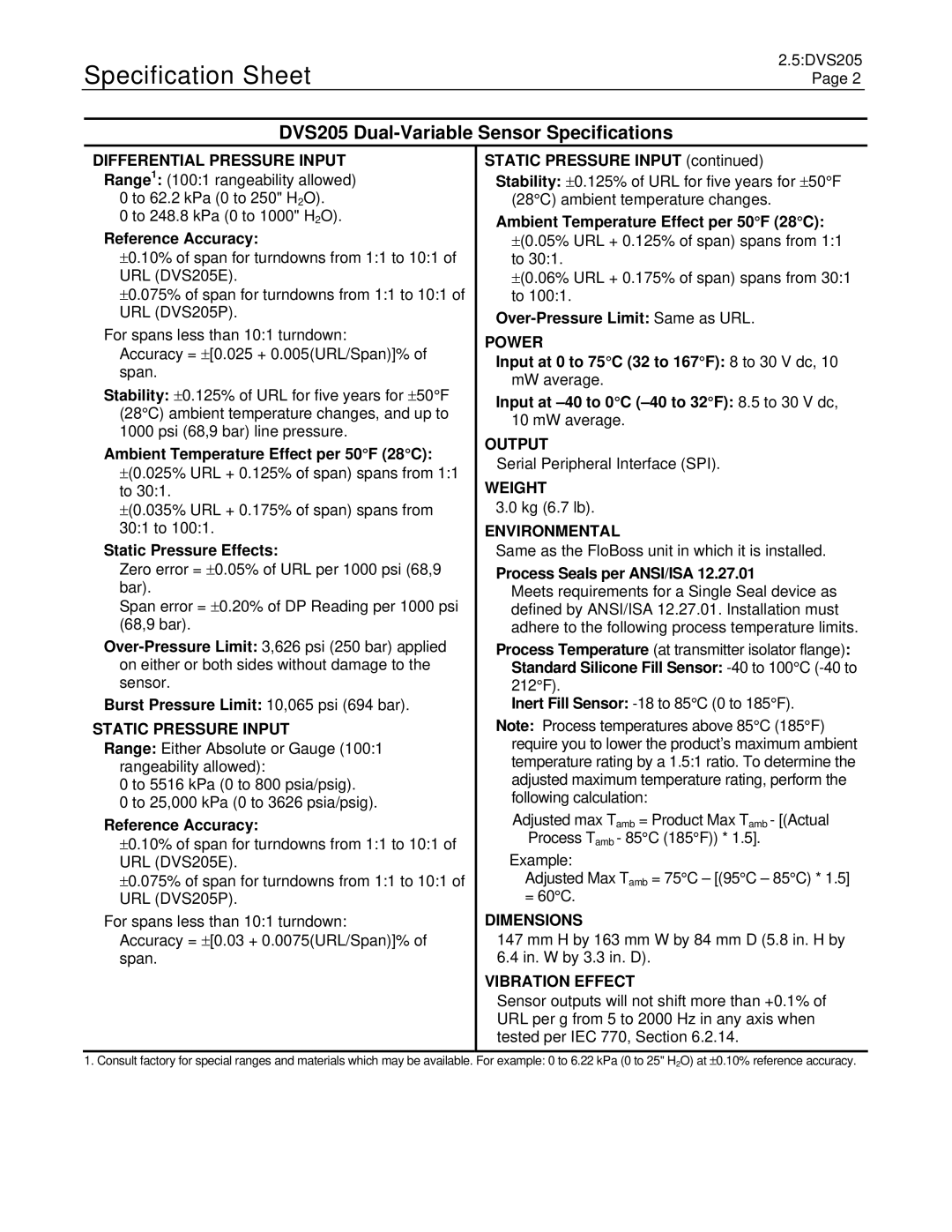

Specification Sheet

2.5:DVS205 Page 2

DVS205 Dual-Variable Sensor Specifications

DIFFERENTIAL PRESSURE INPUT | STATIC PRESSURE INPUT (continued) | |

Range1: (100:1 rangeability allowed) | Stability: ±0.125% of URL for five years for ±50°F | |

