DM 2610924275

MODEL PL400 PLANER ATTACHMENT (For use with Dremel 400 Series XPR)

ADITAMENTO DE CEPILLADORA MODELO PL400 (Para usarse con la herramienta rotatoria Series 400 XPR de Dremel)

ACCESSOIRE DE RABOTAGE MODÈLE PL400 (À utiliser avec la série Dremel 400 XPR)

![]() Operating/Safety Instructions

Operating/Safety Instructions

![]() Instrucciones de funcionamiento

Instrucciones de funcionamiento

![]() Notice d’utilisation

Notice d’utilisation

!WARNING Read and understand these instructions and the tool manual before using the Planer Attachment.

Wear eye protection.

!Lea y entienda estas instrucciones y el manual de ADVERTENCIA la herramienta antes de utilizar el aditamento de

cepilladora. Lleve protección para los ojos.

Veuillez lire et comprendre ces instructions ! AVERTISSEMENT ainsi que le mode d’emploi de l’outil avant

d’utiliser l’accessoire de rabotage. Portez une protection oculaire.

P.O. Box 1468

Racine, Wisconsin

www.dremel.com

Dremel brand products are manufactured and sold by the Dremel Division of Robert Bosch Tool Corporation

Les produits de marque Dremel sont fabriqués et commercialisés par la Division Dremel de Robert Bosch Tool Corporation

Los productos de la marca Dremel son fabricados y vendidos por la

División Dremel de Robert Bosch Tool Corporation

(1)

(2) OFF

(2) OFF

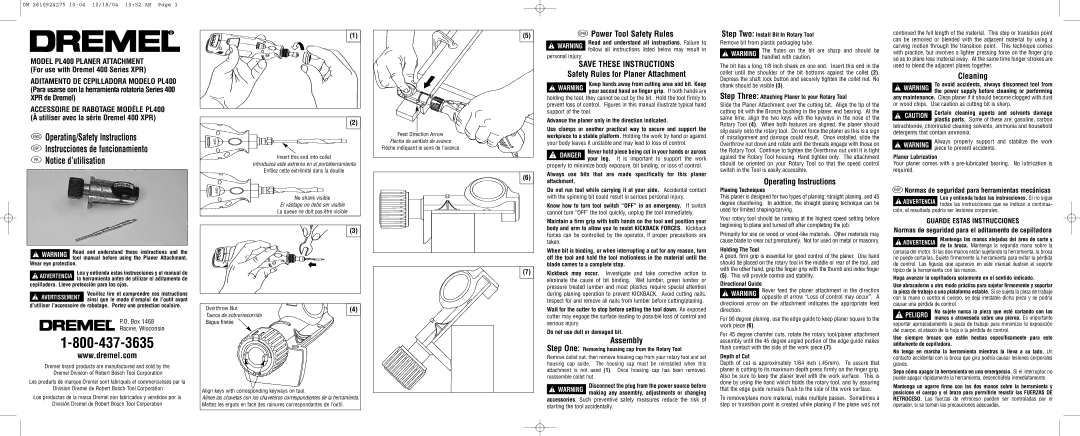

Insert this end into collet

Introduzca este extremo en el portaherramienta

Enfilez cette extrémité dans la douille

OFF ![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() No shank visible

No shank visible

El vástago no debe ser visible La queue ne doit pas être visible

(3)

Overthrow Nut | (4) |

Tuerca de sobrerrecorrido |

|

Bague filetée |

|

Align keys with corresponding keyways on tool.

Alinee las chavetas con los chaveteros correspondientes de la herramienta. Mettez les ergots en face des rainures correspondantes de l’outil.

(5)

Feed Direction Arrow

Flecha de sentido de avance

Flèche indiquant le sens de l’avance

(6) |

(7) |

![]() Power Tool Safety Rules

Power Tool Safety Rules

!WARNING Read and understand all instructions. Failure to follow all instructions listed below may result in

personal injury.

SAVE THESE INSTRUCTIONS

Safety Rules for Planer Attachment

Keep hands away from cutting area and bit. Keep ! WARNING your second hand on finger grip. If both hands are

holding the tool, they cannot be cut by the bit. Hold the tool firmly to prevent loss of control. Figures in this manual illustrate typical hand support of the tool.

Advance the planer only in the direction indicated.

Use clamps or another practical way to secure and support the workpiece to a stable platform. Holding the work by hand or against your body leaves it unstable and may lead to loss of control.

!Never hold piece being cut in your hands or across DANGER your leg. It is important to support the work

properly to minimize body exposure, bit binding, or loss of control.

Always use bits that are made specifically for this planer attachment.

Do not run tool while carrying it at your side. Accidental contact with the spinning bit could result in serious personal injury.

Know how to turn tool switch “OFF” in an emergency. If switch cannot turn “OFF” the tool quickly, unplug the tool immediately.

Maintain a firm grip with both hands on the tool and position your body and arm to allow you to resist KICKBACK FORCES. Kickback forces can be controlled by the operator, if proper precautions are taken.

When bit is binding, or when interrupting a cut for any reason, turn off the tool and hold the tool motionless in the material until the blade comes to a complete stop.

Kickback may occur. Investigate and take corrective action to eliminate the cause of bit binding. Wet lumber, green lumber or pressure treated lumber and most plastics require special attention during planing operation to prevent KICKBACK. Avoid cutting nails. Inspect for and remove all nails from lumber before cutting/planing.

Wait for the cutter to stop before setting the tool down. An exposed cutter may engage the surface leading to possible loss of control and serious injury.

