2250C/2250S/2250M specifications

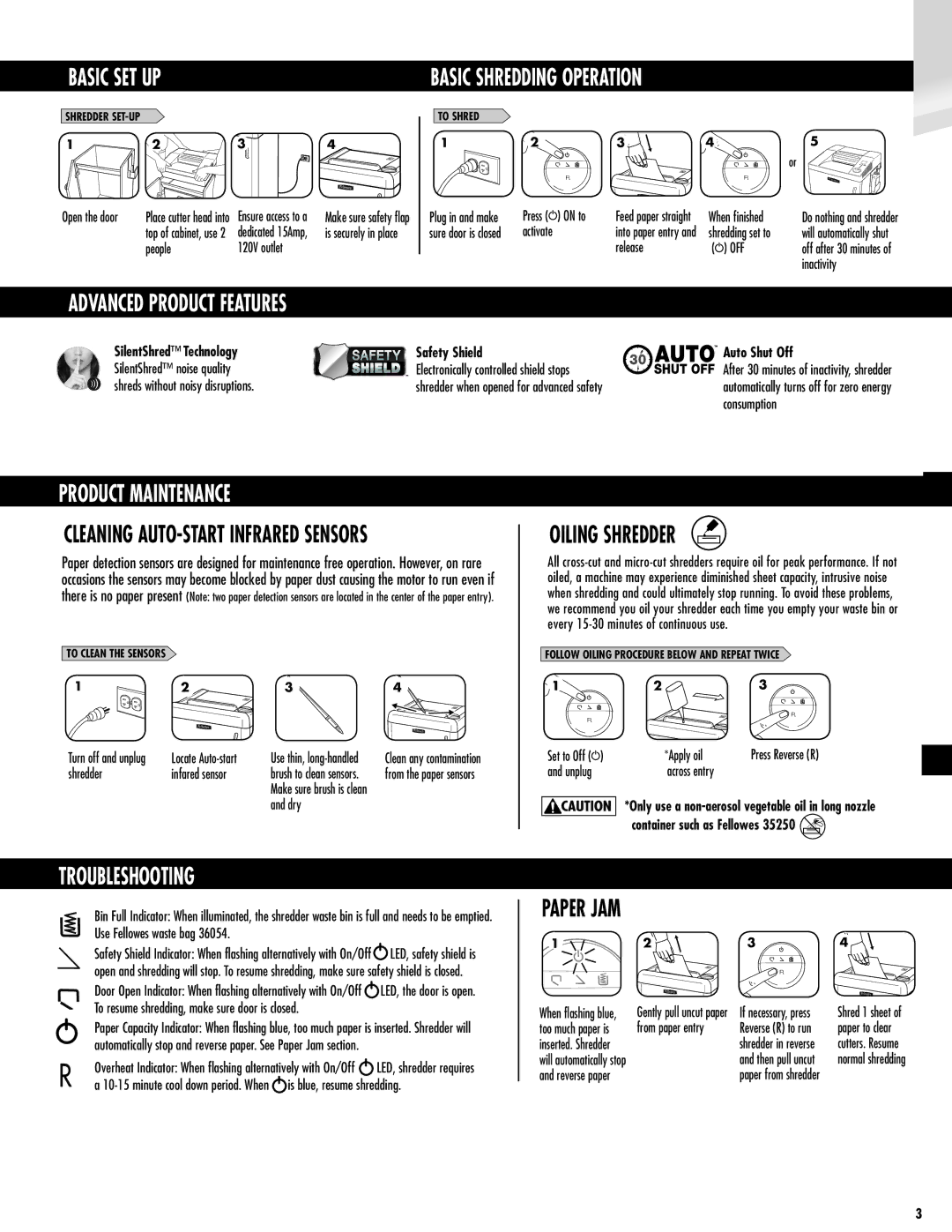

Fellowes, a leading brand in office products, offers a range of high-quality, efficient paper shredders, including the 2250C, 2250S, and 2250M models. These shredders are designed to provide advanced security, reliability, and ease of use, making them ideal for both home offices and professional environments.The Fellowes 2250C is a cross-cut shredder that effectively transforms documents into tiny, unreadable particles, ensuring confidential information remains secure. With a P-3 security level, the 2250C is perfect for shredding sensitive data such as financial records or personal information. It features a large capacity bin that can hold up to 10 gallons of shreds, reducing the frequency of emptying while allowing for prolonged use. Equipped with an easy-to-use control panel and a continuous duty motor, this model ensures smooth operation without the risk of overheating.

In contrast, the Fellowes 2250S offers a strip-cut shredding function, which provides a different level of security than its cross-cut counterpart. With the ability to shred up to 20 sheets of paper at once, the 2250S is efficient for handling larger volumes of paperwork. Its user-friendly design includes a forward/reverse button, making it easy to clear paper jams when they occur. The 2250S also boasts a sleek design that fits seamlessly into any office setting, while the 9-gallon waste bucket reduces maintenance time.

The Fellowes 2250M, on the other hand, represents the micro-cut shredding technology. This model delivers a higher level of security with a P-5 rating, shredding documents into extremely small particles that ensure sensitive information is virtually impossible to reconstruct. Ideal for organizations that require top-tier data protection, the 2250M manages to shred up to 12 sheets per pass, balancing both efficiency and security. Its smart sensing technology automatically detects paper and appropriately adjusts operations to optimize the shredding process.

Common features across these models include SilentShred technology, which minimizes noise during operation, making them suitable for shared office spaces. Each shredder also comes with safety features such as a safety lock that prevents unauthorized use and a thermal overload protection system to prevent overheating.

In summary, the Fellowes 2250C, 2250S, and 2250M shredders cater to varying security needs and operational preferences. From reliable cross-cut capabilities to advanced micro-cut technology, Fellowes continues to deliver innovative solutions for data protection in a variety of settings.