DM 2610920458

Tool Lubrication

Periodic cleaning and lubrication of guide posts will keep plunge action smooth.

Depress and lock plunge router and evenly apply a light lubricant (i.e. petroleum jelly, cooking oil) to upper portion of guide posts.

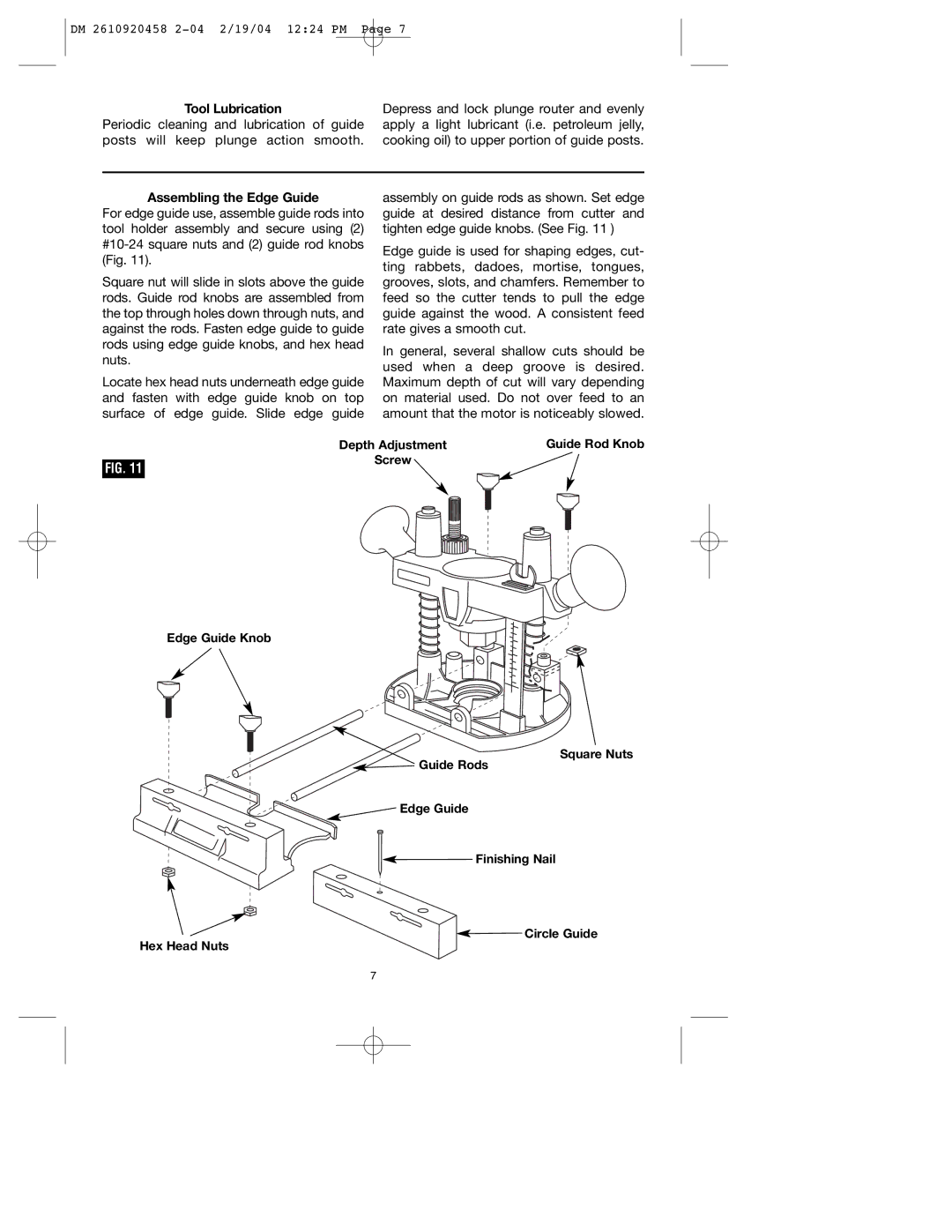

Assembling the Edge Guide

For edge guide use, assemble guide rods into tool holder assembly and secure using (2)

Square nut will slide in slots above the guide rods. Guide rod knobs are assembled from the top through holes down through nuts, and against the rods. Fasten edge guide to guide rods using edge guide knobs, and hex head nuts.

Locate hex head nuts underneath edge guide and fasten with edge guide knob on top surface of edge guide. Slide edge guide

assembly on guide rods as shown. Set edge guide at desired distance from cutter and tighten edge guide knobs. (See Fig. 11 )

Edge guide is used for shaping edges, cut- ting rabbets, dadoes, mortise, tongues, grooves, slots, and chamfers. Remember to feed so the cutter tends to pull the edge guide against the wood. A consistent feed rate gives a smooth cut.

In general, several shallow cuts should be used when a deep groove is desired. Maximum depth of cut will vary depending on material used. Do not over feed to an amount that the motor is noticeably slowed.

| Depth Adjustment | Guide Rod Knob |

FIG. 11 | Screw |

|

|

|

Edge Guide Knob

Square Nuts

![]() Guide Rods

Guide Rods

![]() Edge Guide

Edge Guide

![]() Finishing Nail

Finishing Nail

![]()

![]() Circle Guide Hex Head Nuts

Circle Guide Hex Head Nuts

7