22 ![]()

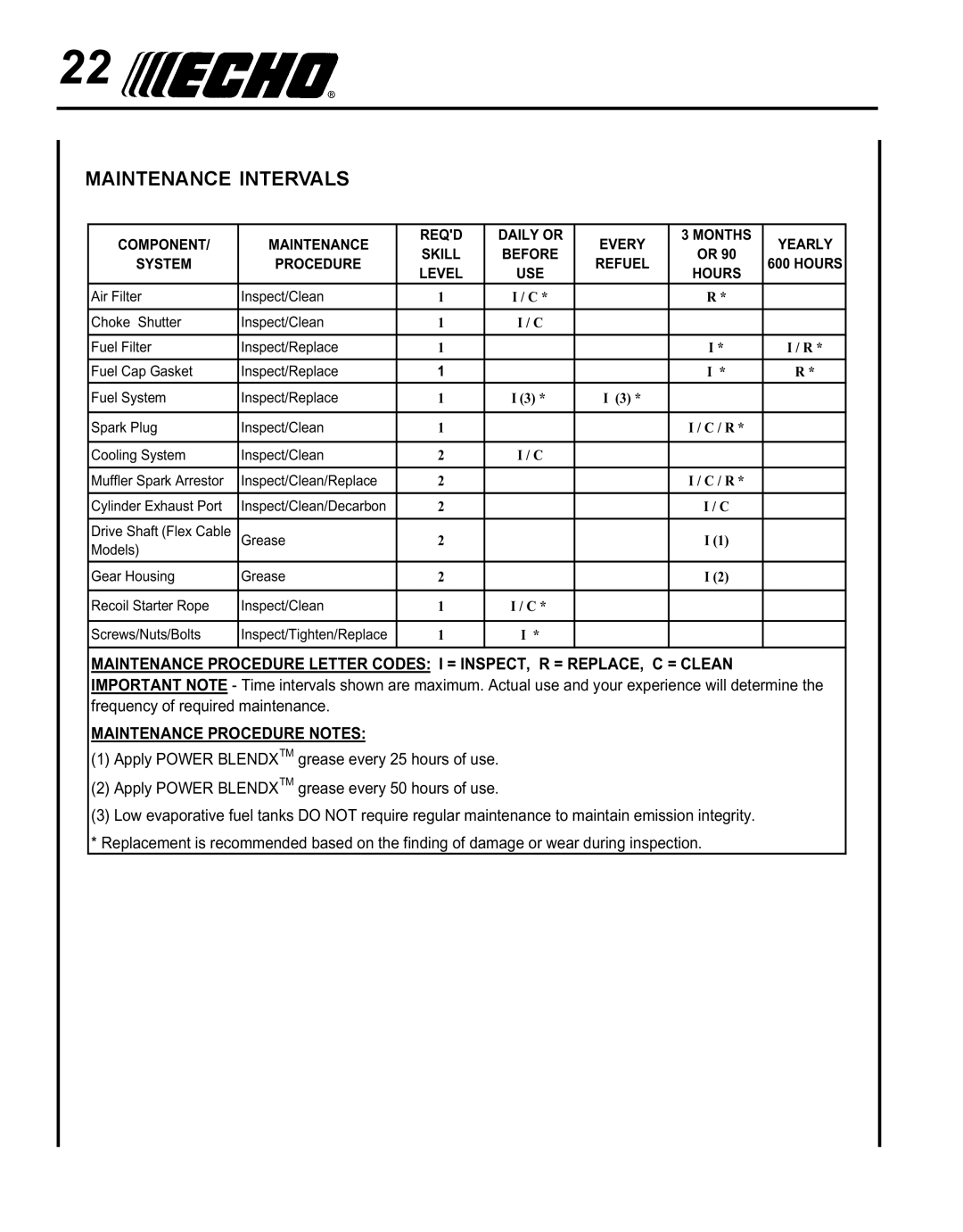

maintenance intervals

COMPONENT/ | MAINTENANCE | REQ'D | DAILY OR | EVERY | 3 MONTHS | YEARLY | |

SKILL | BEFORE | OR 90 | |||||

SYSTEM | PROCEDURE | REFUEL | 600 HOURS | ||||

LEVEL | USE | HOURS | |||||

|

|

|

| ||||

Air Filter | Inspect/Clean | 1 | I / C * |

| R * |

| |

|

|

|

|

|

|

| |

Choke Shutter | Inspect/Clean | 1 | I / C |

|

|

| |

|

|

|

|

|

|

| |

Fuel Filter | Inspect/Replace | 1 |

|

| I * | I / R * | |

|

|

|

|

|

|

| |

Fuel Cap Gasket | Inspect/Replace | 1 |

|

| I * | R * | |

Fuel System | Inspect/Replace | 1 | I (3) * | I (3) * |

|

| |

|

|

|

|

|

|

| |

Spark Plug | Inspect/Clean | 1 |

|

| I / C / R * |

| |

|

|

|

|

|

|

| |

Cooling System | Inspect/Clean | 2 | I / C |

|

|

| |

|

|

|

|

|

|

| |

Muffler Spark Arrestor | Inspect/Clean/Replace | 2 |

|

| I / C / R * |

| |

|

|

|

|

|

|

| |

Cylinder Exhaust Port | Inspect/Clean/Decarbon | 2 |

|

| I / C |

| |

|

|

|

|

|

|

| |

Drive Shaft (Flex Cable | Grease | 2 |

|

| I (1) |

| |

Models) |

|

|

|

|

|

| |

Gear Housing | Grease | 2 |

|

| I (2) |

| |

|

|

|

|

|

|

| |

Recoil Starter Rope | Inspect/Clean | 1 | I / C * |

|

|

| |

|

|

|

|

|

|

| |

Screws/Nuts/Bolts | Inspect/Tighten/Replace | 1 | I * |

|

|

| |

|

|

|

|

|

|

|

MAINTENANCE PROCEDURE LETTER CODES: I = INSPECT, R = REPLACE, C = CLEAN IMPORTANT NOTE - Time intervals shown are maximum. Actual use and your experience will determine the frequency of required maintenance.

MAINTENANCE PROCEDURE NOTES:

(1) Apply POWER BLENDXTM grease every 25 hours of use.

(2) Apply POWER BLENDXTM grease every 50 hours of use.

(3) Low evaporative fuel tanks DO NOT require regular maintenance to maintain emission integrity. * Replacement is recommended based on the finding of damage or wear during inspection.