|

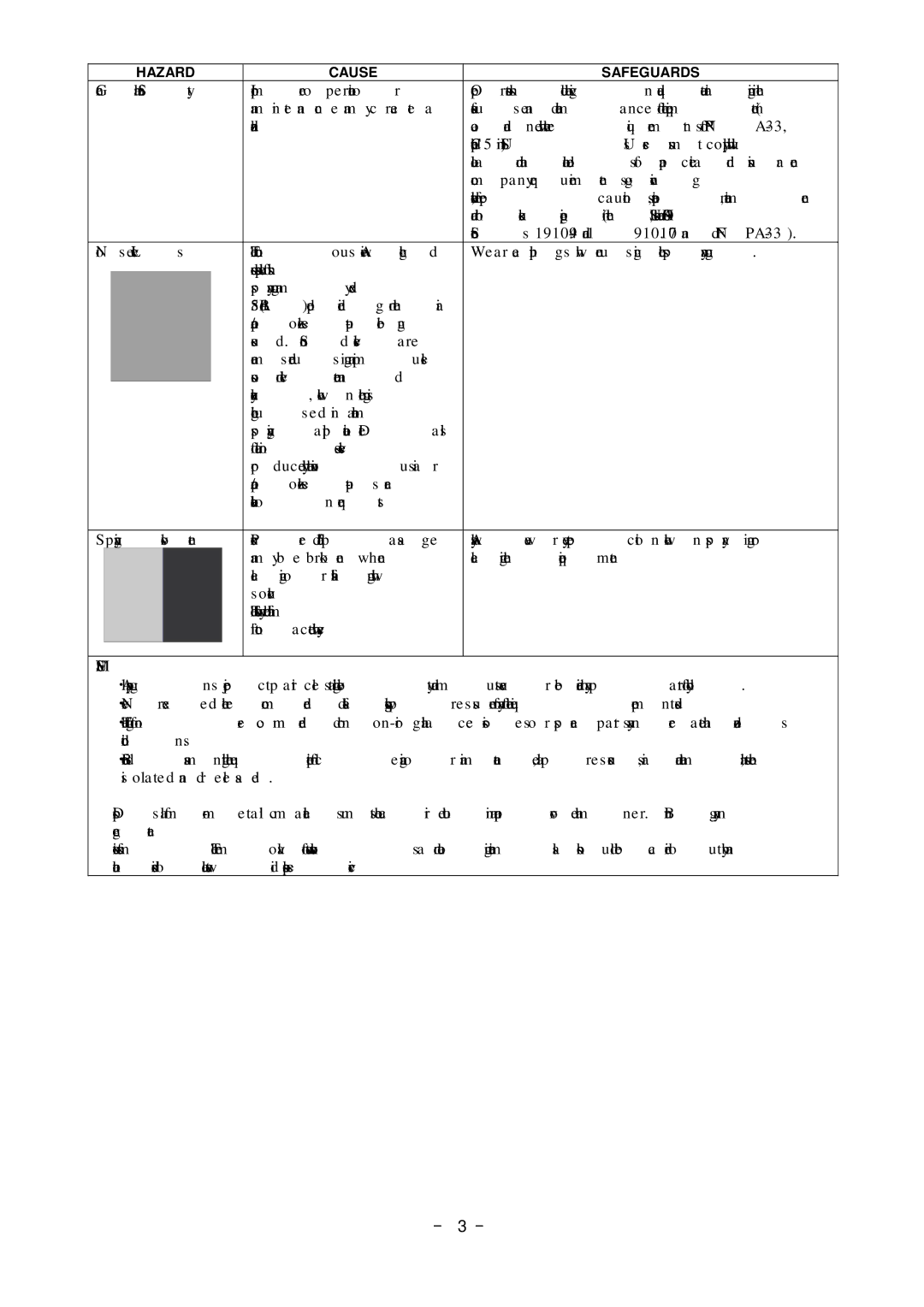

| HAZARD | CAUSE | SAFEGUARDS | ||

General Safety | Improper operation or | Operators should be given adequate training in the | ||||

|

|

|

|

| maintenance may create a | safe use and maintenance of the equipment (in |

|

|

|

|

| hazard. | accordance with the requirements of |

|

|

|

|

|

| Chapter 15 in U.S.). Users must comply with all |

|

|

|

|

|

| local and national codes of practice and insurance |

|

|

|

|

|

| company requirements governing |

|

|

|

|

|

| ventilation, fire precautions, operation, maintenance |

|

|

|

|

|

| and housekeeping (in the U.S., these are OSHA |

|

|

|

|

|

| Sections 1910.94 and 1910.107 and |

Noise Levels | The continuous | Wear earplugs when using the spray gun. | ||||

|

|

|

|

| sound pressure level of this |

|

|

|

|

|

|

| |

|

|

|

|

| spray gun may exceed |

|

|

|

|

|

| 85dB(A) depending on the air |

|

|

|

|

|

| cap/nozzle |

|

|

|

|

|

| used. Sound levels are |

|

|

|

|

|

| measured using an impulse |

|

|

|

|

|

| sound level meter and |

|

|

|

|

|

|

| |

|

|

|

|

| analyzer, when the gun is |

|

|

|

|

|

| being used in a normal |

|

|

|

|

|

| spraying application. Details |

|

|

|

|

|

| of actual noise levels |

|

|

|

|

|

| produced by the various air |

|

|

|

|

|

| cap/nozzle |

|

|

|

|

|

| available on request. |

|

|

|

|

|

|

|

|

Spraying solvent | Pressured air/fluid passage | Always wear eye protection when spraying or | ||||

|

|

|

|

| may be broken when | cleaning the equipment. |

|

|

|

|

| cleaning or flashing with |

|

|

|

|

|

| solvent. |

|

|

|

|

|

| The solvent may be harmful |

|

|

|

|

|

| if contacted with eyes. |

|

|

|

|

|

|

|

|

MISUES:

・All spray guns project particles at high velocity and must never be aimed t any part of body. ・Never exceed the recommended safe working pressure for any of the equipment used.

・The fitting of

・Before dismantling the equipment for cleaning or maintenance, all pressures, air and material, must be isolated and released.

Disposal of

toxic fumes. The removal of waste solvents and coating materials should be carried out by an authorised local waste disposal service.