MAINTENANCEPPT-280

Note: Every unit is run at the factory and the carburetor is set in compliance with emission regulations. Carburetor adjustments, other than idle speed, must be performed by an authorized ECHO dealer.

1.Check idle speed and reset if necessary. If a tachometer is available, idle speed screw (A) should be set to the specifications found on “Specifications” page of this manual. Turn idle screw (A) clockwise to increase idle speed; counter clockwise to decrease idle speed.

A

When carburetor adjustment is completed, the cutting attachment should not move at idle, otherwise serious personal injury may result.

Lubrication

Flexible Drive Shaft

Level 1.

Parts Required: POWER BLENDXTM 14 oz.or Lithium Based

Grease

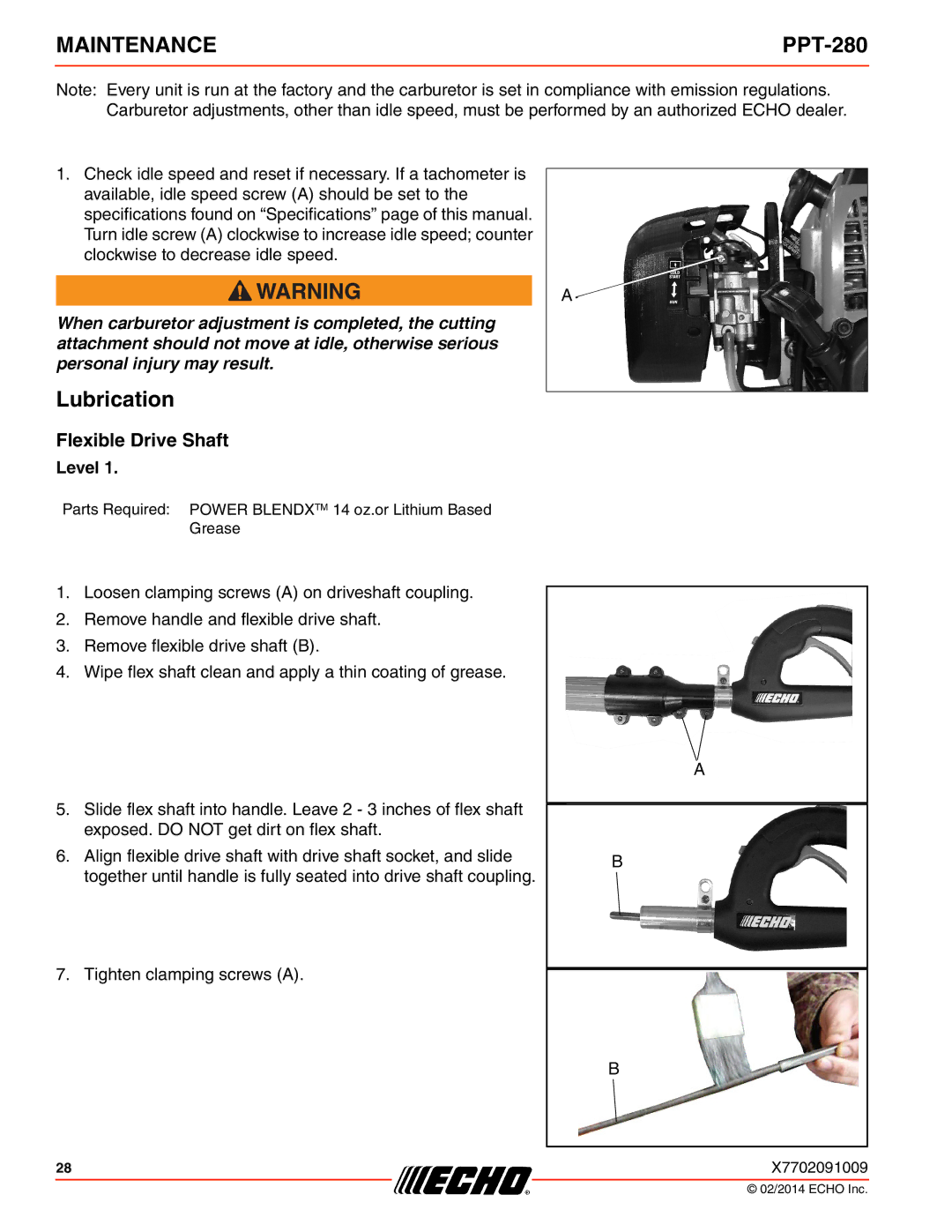

1.Loosen clamping screws (A) on driveshaft coupling.

2.Remove handle and flexible drive shaft.

3.Remove flexible drive shaft (B).

4.Wipe flex shaft clean and apply a thin coating of grease.

5.Slide flex shaft into handle. Leave 2 - 3 inches of flex shaft exposed. DO NOT get dirt on flex shaft.

6.Align flexible drive shaft with drive shaft socket, and slide together until handle is fully seated into drive shaft coupling.

A

B

7. Tighten clamping screws (A).

B

28 | X7702091009 |

© 02/2014 ECHO Inc.