SERVICE CHECK

SERVICE CHECK

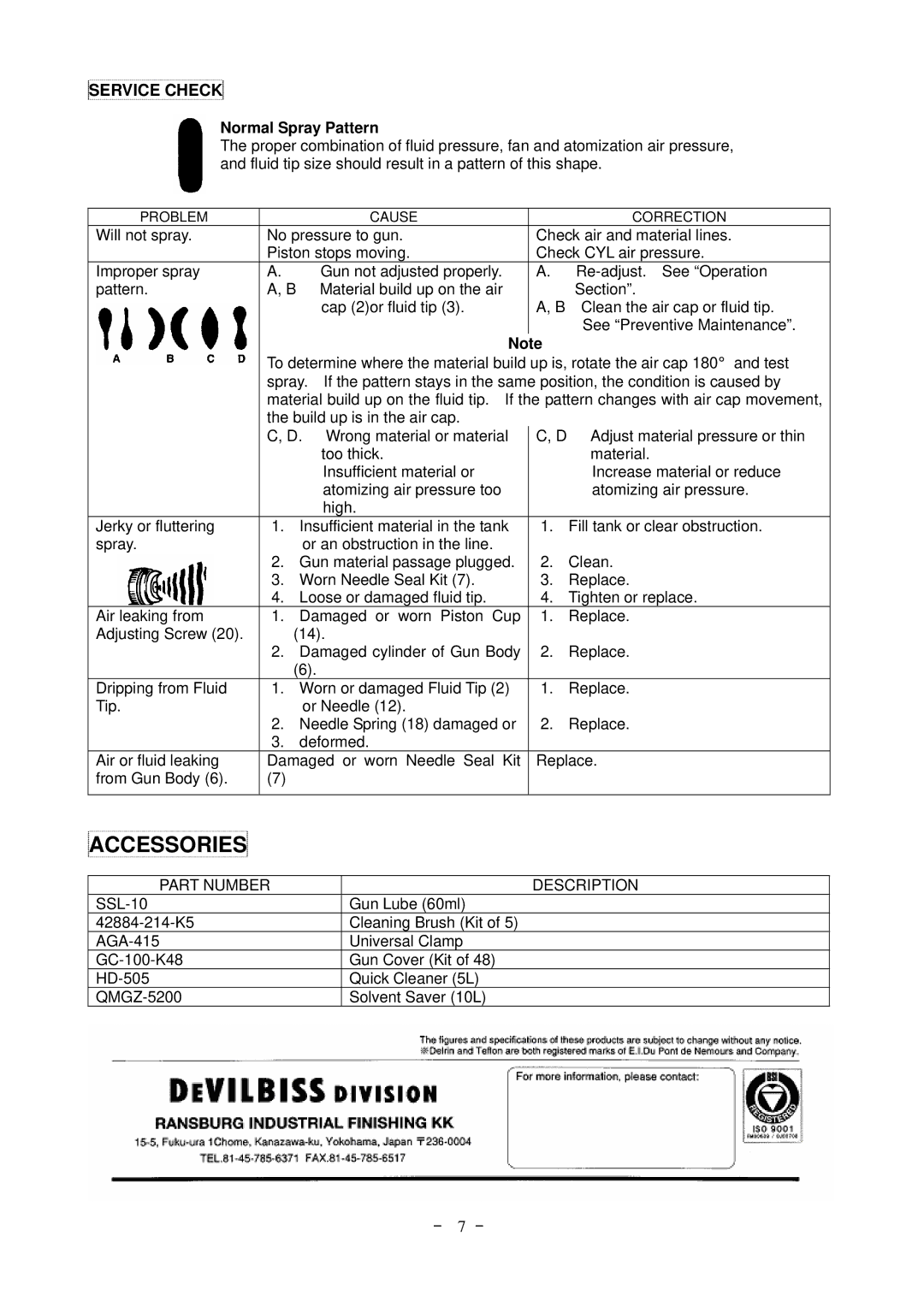

Normal Spray Pattern

The proper combination of fluid pressure, fan and atomization air pressure, and fluid tip size should result in a pattern of this shape.

|

| PROBLEM |

|

| CAUSE |

| CORRECTION | |

| Will not spray. |

| No pressure to gun. | Check air and material lines. | ||||

|

|

|

|

| Piston stops moving. | Check CYL air pressure. | ||

| Improper spray |

| A. | Gun not adjusted properly. | A. | |||

| pattern. |

| A, B Material build up on the air |

| Section”. | |||

|

|

|

|

|

| cap (2)or fluid tip (3). | A, B Clean the air cap or fluid tip. | |

|

|

|

|

|

| |||

|

|

|

|

|

|

|

| See “Preventive Maintenance”. |

|

|

|

|

|

| Note |

| |

|

|

|

|

| To determine where the material build up is, rotate the air cap 180°and test | |||

|

|

|

| |||||

|

|

|

|

| spray. If the pattern stays in the same position, the condition is caused by | |||

|

|

|

|

| material build up on the fluid tip. If the pattern changes with air cap movement, | |||

|

|

|

|

| the build up is in the air cap. |

|

| |

|

|

|

|

| C, D. Wrong material or material | C, D Adjust material pressure or thin | ||

|

|

|

|

|

| too thick. |

| material. |

|

|

|

|

|

| Insufficient material or |

| Increase material or reduce |

|

|

|

|

|

| atomizing air pressure too |

| atomizing air pressure. |

|

|

|

|

|

| high. |

|

|

| Jerky or fluttering |

| 1. | Insufficient material in the tank | 1. | Fill tank or clear obstruction. | ||

| spray. |

|

| or an obstruction in the line. |

|

| ||

|

|

|

|

| 2. | Gun material passage plugged. | 2. | Clean. |

|

|

|

|

| 3. | Worn Needle Seal Kit (7). | 3. | Replace. |

|

|

|

|

| 4. | Loose or damaged fluid tip. | 4. | Tighten or replace. |

|

|

|

|

|

|

|

|

|

| Air leaking from |

| 1. | Damaged or worn Piston Cup | 1. | Replace. | ||

| Adjusting Screw (20). |

|

| (14). |

|

| ||

|

|

|

|

| 2. | Damaged cylinder of Gun Body | 2. | Replace. |

|

|

|

|

|

| (6). |

|

|

| Dripping from Fluid |

| 1. | Worn or damaged Fluid Tip (2) | 1. | Replace. | ||

| Tip. |

|

| or Needle (12). |

|

| ||

|

|

|

|

| 2. | Needle Spring (18) damaged or | 2. | Replace. |

|

|

|

|

| 3. | deformed. |

|

|

| Air or fluid leaking |

| Damaged or worn Needle Seal Kit | Replace. | ||||

| from Gun Body (6). |

| (7) |

|

|

| ||

|

|

|

|

|

|

|

|

|

ACCESSORIES

ACCESSORIES

PART NUMBER | DESCRIPTION |

Gun Lube (60ml) | |

Cleaning Brush (Kit of 5) | |

Universal Clamp | |

Gun Cover (Kit of 48) | |

Quick Cleaner (5L) | |

Solvent Saver (10L) |