-Lock the beam compasses with the rotating knob (11.1).

Practical hint: To prevent the tip of the compasses from making a hole in the workpiece, fix a thin board at the centre point by means of

Copy cutting

A copying ring or the copying device is used to exactly reproduce existing workpieces (both available as accessories).

a) Copying ring

![]() 12.112.2

12.112.2

12.3

Y

-Fasten the copying rings (12.2) to the platen instead of the cover ring (12.1) from below.

![]()

![]()

![]()

![]()

![]() When choosing the size of the copying ring (12.2) make sure that the cutter used (12.3) fits through the ring’s opening.

When choosing the size of the copying ring (12.2) make sure that the cutter used (12.3) fits through the ring’s opening.

The distance Y between the workpiece and template is calculated by:

Y

Y = 1/2 (Ø copying ring - Ø cutter) / 2

The copying ring can be centred exactly with the centring cone

b) Copying device

13.6 |

|

|

13.5 |

|

|

13.4 |

|

|

13.3 | 13.2 | 13.1 |

The angle arm

-Screw the angle arm at the desired height in the platen’s threaded bore (13.7) with the rotating knob (13.6).

-Fit a copying roller in the roller holder and bolt

this to the angle arm with the rotating knob

(13.4). Make sure that the copying roller and cutter have the same diameter!

-Turn the adjusting wheel (13.5) to adjust the distance between the copying roller and cutter axis.

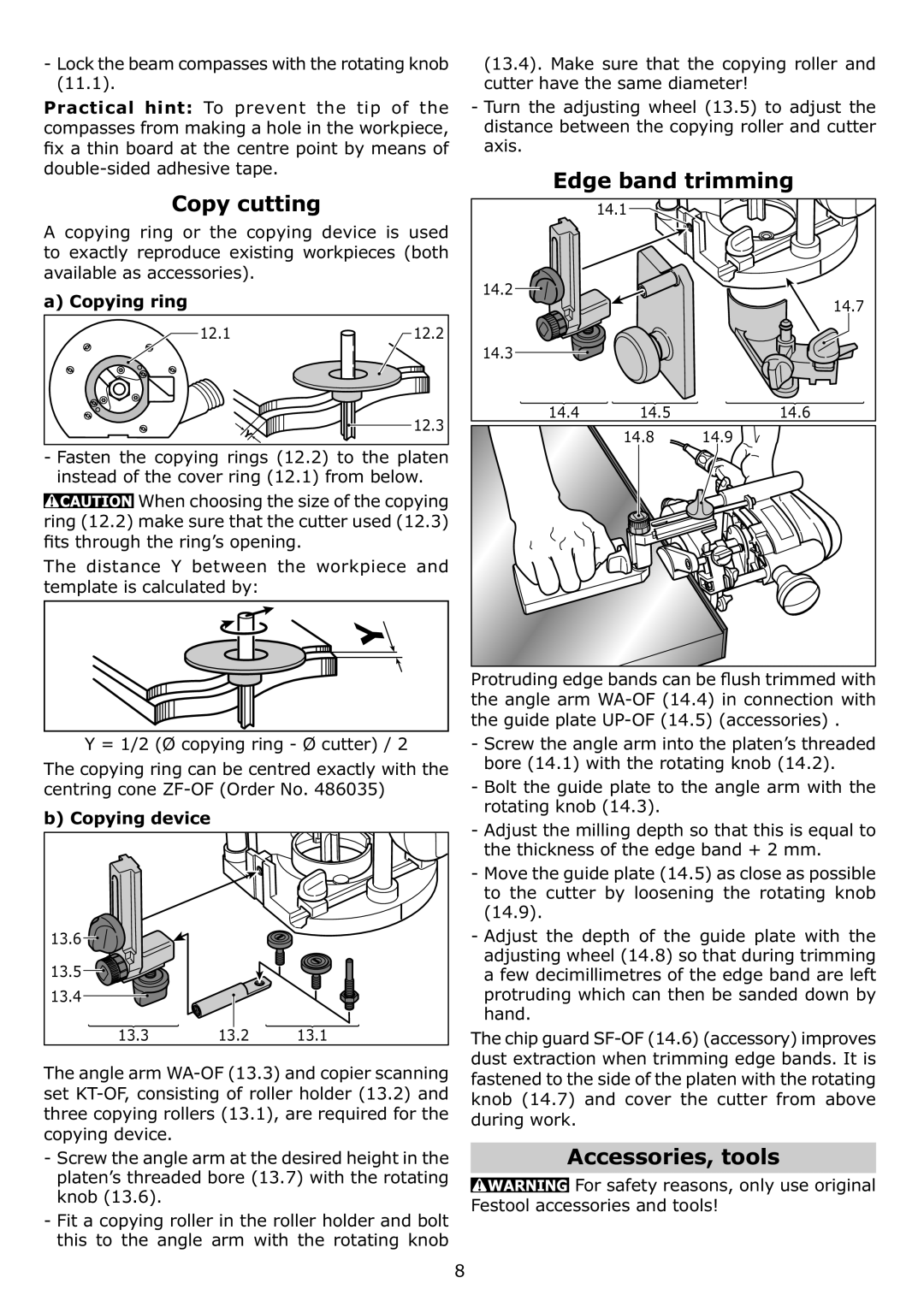

Edge band trimming

| 14.1 |

|

14.2 |

| 14.7 |

|

| |

14.3 |

|

|

14.4 | 14.5 | 14.6 |

| 14.8 | 14.9 |

Protruding edge bands can be flush trimmed with the angle arm

-Screw the angle arm into the platen’s threaded bore (14.1) with the rotating knob (14.2).

-Bolt the guide plate to the angle arm with the rotating knob (14.3).

-Adjust the milling depth so that this is equal to the thickness of the edge band + 2 mm.

-Move the guide plate (14.5) as close as possible to the cutter by loosening the rotating knob (14.9).

-Adjust the depth of the guide plate with the adjusting wheel (14.8) so that during trimming a few decimillimetres of the edge band are left protruding which can then be sanded down by hand.

The chip guard

Accessories, tools

![]() For safety reasons, only use original Festool accessories and tools!

For safety reasons, only use original Festool accessories and tools!

8