Specification Sheet | 2.5:DVS205 |

January 2009 |

DVS205 Dual-Variable Sensor

The DVS205

Variables

Functionally, the DVS is a digital transmitter that measures two

Transducer and Electronics

The DVS contains a transducer and an electronics circuit. The transducer uses

The transducer electronics convert the pressure variables directly into a digital format, allowing

accurate correction and compensation. A microprocessor linearizes and corrects the raw pressure signals (from the sensor) using characterization data stored in

The electronics also allow the DVS to communicate with a FloBoss using a Serial Peripheral Interface (SPI).

Accuracy

Two versions of the DVS transmitter are available:

DVS205P with reference accuracy of 0.075% of the full span.

DVS205E with reference accuracy of 0.10% of the full span.

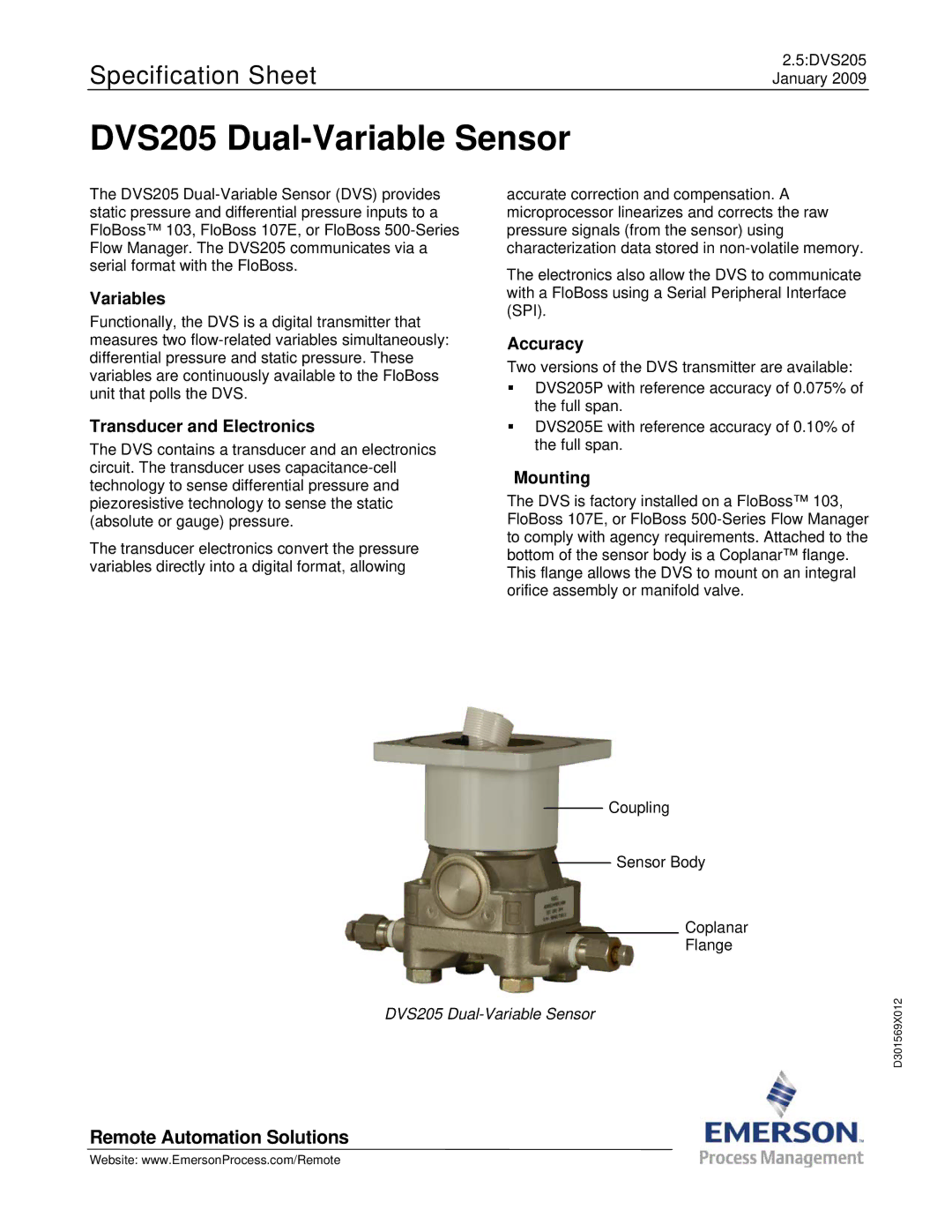

Mounting

The DVS is factory installed on a FloBoss™ 103, FloBoss 107E, or FloBoss

Coupling

Sensor Body

Coplanar

Flange

DVS205

D301569X012

Remote Automation Solutions

Website: www.EmersonProcess.com/Remote