Do not use dull or damaged bit.

Assembly

Step One: Removing housing cap from the Rotary Tool

Remove collet nut, then remove housing cap from your rotary tool and set housing cap aside. The housing cap must be reinstalled when this attachment is not used (1). Once housing cap has been removed, reassemble collet nut.

!Disconnect the plug from the power source before WARNING making any assembly, adjustments or changing

accessories. Such preventive safety measures reduce the risk of starting the tool accidentally.

Step Two: Install Bit In Rotary Tool

Remove bit from plastic packaging tube.

!The flutes on the bit are sharp and should be WARNING handled with caution.

The bit has a long 1/8 inch shank on one end. Insert this end in the collet until the shoulder of the bit bottoms against the collet (2). Depress the shaft lock button and securely tighten the collet nut. No shank should be visible (3).

Step Three: Attaching Planer to your Rotary Tool

Slide the Planer Attachment over the cutting bit. Align the tip of the cutting bit with the Bronze bushing in the planer end bearing. At the same time, align the two keys with the keyways in the nose of the Rotary Tool (4). When both features are aligned, the planer should slip easily onto the rotary tool. Do not force the planer as this is a sign of misalignment and damage could result. Once installed, slide the Overthrow nut down and rotate until the threads engage with those on the Rotary Tool. Continue to tighten the Overthrow nut until it is tight against the Rotary Tool housing. Hand tighten only. The attachment should be oriented on your Rotary Tool so that the speed control switch in the Tool is easily accessible.

Operating Instructions

Planing Techniques

This planer is designed for two types of planing; straight planing, and 45 degree chamfering. In addition, the straight planing technique can be used for limited shaping/carving.

Your rotary tool should be running at the highest speed setting before beginning to plane and turned off after completing the job.

Primarily for use on wood or

Holding The Tool

A good, firm grip is essential for good control of the planer. One hand should be placed on the rotary tool in the middle or rear of the tool, and with the other hand, grip the finger grip with the thumb and index finger

(5). This will provide control and stability.

Directional Guide

!WARNING Never feed the planer attachment in the direction opposite of arrow “Loss of control may occur”. A

directional arrow on the attachment indicates the appropriate feed direction.

For 90 degree planing, use the edge guide to keep planer square to the work piece (6).

For 45 degree chamfer cuts, rotate the rotary tool/planer attachment assembly until the 45 degree angled portion of the edge guide makes flush contact with the side of the work piece (7).

Depth of Cut

Depth of cut is approximately 1/64 inch (.45mm). To assure that planer is cutting to its maximum depth press firmly on the finger grip. Also be sure to keep the planer level with the work surface. This is done by using the hand which holds the rotary tool, and by assuring that the edge guide remains flush to the side of the work surface.

To remove/plane more material, make multiple passes. Sometimes a step or transition point is created while planing if the plane was not

continued the full length of the material. This step or transition point can be removed or blended with the adjacent material by using a carving motion through the transition point. This technique comes with practice, but involves a lighter pressing force on the finger grip so as to plane less material away. At the same time longer strokes are used to blend the adjacent planes together.

Cleaning

!To avoid accidents, always disconnect tool from WARNING the power supply before cleaning or performing

any maintenance. Clean planer if it should become clogged with dust or wood chips. Use caution as cutting bit is sharp.

!CAUTION Certain cleaning agents and solvents damage plastic parts. Some of these are: gasoline, carbon

tetrachloride, chlorinated cleaning solvents, ammonia and household detergents that contain ammonia.

!Always properly support and stabilize the work WARNING piece to prevent accidents.

Planer Lubrication

Your planer comes with a

Normas de seguridad para herramientas mecánicas

Normas de seguridad para herramientas mecánicas

Lea y entienda todas las instrucciones. Si no sigue ! ADVERTENCIA todas las instrucciones que se indican a continua-

ción, el resultado podría ser lesiones corporales.

GUARDE ESTAS INSTRUCCIONES

Normas de seguridad para el aditamento de cepilladora

!Mantenga las manos alejadas del área de corte y ADVERTENCIA de la broca. Mantenga la segunda mano sobre la

carcasa del motor. Si las dos manos están sujetando la herramienta, la broca no puede cortarlas. Sujete firmemente la herramienta para evitar la pérdida de control. Las figuras que aparecen en este manual ilustran el soporte típico de la herramienta con las manos.

Haga avanzar la cepilladora solamente en el sentido indicado.

Use abrazaderas u otro modo práctico para sujetar firmemente y soportar la pieza de trabajo a una plataforma estable. Si se sujeta la pieza de trabajo con la mano o contra el cuerpo, se deja inestable dicha pieza y se podría causar una pérdida de control.

No sujete nunca la pieza que esté cortando con las ! PELIGRO manos o atravesada sobre una pierna. Es importante

soportar apropiadamente la pieza de trabajo para minimizar la exposición del cuerpo, el atasco de la hoja o la pérdida de control.

Use siempre brocas que estén hechas específicamente para este aditamento de cepilladora.

No tenga en marcha la herramienta mientras la lleva a su lado. Un

contacto accidental con la broca que gira podría causar lesiones corporales graves.

Sepa cómo apagar la herramienta en una emergencia. Si el interruptor no

puede apagar rápidamente la herramienta, desenchúfela inmediatamente.

Mantenga un agarre firme con las dos manos sobre la herramienta y posicione el cuerpo y el brazo para permitirle resistir las FUERZAS DE RETROCESO. Las fuerzas de retroceso pueden ser controladas por el operador, si se toman las precauciones adecuadas.