DM 2610921728

Operation (continued)

12.Mark the hole locations on the work- piece and center punch at these loca- tions. Center punching will prevent walk- ing of the drill point and ensure proper hole location. The benefits of center punching are less drill breakage and better hole size tolerance.

13.Secure the workpiece to the base before drilling. This will keep the workpiece from climbing the drill bit or spinning. The benefit is safety and better quality work. Hold down clamps (not included) are very good for holding workpieces, or use a small utility vise for holding the workpiece when drilling (Figure 6).

14.Loosen the Height Adjustment Lock lever 1/2 turn and move the press on the tube until drill bit tip is near the work- piece. (A maximum of 1/4" between drill bit tip and workpiece is recommended.) Retighten lock lever.

15.Grasp the Press Handle and pull down to drill hole.

Helpful hints

When drilling round pieces, use a “V” block or vise. To drill a hole in the center of a round piece, a center punch mark is necessary (Figure 7). Use center punch to make center punch mark (not included).

Avoid force feeding to such an extent that the motor speed is noticeably reduced. Also, feed carefully when approaching point of breakthrough. This will avoid making ragged breakthrough edges.

For accurate drilling, lower the tool to a loca- tion where the end of the drill bit is within 1/4" of the workpiece before advancing the han- dle for feeding the drill. Using minimum stroke and center punching at the location to be drilled will ensure accurate drilling.

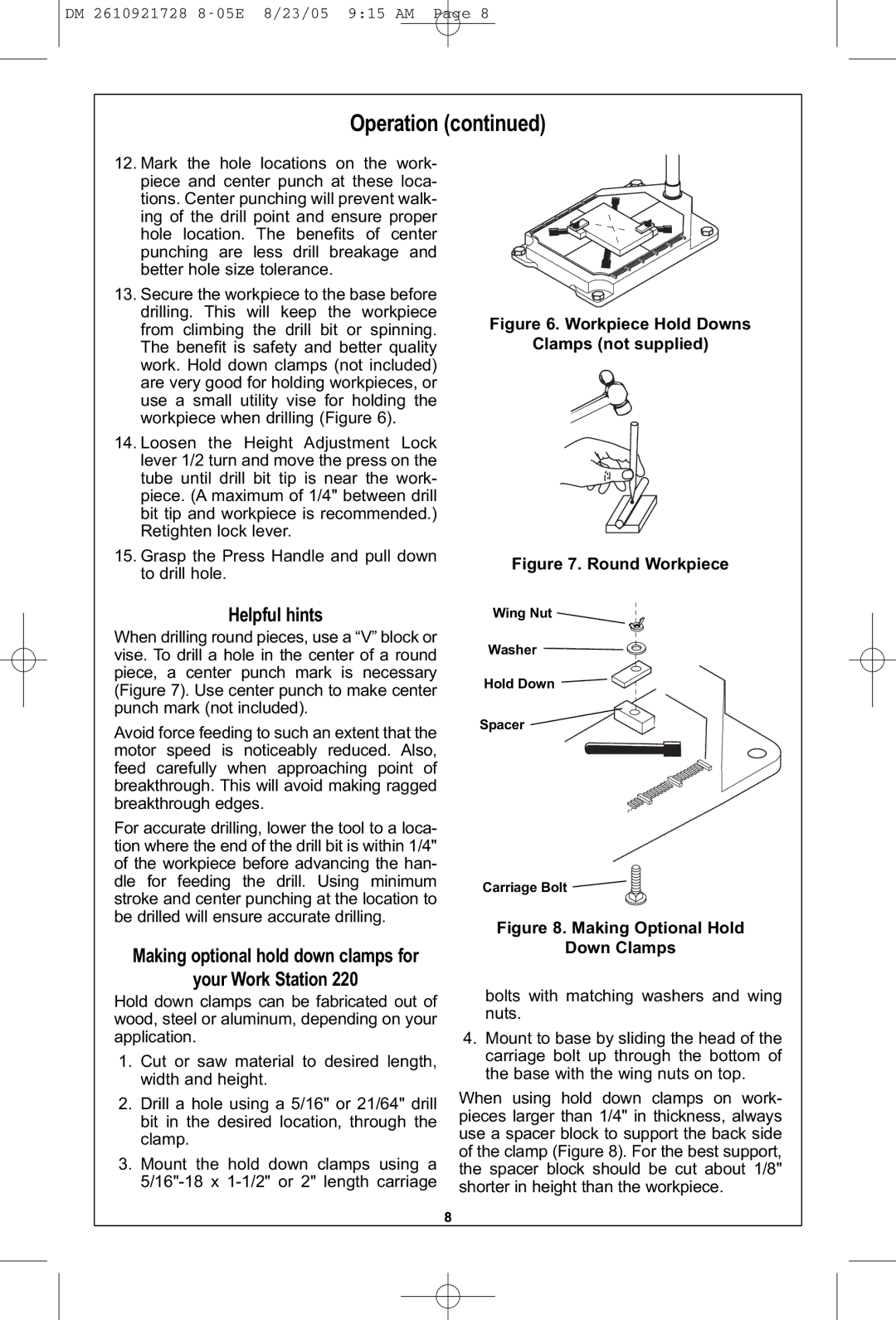

Making optional hold down clamps for

your Work Station 220

Hold down clamps can be fabricated out of wood, steel or aluminum, depending on your application.

1. Cut or saw material to desired length, width and height.

2. Drill a hole using a 5/16" or 21/64" drill bit in the desired location, through the clamp.

3. Mount the hold down clamps using a

Figure 6. Workpiece Hold Downs

Clamps (not supplied)

Figure 7. Round Workpiece

Wing Nut

Washer ![]()

![]()

Hold Down ![]()

![]()

Spacer ![]()

![]()

![]()

Carriage Bolt ![]()

![]()

Figure 8. Making Optional Hold

Down Clamps

bolts with matching washers and wing nuts.

4. Mount to base by sliding the head of the carriage bolt up through the bottom of the base with the wing nuts on top.

When using hold down clamps on work- pieces larger than 1/4" in thickness, always use a spacer block to support the back side of the clamp (Figure 8). For the best support, the spacer block should be cut about 1/8" shorter in height than the workpiece.

8