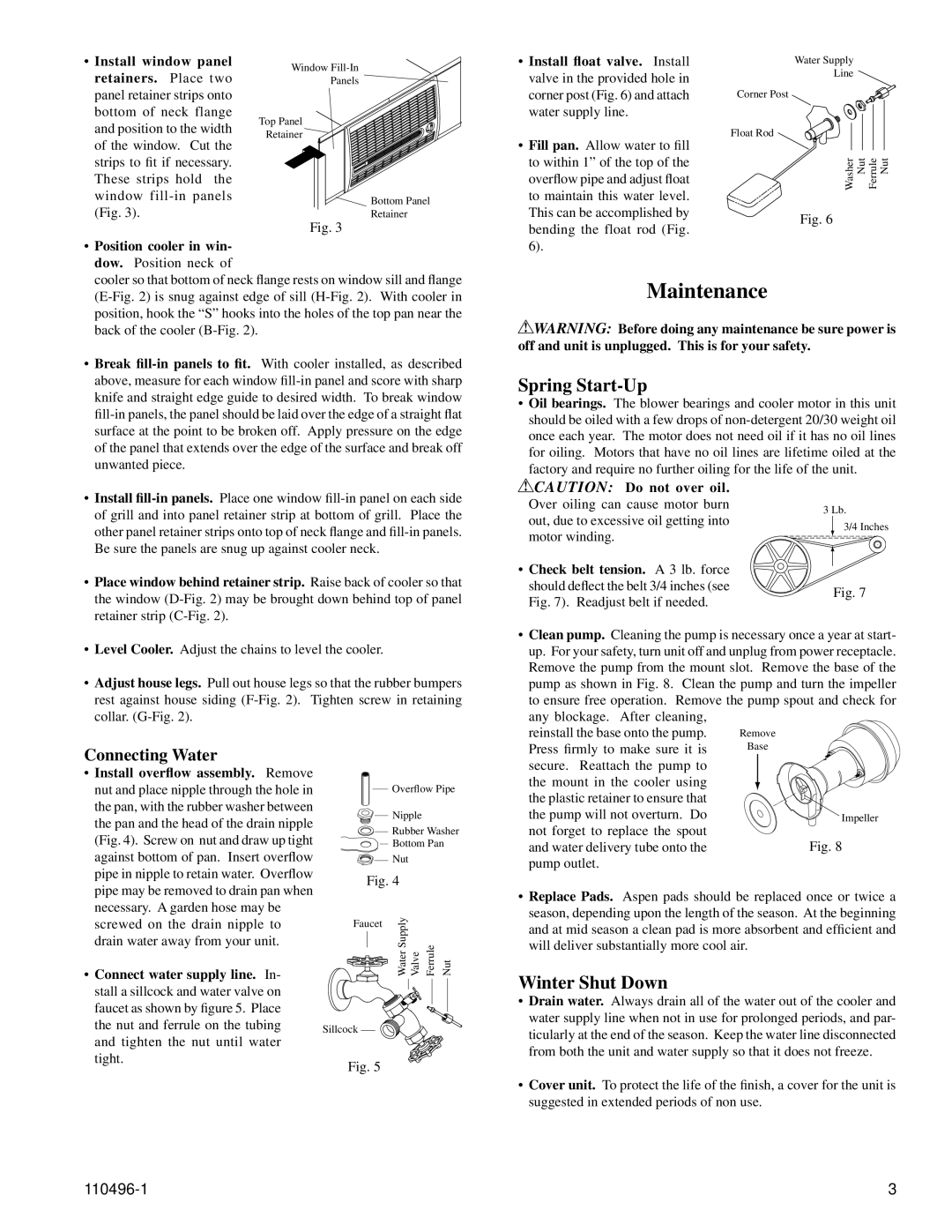

•Install window panel retainers. Place two panel retainer strips onto bottom of neck flange and position to the width of the window. Cut the strips to fit if necessary. These strips hold the window

