Rho 161 TS specifications

The Durst Rho 161 TS is a state-of-the-art inkjet printer designed specifically for the demands of high-quality printing in various industries. Known for its versatility and efficiency, the Rho 161 TS excels in producing stunning visuals across different media types. It is ideal for printing applications ranging from signage, displays, labels, and packaging to decorative prints.One of the standout features of the Durst Rho 161 TS is its dual-sided printing capability. This allows users to print on both sides of the substrate, thereby increasing productivity and reducing material waste. The printer operates at impressive speeds, with a maximum output of up to 1,000 square meters per hour, making it suitable for bulk production runs without compromising on quality.

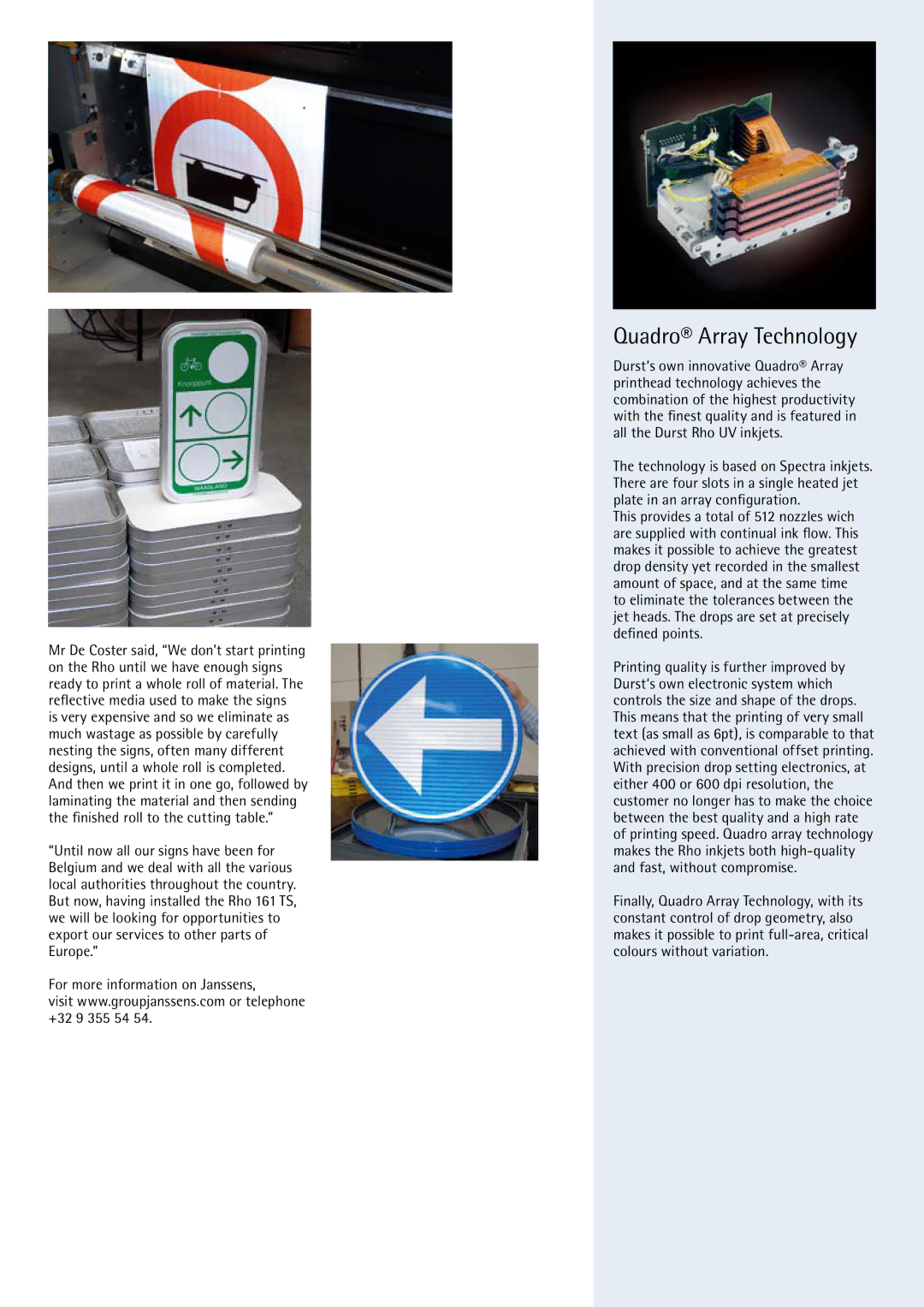

The Rho 161 TS employs advanced UV inkjet technology, which ensures vibrant colors and sharp details in every print. The UV-curable inks provide excellent adhesion to a wide variety of substrates, including rigid materials like plastics, metal, wood, and glass, as well as flexible media. This flexibility opens up new avenues for creativity, allowing businesses to explore various printing applications without constraints.

Another notable characteristic of the Rho 161 TS is its user-friendly interface. The printer is equipped with a touchscreen control panel that simplifies operation and offers quick access to essential functions. This design not only enhances productivity but also minimizes the learning curve for new operators.

Additionally, the Durst Rho 161 TS incorporates advanced automation features, such as intelligent media tracking and registration systems. These technologies help reduce setup times and errors, ensuring consistent and accurate print results. The printer's robust construction also contributes to its reliability, making it a durable solution for demanding printing environments.

In terms of sustainability, the Rho 161 TS is designed with eco-friendly practices in mind. The UV inks used are low in VOCs (volatile organic compounds), contributing to a healthier workplace and a reduced environmental footprint.

Overall, the Durst Rho 161 TS is a powerful, flexible, and sustainable printing solution that meets the high standards of today’s printing industry. Its combination of speed, quality, and versatility makes it an indispensable tool for businesses looking to expand their printing capabilities and deliver exceptional products to their customers.