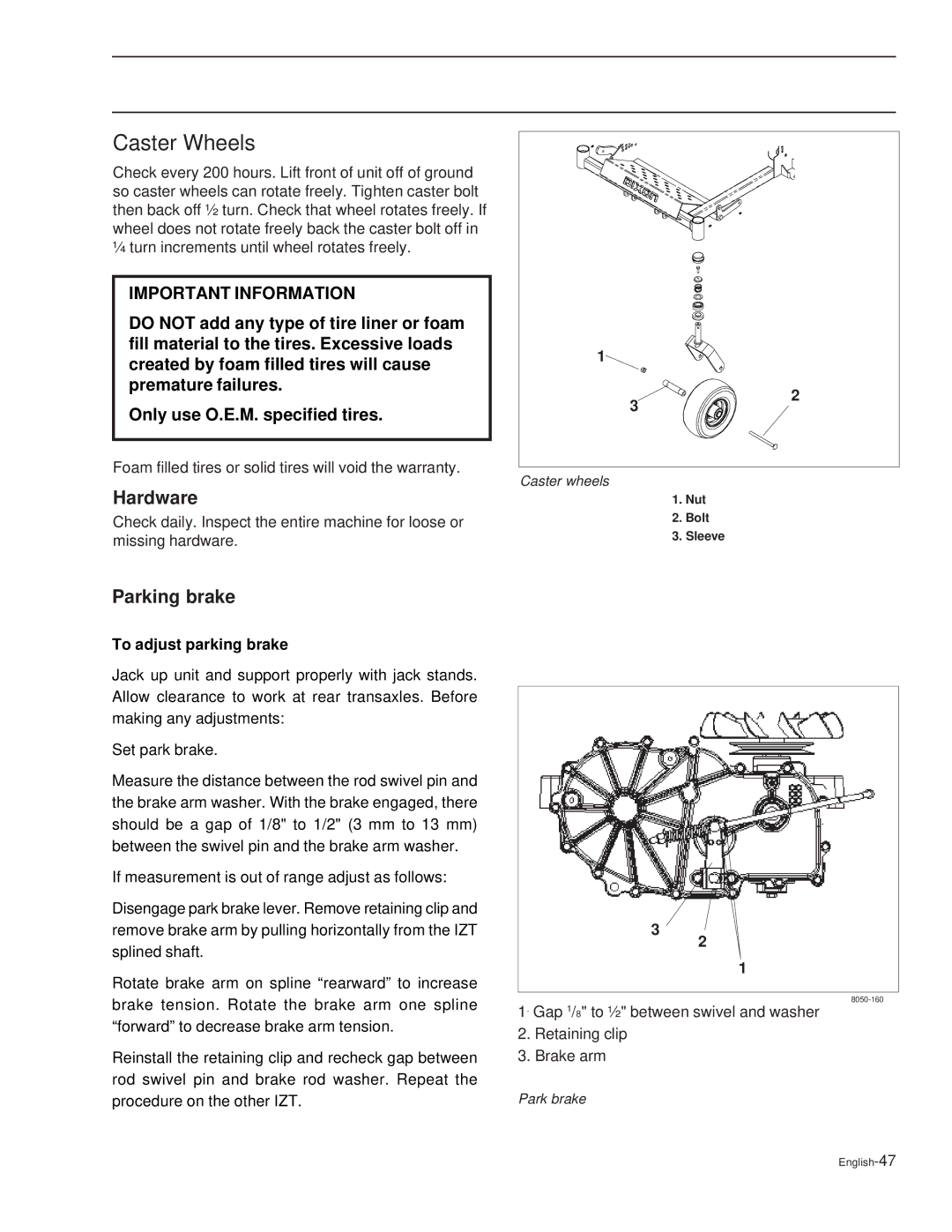

1 |

|

3 | 2 |

|

Caster wheels

1.Nut

2.Bolt

3.Sleeve

Parking brake

To adjust parking brake

Jack up unit and support properly with jack stands. Allow clearance to work at rear transaxles. Before making any adjustments:

Set park brake.

Measure the distance between the rod swivel pin and the brake arm washer. With the brake engaged, there should be a gap of 1/8" to 1/2" (3 mm to 13 mm) between the swivel pin and the brake arm washer.

If measurement is out of range adjust as follows:

Disengage park brake lever. Remove retaining clip and remove brake arm by pulling horizontally from the IZT splined shaft.

Rotate brake arm on spline “rearward” to increase brake tension. Rotate the brake arm one spline “forward” to decrease brake arm tension.

Reinstall the retaining clip and recheck gap between rod swivel pin and brake rod washer. Repeat the procedure on the other IZT.

3

2

1

1. Gap 1/8" to ½" between swivel and washer

2.Retaining clip

3.Brake arm

Park brake