Smooth

The smooth

Speed regulation:

3.1 |

The speed controller (3.1) provides infinitely variable setting between 1350 and 3550 rpm of the speed of the saw blade. This enables you to optimize the cutting speed to suit the material.

Material | Speed |

| range |

Solid wood (hard, soft) | 6 |

Chipboards and hard fibre boards | |

Laminated wood, blockboards, ve- |

|

neered and coated boards | 6 |

Plastics, | |

paper and fabric |

|

Acrylic glass |

| Plaster and | |

| boards |

|

Al | Aluminium panels and profiles up | |

to 15 mm |

|

Constant speed:

The

Temperature cut-out

To prevent overheating, the safety electronics switches the machine off when it reaches a critical motor temperature.

Let the machine cool down for approx.

Current limiting

Current limiting prevents permissibly high current consumption under extreme overload. This can lead to a decrease in the motor speed. The motor immediately restarts after the load is removed.

Riving knife

![]() The TS 75 EQ is fitted with a riving knife (4.1) as standard. All saw work should, for safety reasons, only be carried out with the riving knife installed and correctly set!

The TS 75 EQ is fitted with a riving knife (4.1) as standard. All saw work should, for safety reasons, only be carried out with the riving knife installed and correctly set!

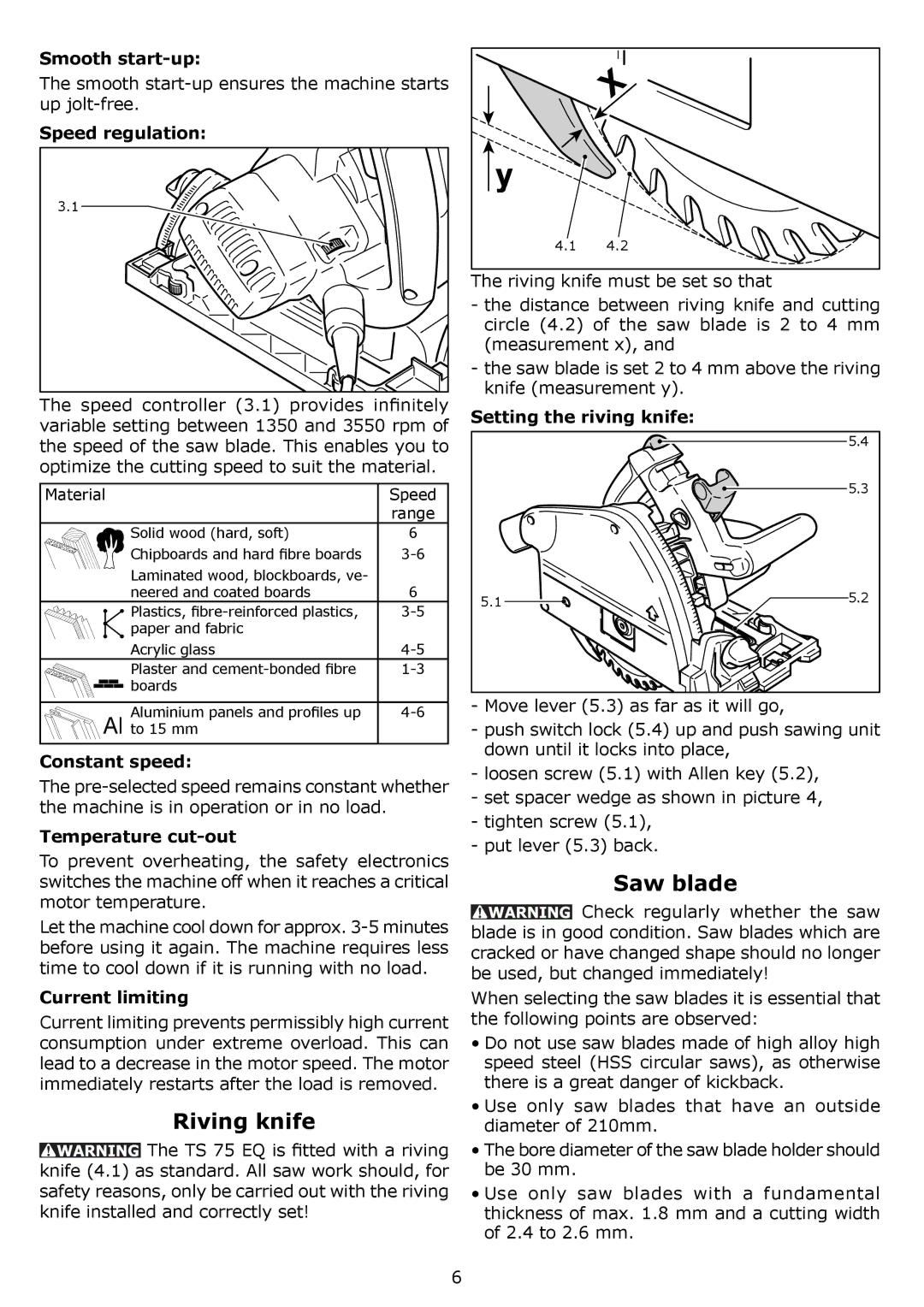

4.1 | 4.2 |

The riving knife must be set so that | |

-the distance between riving knife and cutting circle (4.2) of the saw blade is 2 to 4 mm (measurement x), and

-the saw blade is set 2 to 4 mm above the riving knife (measurement y).

Setting the riving knife:

| 5.4 |

| 5.3 |

5.1 | 5.2 |

-Move lever (5.3) as far as it will go,

-push switch lock (5.4) up and push sawing unit down until it locks into place,

-loosen screw (5.1) with Allen key (5.2),

-set spacer wedge as shown in picture 4,

-tighten screw (5.1),

-put lever (5.3) back.

Saw blade

![]() Check regularly whether the saw blade is in good condition. Saw blades which are cracked or have changed shape should no longer be used, but changed immediately!

Check regularly whether the saw blade is in good condition. Saw blades which are cracked or have changed shape should no longer be used, but changed immediately!

When selecting the saw blades it is essential that the following points are observed:

•Do not use saw blades made of high alloy high speed steel (HSS circular saws), as otherwise there is a great danger of kickback.

•Use only saw blades that have an outside diameter of 210mm.

•The bore diameter of the saw blade holder should be 30 mm.

•Use only saw blades with a fundamental thickness of max. 1.8 mm and a cutting width of 2.4 to 2.6 mm.

6