vocal region and give dialog exceptional warmth and clarity, EAW always employs cone drivers for its mid frequency subsystems.

sound effects. It also permits a greater degree of passive fil- tering to smooth the total system’s frequency response with- out sacrificing peak output.

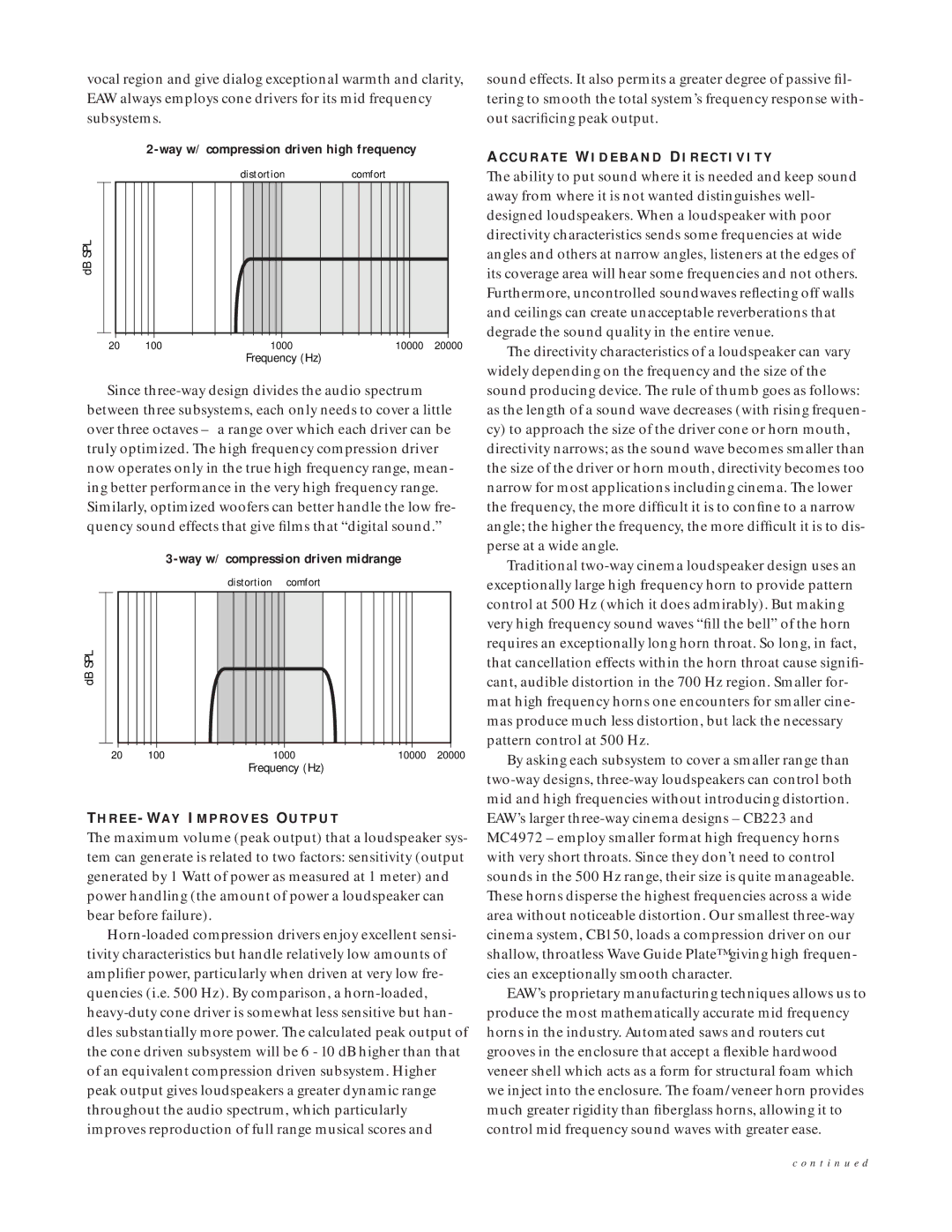

distortioncomfort

dB SPL

20 | 100 | 1000 | 10000 | 20000 |

Frequency (Hz)

Since

distortion comfort

dB SPL

20 | 100 | 1000 | 10000 | 20000 |

|

| Frequency (Hz) |

|

|

T H R E E - W A Y I M P R O V E S O U T P U T

The maximum volume (peak output) that a loudspeaker sys- tem can generate is related to two factors: sensitivity (output generated by 1 Watt of power as measured at 1 meter) and power handling (the amount of power a loudspeaker can bear before failure).

A C C U R A T E W I D E B A N D D I R E C T I V I T Y

The ability to put sound where it is needed and keep sound away from where it is not wanted distinguishes well- designed loudspeakers. When a loudspeaker with poor directivity characteristics sends some frequencies at wide angles and others at narrow angles, listeners at the edges of its coverage area will hear some frequencies and not others. Furthermore, uncontrolled soundwaves reflecting off walls and ceilings can create unacceptable reverberations that degrade the sound quality in the entire venue.

The directivity characteristics of a loudspeaker can vary widely depending on the frequency and the size of the sound producing device. The rule of thumb goes as follows: as the length of a sound wave decreases (with rising frequen- cy) to approach the size of the driver cone or horn mouth, directivity narrows; as the sound wave becomes smaller than the size of the driver or horn mouth, directivity becomes too narrow for most applications including cinema. The lower the frequency, the more difficult it is to confine to a narrow angle; the higher the frequency, the more difficult it is to dis- perse at a wide angle.

Traditional

By asking each subsystem to cover a smaller range than

EAW’s proprietary manufacturing techniques allows us to produce the most mathematically accurate mid frequency horns in the industry. Automated saws and routers cut grooves in the enclosure that accept a flexible hardwood veneer shell which acts as a form for structural foam which we inject into the enclosure. The foam/veneer horn provides much greater rigidity than fiberglass horns, allowing it to control mid frequency sound waves with greater ease.

c o n t i n u e d