•Install float and attach water line to float. The float may be installed in either the corner post or bracket (see Fig. 9). If you have model 3000DD/N31D then the float should be mounted to the bracket. Refer to figure 10 for installation instruc- tions. Insert the float (1) thru the hole in the corner post or bracket. Install the washer (2) and nut (3). Tighten to keep the float from turning. Place the nut (5) and ferrule (4) on the water supply line. Connect to float fitting and tighten until water tight.

•Fill pan. Allow water to fill to within 1” of top of pan and adjust

float to maintain this water level. This can be accomplished by bend- ing the float rod.

• Level water troughs. Operate |

pump until pads are saturated. |

Check each trough to see if water |

SupplyWater | Valve Ferrule Nut |

Faucet |

|

Sillcock

Fig. 8

Corner

PostBracket

Float

Fig. 9

safety. Adjust pulley to a larger diameter and readjust belt tension, plug motor in, install pad frame, and retest amperage draw. Repeat this process until correct amperage draw is attained. Increasing motor pulley diameter increases amperage draw. Decreasing motor pulley diameter decreases amperage draw (see Fig. 12).

![]() CAUTION: Do not operate cooler with larger amperage draw than specified on motor plate.

CAUTION: Do not operate cooler with larger amperage draw than specified on motor plate.

NOTE: No attempt should be made to completely install this unit without the aid of an electrician or someone familiar with testing amperage draw. Failure to comply with these instructions may void your warranty.

Maintenance

![]() WARNING: Before doing any maintenance be sure power is off. At the time you remove a pad frame be sure to unplug motor and pump. This is for your safety.

WARNING: Before doing any maintenance be sure power is off. At the time you remove a pad frame be sure to unplug motor and pump. This is for your safety.

