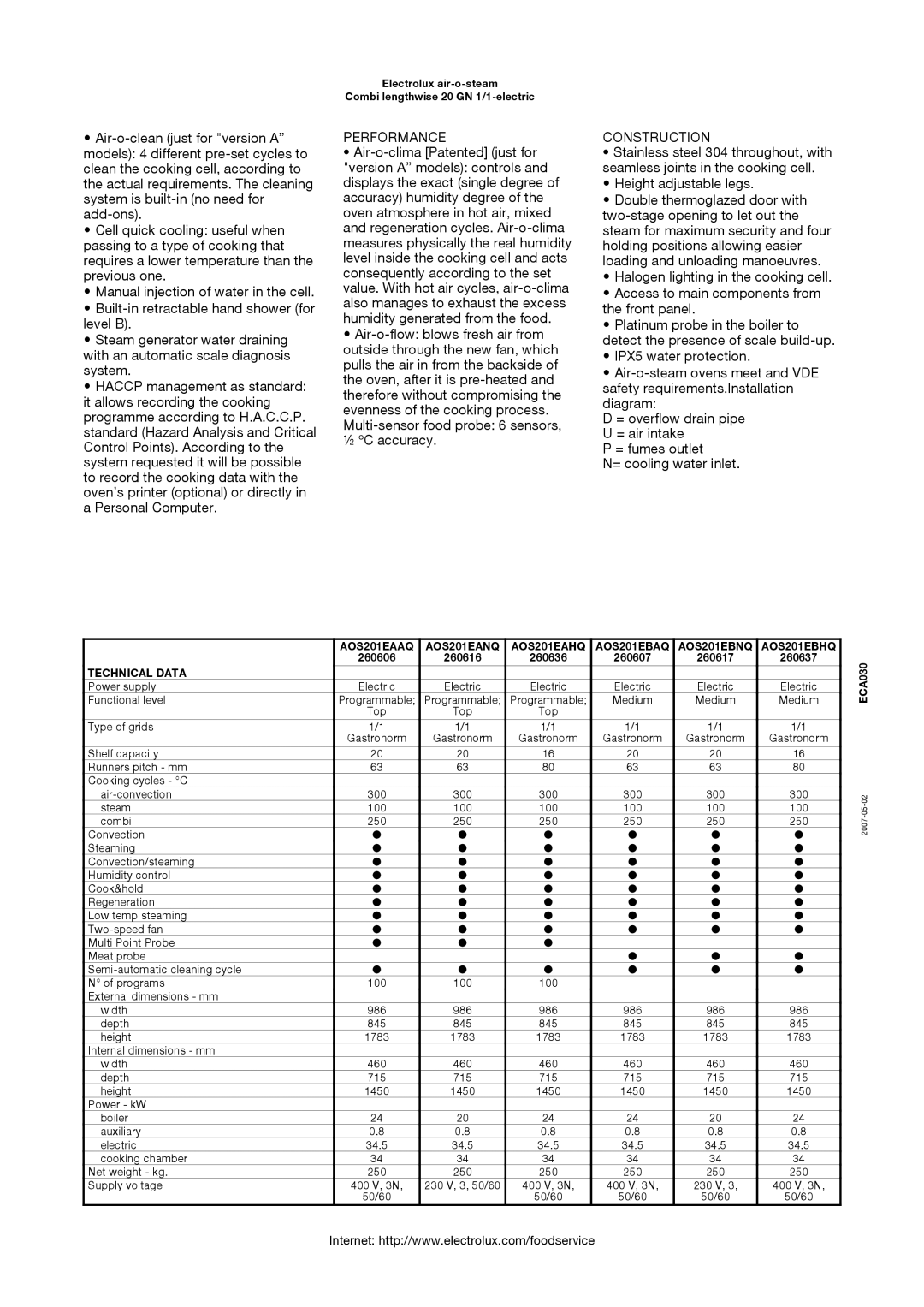

20 GN specifications

Electrolux 20 GN is a highly acclaimed commercial refrigerator designed to optimize storage in professional kitchen environments. Known for its robust construction and energy efficiency, it has become a staple for restaurants, catering services, and food establishments looking to keep food fresh while minimizing energy consumption.One of the main features of the Electrolux 20 GN is its generous capacity. With numerous shelves available, it comfortably accommodates various types of food and ingredients, allowing chefs easy access and efficient organization. The 20 GN model specifically caters to the GN (Gastronorm) standards, making it compatible with a wide range of GN pans, which is essential for both storage and transportation purposes.

The cooling technology utilized in the Electrolux 20 GN ensures a consistent temperature throughout the unit. It incorporates a forced air cooling system that evenly distributes cold air within the refrigerator, preventing warm spots and maintaining optimal conditions for perishable items. This technology not only enhances food preservation but also helps in reducing spoilage, leading to cost savings for the business.

Energy efficiency is another critical characteristic of the Electrolux 20 GN. It is designed with eco-friendly refrigerants and insulation materials that contribute to lower energy consumption. This is especially important in commercial settings where appliances run continuously, and even slight energy savings can result in significant cost reductions over time.

Additionally, the Electrolux 20 GN is equipped with user-friendly controls that make operation straightforward for kitchen staff. The intuitive digital display allows for precise temperature settings, and alerts can be set for door openings, ensuring that the cold chain is never compromised.

Durability is a hallmark of Electrolux products, and the 20 GN is no exception. Made with high-quality stainless steel, it is designed to withstand the rigors of a busy kitchen environment. Its smooth surfaces make for easy cleaning, which is essential in maintaining hygiene standards.

In conclusion, the Electrolux 20 GN combines generous storage capacity, advanced cooling technologies, energy efficiency, and durability. These features make it an ideal choice for any commercial kitchen seeking reliability and performance in food storage solutions. Whether used in restaurants, hotels, or catering companies, the Electrolux 20 GN is poised to meet the demanding needs of the food service industry.