0 to 62.2 kPa (0 to 250" H2O). | (28°C) ambient temperature changes. | |

0 to 248.8 kPa (0 to 1000" H2O). | Ambient Temperature Effect per 50°F (28°C): | |

Reference Accuracy: | ±(0.05% URL + 0.125% of span) spans from 1:1 | |

±0.10% of span for turndowns from 1:1 to 10:1 of | to 30:1. | |

URL (DVS205E). | ±(0.06% URL + 0.175% of span) spans from 30:1 | |

±0.075% of span for turndowns from 1:1 to 10:1 of | to 100:1. | |

URL (DVS205P). | ||

For spans less than 10:1 turndown: | ||

POWER | ||

Accuracy = ±[0.025 + 0.005(URL/Span)]% of | ||

Input at 0 to 75°C (32 to 167°F): 8 to 30 V dc, 10 | ||

span. | ||

mW average. | ||

Stability: ±0.125% of URL for five years for ±50°F | ||

Input at | ||

(28°C) ambient temperature changes, and up to | ||

10 mW average. | ||

1000 psi (68,9 bar) line pressure. | ||

OUTPUT | ||

Ambient Temperature Effect per 50°F (28°C): | ||

Serial Peripheral Interface (SPI). | ||

±(0.025% URL + 0.125% of span) spans from 1:1 | ||

WEIGHT | ||

to 30:1. | ||

±(0.035% URL + 0.175% of span) spans from | 3.0 kg (6.7 lb). | |

30:1 to 100:1. | ENVIRONMENTAL | |

Static Pressure Effects: | Same as the FloBoss unit in which it is installed. | |

Zero error = ±0.05% of URL per 1000 psi (68,9 | Process Seals per ANSI/ISA 12.27.01 | |

bar). | Meets requirements for a Single Seal device as | |

Span error = ±0.20% of DP Reading per 1000 psi | defined by ANSI/ISA 12.27.01. Installation must | |

(68,9 bar). | adhere to the following process temperature limits. | |

Process Temperature (at transmitter isolator flange): | ||

on either or both sides without damage to the | Standard Silicone Fill Sensor: | |

sensor. | 212°F). | |

Burst Pressure Limit: 10,065 psi (694 bar). | Inert Fill Sensor: | |

STATIC PRESSURE INPUT | Note: Process temperatures above 85°C (185°F) | |

Range: Either Absolute or Gauge (100:1 | require you to lower the product’s maximum ambient | |

rangeability allowed): | temperature rating by a 1.5:1 ratio. To determine the | |

0 to 5516 kPa (0 to 800 psia/psig). | adjusted maximum temperature rating, perform the | |

0 to 25,000 kPa (0 to 3626 psia/psig). | following calculation: | |

Reference Accuracy: | Adjusted max Tamb = Product Max Tamb - [(Actual | |

Process Tamb - 85°C (185°F)) * 1.5]. | ||

±0.10% of span for turndowns from 1:1 to 10:1 of | ||

Example: | ||

URL (DVS205E). | ||

±0.075% of span for turndowns from 1:1 to 10:1 of | Adjusted Max Tamb = 75°C – [(95°C – 85°C) * 1.5] | |

URL (DVS205P). | = 60°C. | |

For spans less than 10:1 turndown: | DIMENSIONS | |

Accuracy = ±[0.03 + 0.0075(URL/Span)]% of | 147 mm H by 163 mm W by 84 mm D (5.8 in. H by | |

span. | 6.4 in. W by 3.3 in. D). | |

| VIBRATION EFFECT | |

| Sensor outputs will not shift more than +0.1% of | |

| URL per g from 5 to 2000 Hz in any axis when | |

| tested per IEC 770, Section 6.2.14. |

1. Consult factory for special ranges and materials which may be available. For example: 0 to 6.22 kPa (0 to 25" H2O) at ±0.10% reference accuracy.