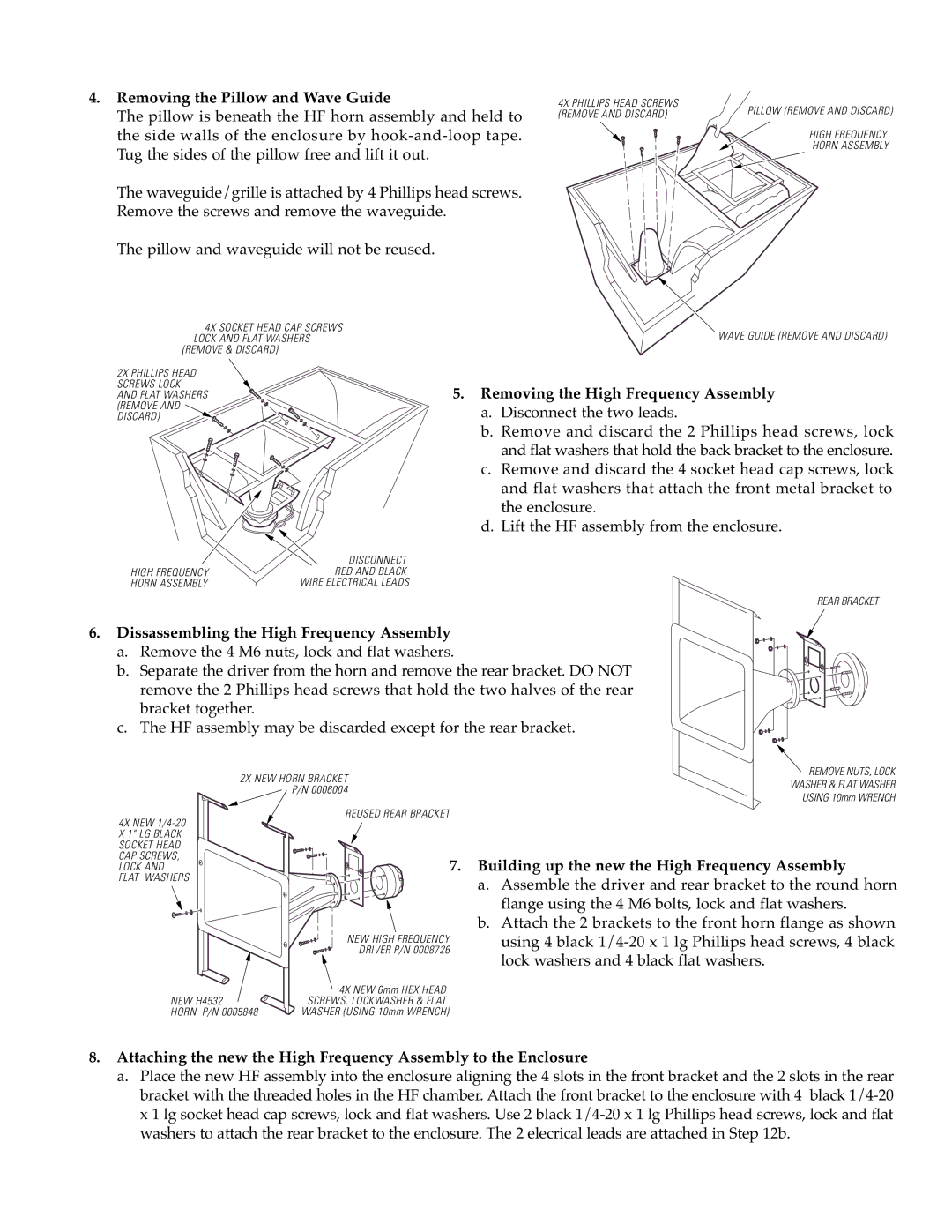

4.Removing the Pillow and Wave Guide

The pillow is beneath the HF horn assembly and held to the side walls of the enclosure by

The waveguide/grille is attached by 4 Phillips head screws. Remove the screws and remove the waveguide.

The pillow and waveguide will not be reused.

4X PHILLIPS HEAD SCREWS | PILLOW (REMOVE AND DISCARD) | |

(REMOVE AND DISCARD) | ||

|

HIGH FREQUENCY

HORN ASSEMBLY

4X SOCKET HEAD CAP SCREWS LOCK AND FLAT WASHERS

(REMOVE & DISCARD)

2X PHILLIPS HEAD SCREWS LOCK AND FLAT WASHERS (REMOVE AND DISCARD)![]()

| DISCONNECT |

HIGH FREQUENCY | RED AND BLACK |

HORN ASSEMBLY | WIRE ELECTRICAL LEADS |

WAVE GUIDE (REMOVE AND DISCARD)

5.Removing the High Frequency Assembly

a.Disconnect the two leads.

b.Remove and discard the 2 Phillips head screws, lock and flat washers that hold the back bracket to the enclosure.

c.Remove and discard the 4 socket head cap screws, lock and flat washers that attach the front metal bracket to the enclosure.

d.Lift the HF assembly from the enclosure.

REAR BRACKET

6.Dissassembling the High Frequency Assembly

a.Remove the 4 M6 nuts, lock and flat washers.

b.Separate the driver from the horn and remove the rear bracket. DO NOT remove the 2 Phillips head screws that hold the two halves of the rear bracket together.

c.The HF assembly may be discarded except for the rear bracket.

2X NEW HORN BRACKET P/N 0006004

REMOVE NUTS, LOCK WASHER & FLAT WASHER USING 10mm WRENCH

4X NEW

NEW H4532

HORN P/N 0005848

REUSED REAR BRACKET

NEW HIGH FREQUENCY

DRIVER P/N 0008726

4X NEW 6mm HEX HEAD SCREWS, LOCKWASHER & FLAT WASHER (USING 10mm WRENCH)

7.Building up the new the High Frequency Assembly

a.Assemble the driver and rear bracket to the round horn flange using the 4 M6 bolts, lock and flat washers.

b.Attach the 2 brackets to the front horn flange as shown using 4 black

8.Attaching the new the High Frequency Assembly to the Enclosure

a.Place the new HF assembly into the enclosure aligning the 4 slots in the front bracket and the 2 slots in the rear bracket with the threaded holes in the HF chamber. Attach the front bracket to the enclosure with 4 black