Performance |

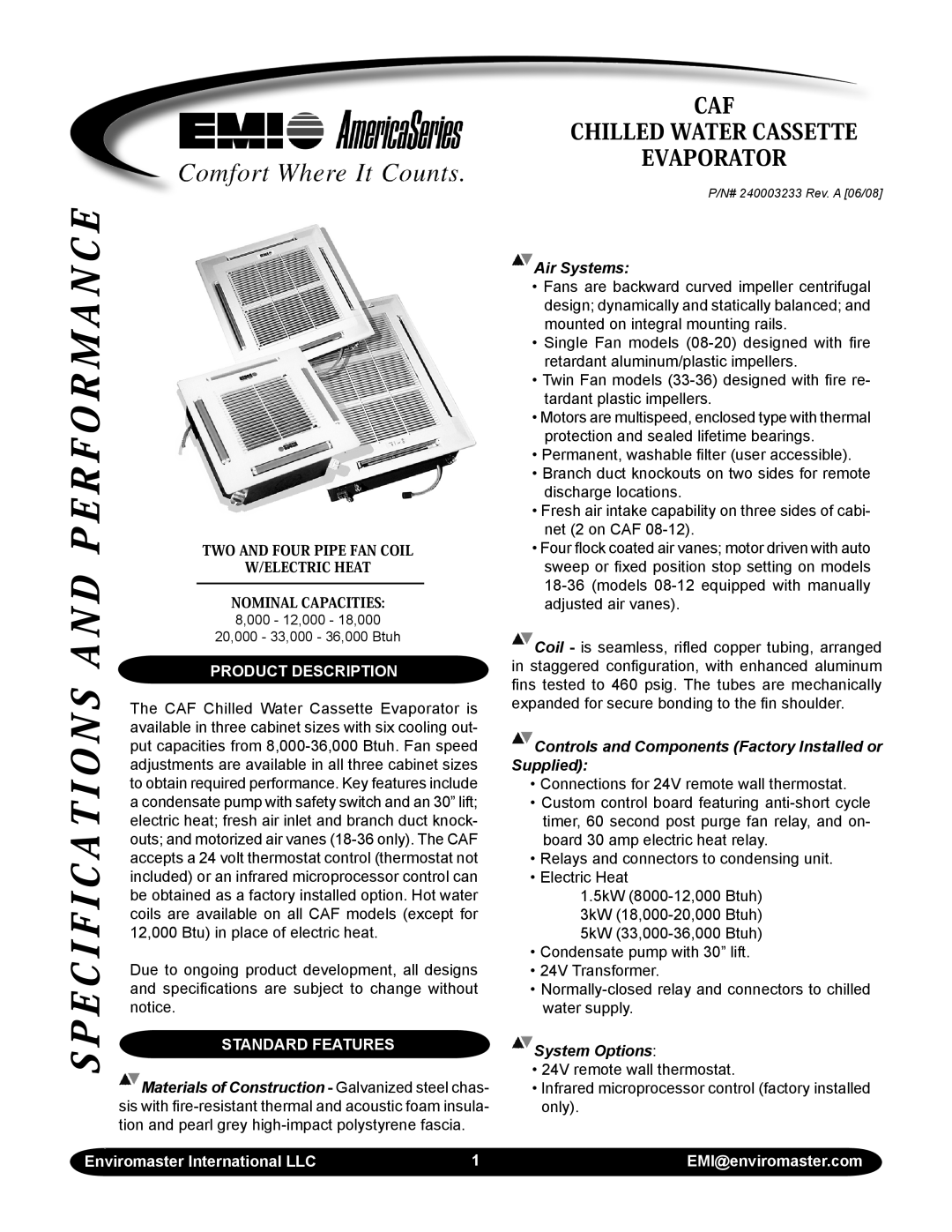

| TWO AND FOUR PIPE FAN COIL |

| ||

and |

| W/ELECTRIC HEAT |

| ||

|

|

|

| ||

| Nominal Capacities: |

| |||

|

|

| |||

| 8,000 - 12,000 - 18,000 |

|

| ||

|

| 20,000 - 33,000 - 36,000 Btuh |

| ||

ns |

| product Description |

| ||

The CAF Chilled Water Cassette Evaporator is | |||||

| |||||

| available in three cabinet sizes with six cooling out- | ||||

o | put capacities from | ||||

adjustments are available in all three cabinet sizes | |||||

| |||||

i | to obtain required performance. Key features include | ||||

a condensate pump with safety switch and an 30” lift; | |||||

| |||||

t electric heat; fresh air inlet and branch duct knock- | |||||

a | outs; and motorized air vanes | ||||

accepts a 24 volt thermostat control (thermostat not | |||||

c | |||||

included) or an infrared microprocessor control can | |||||

be obtained as a factory installed option. Hot water | |||||

i | |||||

coils are available on all CAF models (except for | |||||

f | |||||

12,000 Btu) in place of electric heat. |

| ||||

i | Due to ongoing product development, all designs | ||||

c | |||||

and specifications are subject to change without | |||||

| |||||

e notice. |

| ||||

p |

| Standard Features |

| ||

S |

|

| |||

|

|

|

| ||

| Materials of Construction - Galvanized steel chas- | ||||

| sis with | ||||

| tion and pearl grey |

| |||

Enviromaster International LLC | 1 | ||||

CAf

chilled water CASSETTE

EVAPORATOR

p/n# 240003233 rev. A [06/08]

Air Systems:

Air Systems:

•Fans are backward curved impeller centrifugal design; dynamically and statically balanced; and mounted on integral mounting rails.

•Single Fan models

•Twin Fan models

•Motors are multispeed, enclosed type with thermal protection and sealed lifetime bearings.

•Permanent, washable filter (user accessible).

•Branch duct knockouts on two sides for remote discharge locations.

•Fresh air intake capability on three sides of cabi- net (2 on CAF

•Four flock coated air vanes; motor driven with auto sweep or fixed position stop setting on models

![]() Coil - is seamless, rifled copper tubing, arranged in staggered configuration, with enhanced aluminum fins tested to 460 psig. The tubes are mechanically expanded for secure bonding to the fin shoulder.

Coil - is seamless, rifled copper tubing, arranged in staggered configuration, with enhanced aluminum fins tested to 460 psig. The tubes are mechanically expanded for secure bonding to the fin shoulder.

Controls and Components (factory installed or supplied):

•Connections for 24V remote wall thermostat.

•Custom control board featuring

•Relays and connectors to condensing unit.

•Electric Heat

1.5kW

•Condensate pump with 30” lift.

•24v Transformer.

•

System Options:

System Options:

•24v remote wall thermostat.

•Infrared microprocessor control (factory installed only).

EMI@enviromaster.com