383823-01/DW870 5/3/02 1:33 PM Page 11

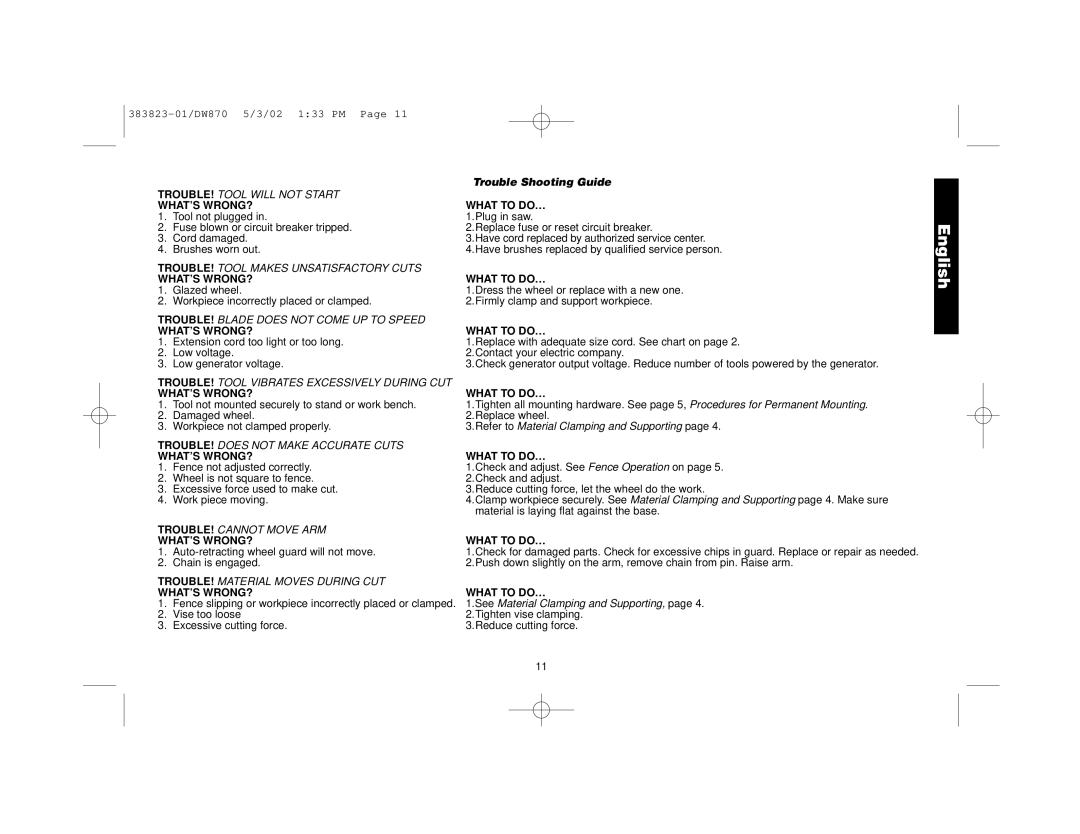

TROUBLE! TOOL WILL NOT START | Trouble Shooting Guide | |

| ||

WHAT’S WRONG? | WHAT TO DO… | |

1. | Tool not plugged in. | 1.Plug in saw. |

2. | Fuse blown or circuit breaker tripped. | 2.Replace fuse or reset circuit breaker. |

3. | Cord damaged. | 3.Have cord replaced by authorized service center. |

4. | Brushes worn out. | 4.Have brushes replaced by qualified service person. |

TROUBLE! TOOL MAKES UNSATISFACTORY CUTS |

| |

WHAT’S WRONG? | WHAT TO DO… | |

1. | Glazed wheel. | 1.Dress the wheel or replace with a new one. |

2. | Workpiece incorrectly placed or clamped. | 2.Firmly clamp and support workpiece. |

TROUBLE! BLADE DOES NOT COME UP TO SPEED |

| |

WHAT’S WRONG? | WHAT TO DO… | |

1. | Extension cord too light or too long. | 1.Replace with adequate size cord. See chart on page 2. |

2. | Low voltage. | 2.Contact your electric company. |

3. | Low generator voltage. | 3.Check generator output voltage. Reduce number of tools powered by the generator. |

TROUBLE! TOOL VIBRATES EXCESSIVELY DURING CUT |

| |

WHAT’S WRONG? | WHAT TO DO… | |

1. | Tool not mounted securely to stand or work bench. | 1.Tighten all mounting hardware. See page 5, Procedures for Permanent Mounting. |

2. | Damaged wheel. | 2.Replace wheel. |

3. | Workpiece not clamped properly. | 3.Refer to Material Clamping and Supporting page 4. |

TROUBLE! DOES NOT MAKE ACCURATE CUTS |

| |

WHAT’S WRONG? | WHAT TO DO… | |

1. | Fence not adjusted correctly. | 1.Check and adjust. See Fence Operation on page 5. |

2. | Wheel is not square to fence. | 2.Check and adjust. |

3. | Excessive force used to make cut. | 3.Reduce cutting force, let the wheel do the work. |

4. | Work piece moving. | 4.Clamp workpiece securely. See Material Clamping and Supporting page 4. Make sure |

|

| material is laying flat against the base. |

TROUBLE! CANNOT MOVE ARM |

| |

WHAT’S WRONG? | WHAT TO DO… | |

1. | 1.Check for damaged parts. Check for excessive chips in guard. Replace or repair as needed. | |

2. | Chain is engaged. | 2.Push down slightly on the arm, remove chain from pin. Raise arm. |

TROUBLE! MATERIAL MOVES DURING CUT |

| |

WHAT’S WRONG? | WHAT TO DO… | |

1. | Fence slipping or workpiece incorrectly placed or clamped. | 1.See Material Clamping and Supporting, page 4. |

2. | Vise too loose | 2.Tighten vise clamping. |

3. | Excessive cutting force. | 3.Reduce cutting force. |

English

11