PAC571916, PI571916, ETS 150 EQ, ETS 153 EQ, PI571903 specifications

The Festool PAC571903, also known as the ETS 155 EQ, is a compact and versatile sander that embodies the company's commitment to high-quality engineering and user-focused design. This sander is particularly popular among professionals in woodworking and carpentry due to its efficient mechanics and robust performance.A key feature of the ETS 155 EQ is its exceptional dust extraction capabilities. With an integrated dust extraction port, users can connect the sander to a Festool dust extractor, ensuring a clean work environment and an extended tool lifespan. The design minimizes dust accumulation, making it ideal for indoor use where cleanliness is paramount.

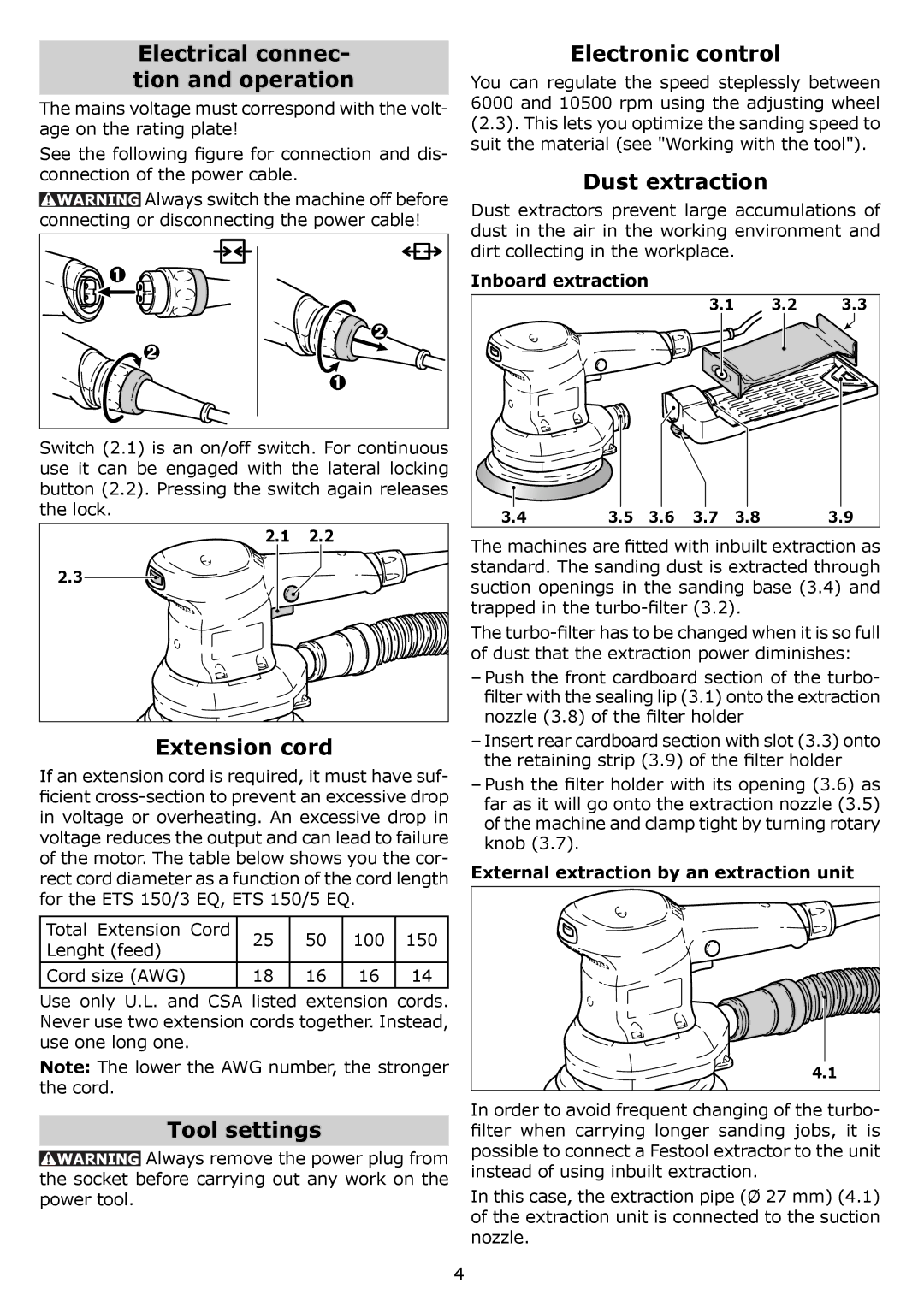

The ETS 155 EQ sander boasts a powerful and effective motor, delivering excellent results with its 5-inch sanding pad. Users can enjoy a high-quality finish due to the sander's ability to maintain consistent power output and speed. Additionally, the tool comes with a variable speed setting, allowing users to adjust the RPM to match the specific material and application needs.

Another notable technology found in the ETS 155 EQ is the vibration control system. The tool is engineered to minimize vibrations during operation, significantly reducing user fatigue for extended periods of sanding. This feature translates into a more comfortable user experience and better precision, especially in detailed tasks.

The innovative design of the sander includes an ergonomic grip that enhances control and maneuverability. Its lightweight construction further contributes to its usability, enabling users to handle it with ease in various orientations and spaces.

The PAC571903 also highlights modularity and versatility. It is compatible with a range of accessories and sanding pads, providing users with the ability to switch between different grits effortlessly, thereby tackling diverse projects. This adaptability makes it suitable for light sanding, finishing, and preparation work on various surfaces, from wood to painting.

In summary, the Festool PAC571903, ETS 155 EQ, and its associated component, PI571903, represent excellence in the power tool market. With its outstanding dust extraction, effective motor, vibration control technology, ergonomic design, and modular system, the ETS 155 EQ is a powerful ally for craftsmen seeking efficiency and precision in their work. Whether for professional use or serious DIY projects, this sander delivers quality results that meet high standards.