Spring Start-Up

• Clean pump. Cleaning the pump is necessary once a year at |

is evenly dispersed in the trough. |

If they are not, loosen adjustment |

bolts and level trough. Retighten |

bolts. Check to see that all pads |

are saturated with water and that |

1

2

3

4

5

6

your safety, turn unit off and unplug motor and pump. Remove the pump |

from the mount slot. Remove the base of the pump (Fig. 13). Clean the |

pump and turn the impeller to ensure free operation. Remove the pump |

spout and check for any blockage. |

After cleaning, reinstall the base | Remove |

onto the pump. Press firmly to | Base |

there are no dry spots or openings |

in the pads. |

Fig. 10

make sure it is secure. Reattach |

the pump to the mount in the cooler |

using the plastic retainer to ensure |

Bleed-Off

Installation of the

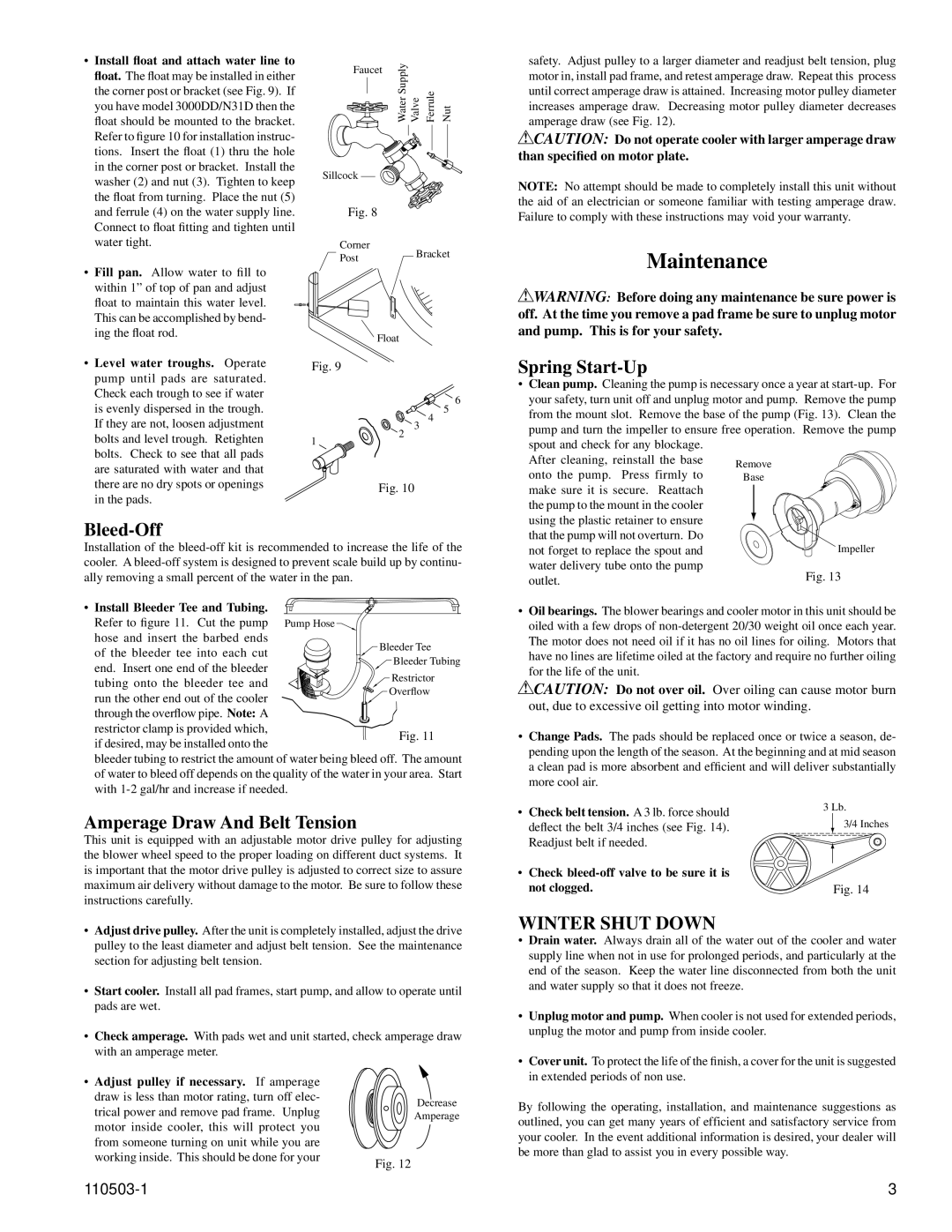

• Install Bleeder Tee and Tubing. Refer to figure 11. Cut the pump

hose and insert the barbed ends

of the bleeder tee into each cut

end. Insert one end of the bleeder tubing onto the bleeder tee and run the other end out of the cooler

through the overflow pipe. Note: A restrictor clamp is provided which, if desired, may be installed onto the

bleeder tubing to restrict the amount of water being bleed off. The amount of water to bleed off depends on the quality of the water in your area. Start with

Amperage Draw And Belt Tension

This unit is equipped with an adjustable motor drive pulley for adjusting the blower wheel speed to the proper loading on different duct systems. It is important that the motor drive pulley is adjusted to correct size to assure maximum air delivery without damage to the motor. Be sure to follow these instructions carefully.

•Adjust drive pulley. After the unit is completely installed, adjust the drive pulley to the least diameter and adjust belt tension. See the maintenance section for adjusting belt tension.

•Start cooler. Install all pad frames, start pump, and allow to operate until pads are wet.

•Check amperage. With pads wet and unit started, check amperage draw with an amperage meter.

• Adjust pulley if necessary. If amperage |

| |

draw is less than motor rating, turn off elec- | Decrease | |

trical power and remove pad frame. Unplug | ||

Amperage | ||

motor inside cooler, this will protect you |

| |

from someone turning on unit while you are |

| |

working inside. This should be done for your | Fig. 12 | |

|

that the pump will not overturn. Do | Impeller |

not forget to replace the spout and | |

water delivery tube onto the pump | Fig. 13 |

outlet. |

•Oil bearings. The blower bearings and cooler motor in this unit should be oiled with a few drops of

![]() CAUTION: Do not over oil. Over oiling can cause motor burn out, due to excessive oil getting into motor winding.

CAUTION: Do not over oil. Over oiling can cause motor burn out, due to excessive oil getting into motor winding.

•Change Pads. The pads should be replaced once or twice a season, de- pending upon the length of the season. At the beginning and at mid season a clean pad is more absorbent and efficient and will deliver substantially more cool air.

• Check belt tension. A 3 lb. force should | 3 Lb. | |

3/4 Inches | ||

deflect the belt 3/4 inches (see Fig. 14). | ||

Readjust belt if needed. |

|

•Check

not clogged. | Fig. 14 |

WINTER SHUT DOWN

•Drain water. Always drain all of the water out of the cooler and water supply line when not in use for prolonged periods, and particularly at the end of the season. Keep the water line disconnected from both the unit and water supply so that it does not freeze.

•Unplug motor and pump. When cooler is not used for extended periods, unplug the motor and pump from inside cooler.

•Cover unit. To protect the life of the finish, a cover for the unit is suggested in extended periods of non use.

By following the operating, installation, and maintenance suggestions as outlined, you can get many years of efficient and satisfactory service from your cooler. In the event additional information is desired, your dealer will be more than glad to assist you in every possible way.

| 3 |