Window

Panels

Top Panel

Retainer

Bottom Panel

Retainer

Fig. 3

• Install float valve. Install |

valve in the provided hole in |

corner post (Fig. 6) and attach |

water supply line. |

• Fill pan. Allow water to fill |

to within 1” of the top of the |

overflow pipe and adjust float |

to maintain this water level. |

This can be accomplished by |

bending the float rod (Fig. |

Water Supply

Line

Corner Post

Float Rod

Nut

Ferrule

Nut

Washer

Fig. 6

• Position cooler in win- |

dow. Position neck of |

cooler so that bottom of neck flange rests on window sill and flange |

|

position, hook the “S” hooks into the holes of the top pan near the |

back of the cooler |

• Break |

above, measure for each window |

knife and straight edge guide to desired width. To break window |

surface at the point to be broken off. Apply pressure on the edge |

of the panel that extends over the edge of the surface and break off |

unwanted piece. |

6). |

Maintenance

![]() WARNING: Before doing any maintenance be sure power is off and unit is unplugged. This is for your safety.

WARNING: Before doing any maintenance be sure power is off and unit is unplugged. This is for your safety.

Spring Start-Up

•Oil bearings. The blower bearings and cooler motor in this unit should be oiled with a few drops of

• Install |

of grill and into panel retainer strip at bottom of grill. Place the |

other panel retainer strips onto top of neck flange and |

Be sure the panels are snug up against cooler neck. |

• Place window behind retainer strip. Raise back of cooler so that |

the window |

retainer strip |

![]() CAUTION: Do not over oil. Over oiling can cause motor burn out, due to excessive oil getting into motor winding.

CAUTION: Do not over oil. Over oiling can cause motor burn out, due to excessive oil getting into motor winding.

•Check belt tension. A 3 lb. force should deflect the belt 3/4 inches (see Fig. 7). Readjust belt if needed.

3 Lb.

3/4 Inches

Fig. 7

• | Level Cooler. Adjust the chains to level the cooler. |

• Adjust house legs. Pull out house legs so that the rubber bumpers | |

| rest against house siding |

| collar. |

•Clean pump. Cleaning the pump is necessary once a year at start- up. For your safety, turn unit off and unplug from power receptacle. Remove the pump from the mount slot. Remove the base of the pump as shown in Fig. 8. Clean the pump and turn the impeller to ensure free operation. Remove the pump spout and check for

any blockage. After cleaning, reinstall the base onto the pump.

Connecting Water

•Install overflow assembly. Remove nut and place nipple through the hole in the pan, with the rubber washer between the pan and the head of the drain nipple (Fig. 4). Screw on nut and draw up tight against bottom of pan. Insert overflow pipe in nipple to retain water. Overflow pipe may be removed to drain pan when necessary. A garden hose may be screwed on the drain nipple to drain water away from your unit.

•Connect water supply line. In- stall a sillcock and water valve on faucet as shown by figure 5. Place the nut and ferrule on the tubing and tighten the nut until water tight.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]() Overflow Pipe

Overflow Pipe

Nipple

Rubber Washer

Bottom Pan

Nut

Fig. 4

Faucet Supply

WaterValveFerruleNut

Sillcock

Fig. 5

Press firmly to make sure it is secure. Reattach the pump to the mount in the cooler using the plastic retainer to ensure that

the pump will not overturn. DoImpeller not forget to replace the spout

and water delivery tube onto the pump outlet.

•Replace Pads. Aspen pads should be replaced once or twice a season, depending upon the length of the season. At the beginning and at mid season a clean pad is more absorbent and efficient and will deliver substantially more cool air.

Winter Shut Down

•Drain water. Always drain all of the water out of the cooler and water supply line when not in use for prolonged periods, and par- ticularly at the end of the season. Keep the water line disconnected from both the unit and water supply so that it does not freeze.

•Cover unit. To protect the life of the finish, a cover for the unit is suggested in extended periods of non use.

| 3 |