10 ![]()

Operation

![]() WARNING

WARNING

Moving parts can amputate fingers or cause severe injuries. Keep hands, clothing and loose objects away from all openings. Always stop engine, disconnect spark plug, and make sure all moving parts have come to a complete stop before removing obstructions, clearing debris, or servicing unit. Allow unit to cool before performing service. Wear gloves to protect hands from sharp edges and hot surfaces.

NOTE

Refer to your Pro Attachment Series power source or Split Boom Operator's Manual for correct engine fueling, starting and stopping instructions.

IMPORTANT

Guide bar cover is for travel/storage only. Remove cover before using unit.

lubricating the guide bar and saw chain

Automatic Oiling System

1. Wipe debris from around oil fill cap.

2.Remove oil fill cap and fill reservoir with a quality, low viscosity guide bar and saw chain oil.

NOTE

The discharge volume of the automatic oiler is preset to deliver 3 to 4 cc/min. at normal operating RPM. During heavy or dry cutting conditions the oil discharge volume may be adjusted to assure ad- equate lubrication. Refill the oil reservoir with each tank of fuel.

IMPORTANT

To prevent plastic deterioration, do not use synthetic or silicone based oil.

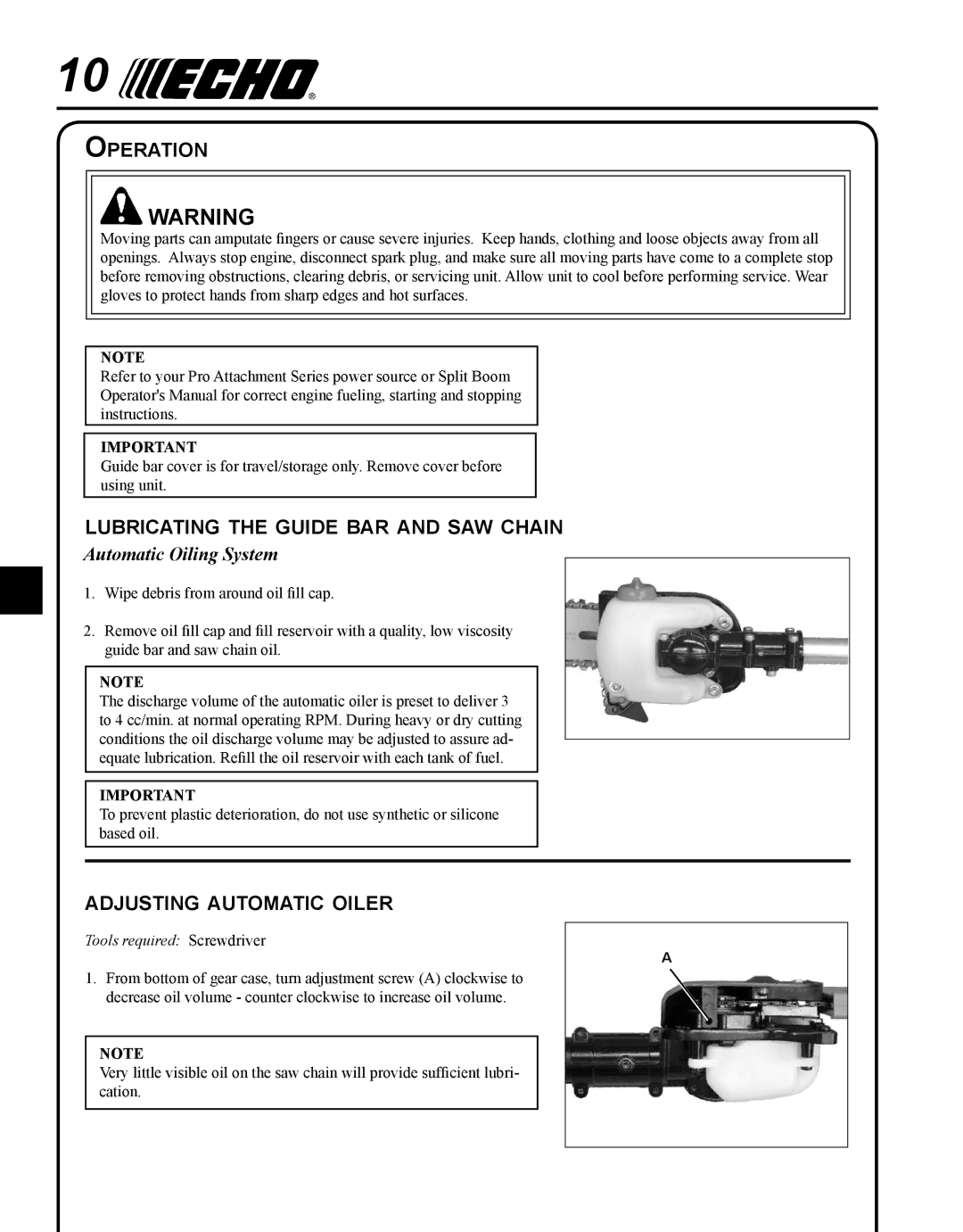

adjusting automatic oiler

Tools required: Screwdriver

1.From bottom of gear case, turn adjustment screw (A) clockwise to decrease oil volume - counter clockwise to increase oil volume.

NOTE

Very little visible oil on the saw chain will provide sufficient lubri- cation.

A