DM 2610922740

ASSEMBLY (CONTINUED)

Installing Blade

! WARNING Unplug tool from power source before changing

blade or making any adjustments.

1. Insert the blade fully into the saw open- ing until it bottoms in the tool.

2. Secure the blade in the saw using the Allen wrench to tighten the setscrew.

NOTE: Blade can be mounted with teeth fac- ing either direction.

! WARNING Make sure front end of blade extends through the footplate for the entire stroke length. Do

not use specialty blades that are very short or those with a significant cant. Blade must not contact footplate. A blade which is too short or canted, could jam inside the footplate and snap.

OPERATION

! WARNING When holding tool, do not cover the air vents with your hand. Blocking the air vents could

cause the motor to overheat. Operating Speeds

The speed of your saw is variable from 550 - 3900 SPM (strokes per minute).

Footplate

The footplate tilts in order to keep as much of the surface in contact with the work surface. Keep the saw footplate firmly against the work to minimize counterforce (jumping) and vibration.

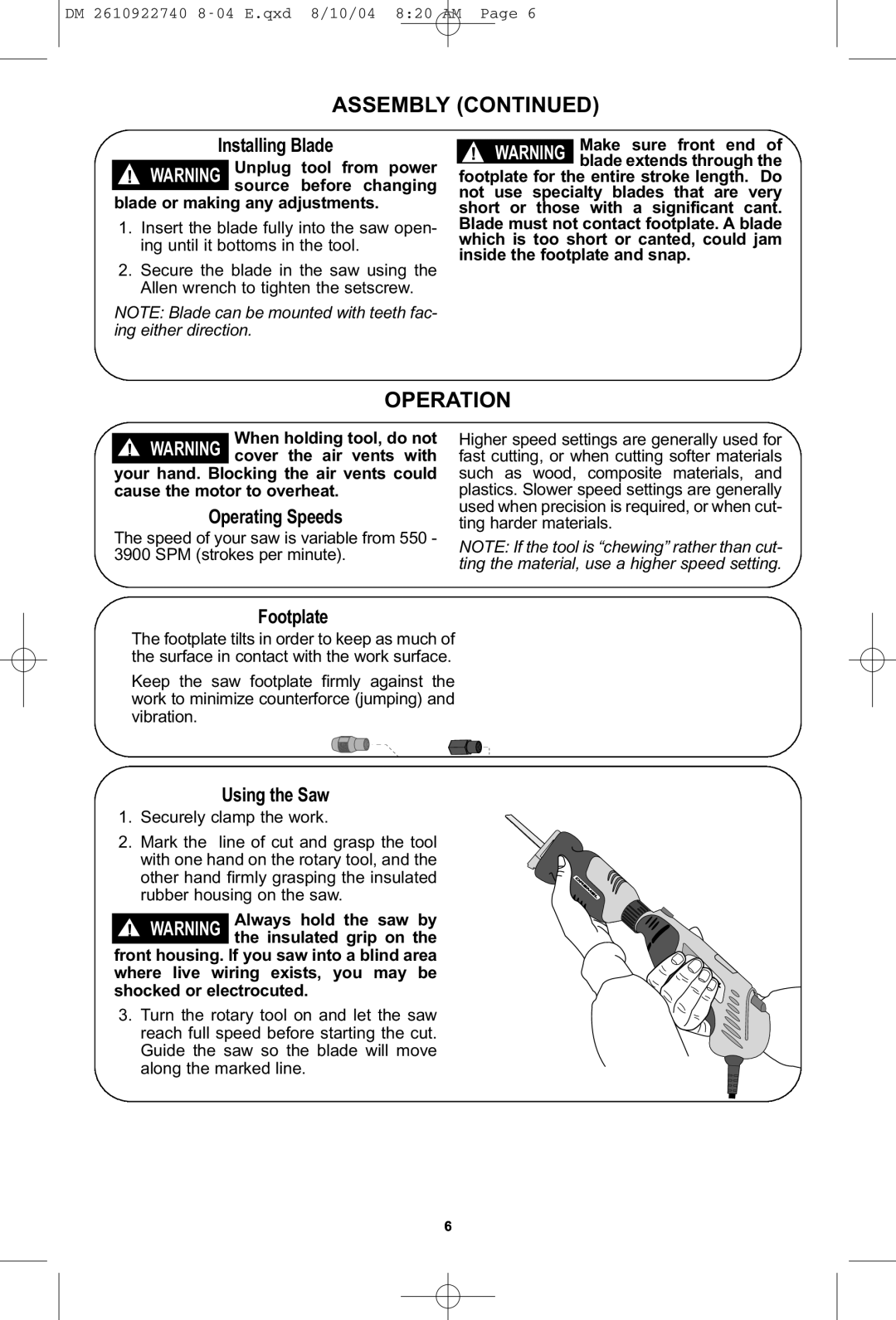

Using the Saw 1. Securely clamp the work.

2. Mark the line of cut and grasp the tool with one hand on the rotary tool, and the other hand firmly grasping the insulated rubber housing on the saw.

! WARNING Always hold the saw by the insulated grip on the front housing. If you saw into a blind area

where live wiring exists, you may be shocked or electrocuted.

3. Turn the rotary tool on and let the saw reach full speed before starting the cut. Guide the saw so the blade will move along the marked line.

Higher speed settings are generally used for fast cutting, or when cutting softer materials such as wood, composite materials, and plastics. Slower speed settings are generally used when precision is required, or when cut- ting harder materials.

NOTE: If the tool is “chewing” rather than cut- ting the material, use a higher speed setting.

6