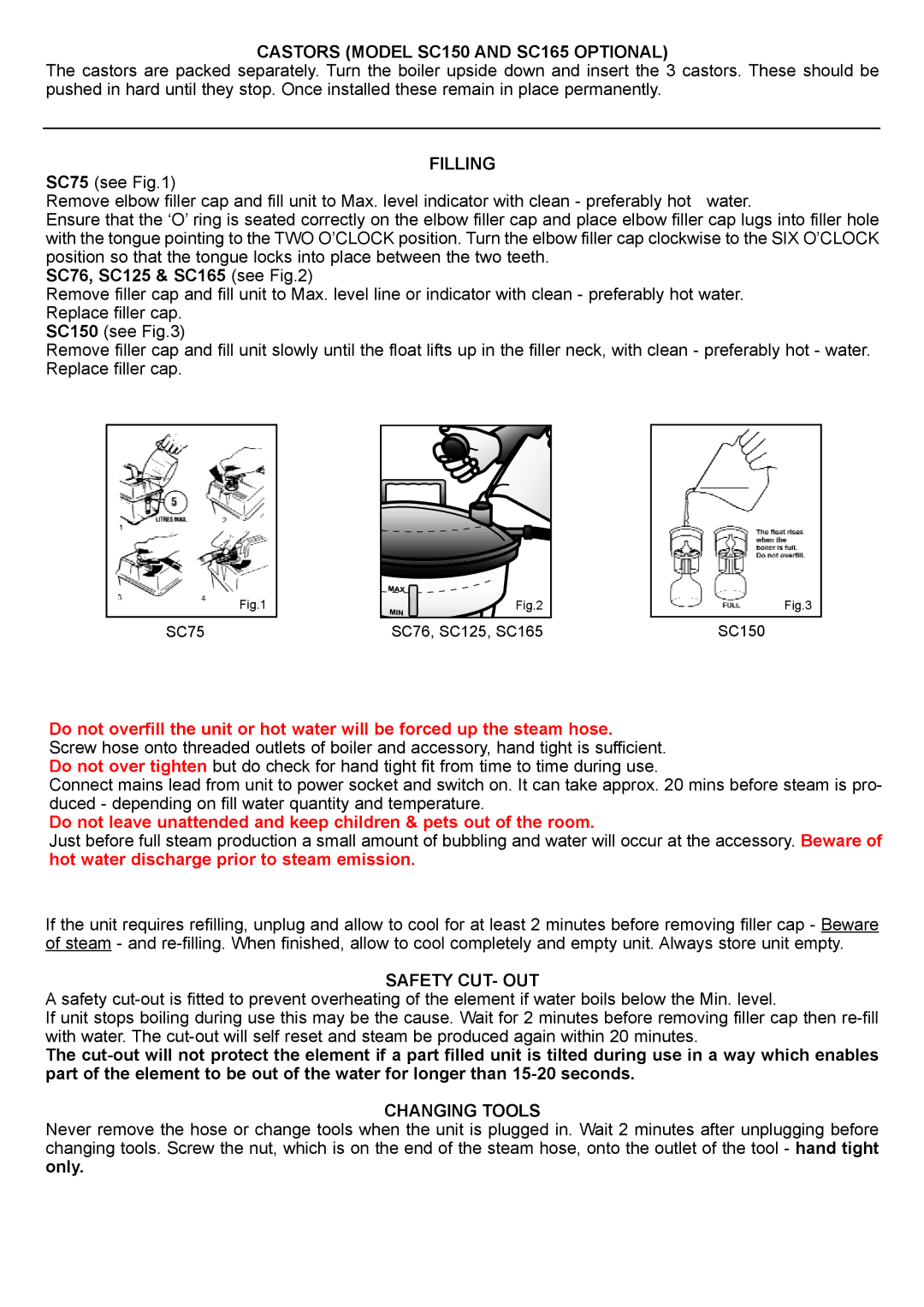

SC75, SC76, SC125, SC165, SC150 specifications

The Earlex range of spray guns, including the SC150, SC165, SC125, SC76, and SC75, are designed to provide high-quality finishing solutions for both professional and DIY users. Each model features advanced technologies tailored to facilitate a smooth painting or staining process, ensuring excellent results across various applications.The Earlex SC150 is known for its high efficiency when it comes to spraying larger surfaces. With a powerful 650W motor, it offers adjustable pressure settings that allow users to adapt the spray output to different materials, making it suitable for everything from thin stains to thicker paints. Its lightweight and ergonomic design ensure minimal fatigue during extended usage.

The SC165 model enhances the user's experience by integrating a 900W motor that delivers a more robust spray pattern. This model features an easy-to-clean design and a built-in turbo fan that helps reduce overspray, which is particularly beneficial for detailed work. With its extensive range of nozzle sizes, users can switch between finishes quickly to achieve precise results.

Designed for versatility, the SC125 model caters to both heavy-duty projects and smaller tasks. It features a unique variable spray control that allows users to fine-tune their spray pattern for various applications. The SC125 is well-regarded for its quick setup and easy maintenance, making it a favorite among both amateurs and seasoned professionals alike.

Moving towards more compact solutions, the SC76 is favored for its portability. With a 650W motor and a lightweight body, it is ideal for those who need a quality finish without the hassle of heavy equipment. The SC76 is equipped with a simple nozzle adjustment mechanism, enabling users to customize their spray width with ease. Its compact size makes it perfect for smaller workshops or home projects.

Finally, the SC75 model closes the range with an emphasis on user-friendliness. It features a straightforward design that allows even beginners to achieve professional results. With its adjustable airflow and easy-to-grip handle, the SC75 provides comfort and control, making it a great entry-level option for aspiring DIY enthusiasts.

Overall, the Earlex SC series combines powerful motors, adjustable settings, and versatile features to provide users with a comprehensive solution for all their spray finishing needs. From professional applications to home projects, these models are designed to deliver impressive results with precision and ease.