Aluminium processing

![]() The following precautions are to be taken when processing aluminium for safety reasons:

The following precautions are to be taken when processing aluminium for safety reasons:

-

-Connect the machine to a suitable dust extractor.

-Clean tool regularly of dust accumulations in the motor housing.

-Wear protective goggles.

Freehand routing

Freehand routing is the method normally used for lettering or shapes, and for routing edges using cutters with a guide pin or ring.

Routing with the parallel guide

|

| 9.1 |

|

| 9.2 |

9.8 | 9.3 | 9.3 |

|

| 9.4 |

| 9.5 | 9.5 |

|

| |

9.7 |

| 9.6 |

|

|

The parallel guide (9.8) (accessory) can be used for routing parallel to the edge of the workpiece.

-Clamp the two guide rods (9.6) to the parallel guide with the rotary knobs (9.3).

-Push the guide rods into the grooves (9.2) of the router table until the desired distance between the router and workpiece edge is reached. Clamp the guide rods tight with the rotary knobs (9.1).

This distance can be adjusted faster and more precisely with the fine precision adjustment (9.7) (accessory).

-Turn the adjusting screw (9.4) in the plastic part of the guide.

-Clamp the guide rods with the rotating knobs (9.5) in the precision adjustment.

-Loosen the rotating knobs (9.3) of the parallel guide, set the desired distance with the adjusting screw and retighten the rotating knobs.

Routing with the TV-

OF extension table

The extension table

edges. The extension table is fitted in the same way as the parallel guide.

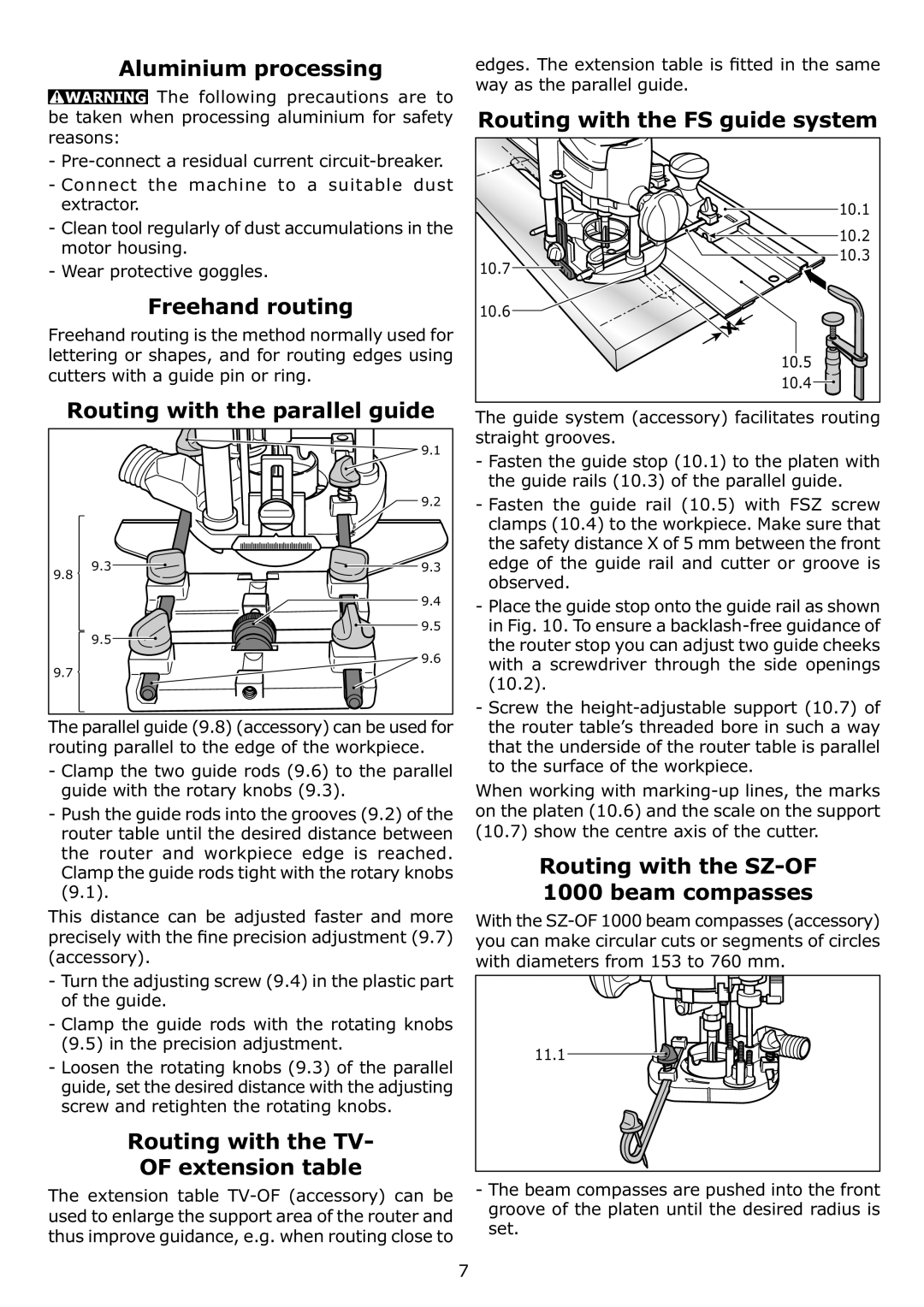

Routing with the FS guide system

10.1 |

10.2 |

10.3 |

10.7 |

10.6 |

10.5 |

10.4 |

The guide system (accessory) facilitates routing straight grooves.

-Fasten the guide stop (10.1) to the platen with the guide rails (10.3) of the parallel guide.

-Fasten the guide rail (10.5) with FSZ screw clamps (10.4) to the workpiece. Make sure that the safety distance X of 5 mm between the front edge of the guide rail and cutter or groove is observed.

-Place the guide stop onto the guide rail as shown in Fig. 10. To ensure a

-Screw the

When working with

Routing with the SZ-OF 1000 beam compasses

With the

11.1

-The beam compasses are pushed into the front groove of the platen until the desired radius is set.

7