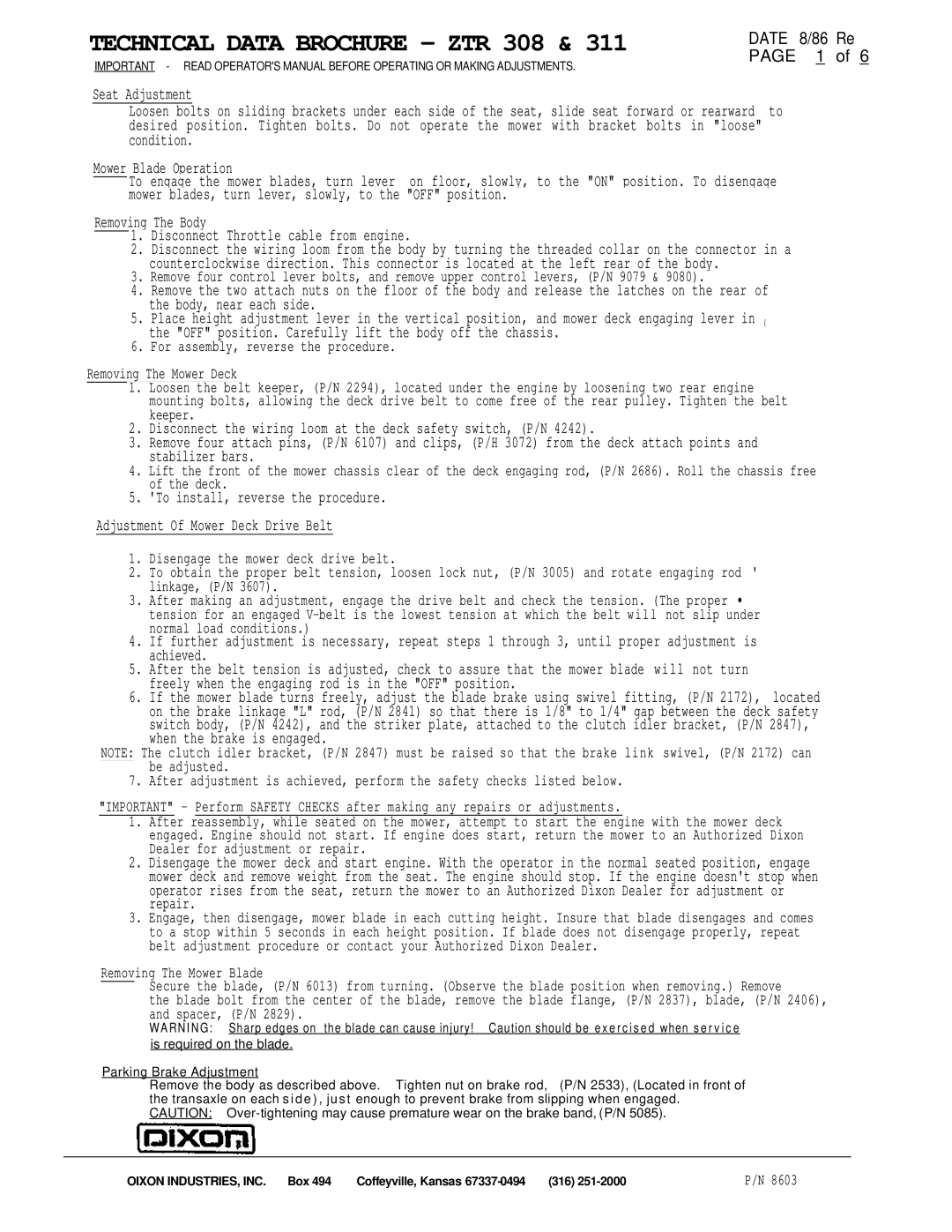

ZTR 308, ZTR 311 specifications

Dixon ZTR 308 and ZTR 311 are renowned models in the commercial-grade zero-turn mower category, designed for efficiency and performance in various mowing applications. Both models showcase Dixon's commitment to delivering robust, user-friendly equipment for professional landscapers and serious homeowners alike.The Dixon ZTR 308 comes equipped with a powerful engine, ensuring reliable performance across different terrains. Its efficient cutting deck, typically available in widths of up to 48 inches, allows for fast mowing while maintaining a clean, precise cut. The ZTR 308 features a dual hydrostatic transmission, providing exceptional maneuverability and speed. Operators appreciate the ease of control, which allows for navigating around obstacles without compromising time or effort.

On the other hand, the Dixon ZTR 311 steps up the game with slightly enhanced specifications. This model combines a robust engine with an improved cutting deck, often available in widths up to 54 inches. The ZTR 311’s hydrostatic transmission allows for seamless speed adjustments, a beneficial feature when tackling various lawn conditions. The responsiveness of the controls makes this model particularly favored for those managing larger properties or commercial lawns.

Both the ZTR 308 and ZTR 311 incorporate user-centric designs, including adjustable high-back seats that provide comfort during extended use. The ergonomic design of the controls enhances operator ease, minimizing fatigue during long working hours. Both models also prioritize safety, featuring automatic brakes that engage when the operator leaves the seat, ensuring protection against accidental operation.

Dixon’s commitment to durability is evident in the construction of both mowers; features such as a heavy-duty frame and reinforced cutting decks are standard. Furthermore, these models utilize advanced technology to enhance mowing efficiency. The innovative blade engagement system provides a quick and responsive start-up, while the maintenance-friendly design reduces service time, allowing more time for mowing.

In conclusion, the Dixon ZTR 308 and ZTR 311 are exemplary models that combine power, precision, and ease of use. With advanced features designed for efficiency and a focus on user comfort, both models represent a solid investment for professionals and enthusiasts who demand high performance from their mowing equipment. Whether tackling residential lawns or larger commercial spaces, these zero-turn mowers are equipped to deliver exceptional results, making them a preferred choice in the industry.