750MILLIVOLT PILOT GENERATOR APPLICATIONS

1.Disconnect the hot lead between the thermostat and the TH terminal on the gas valve. On older bleed tube style equipment split one lead of the E.C.O. (energy cut off) circuit.

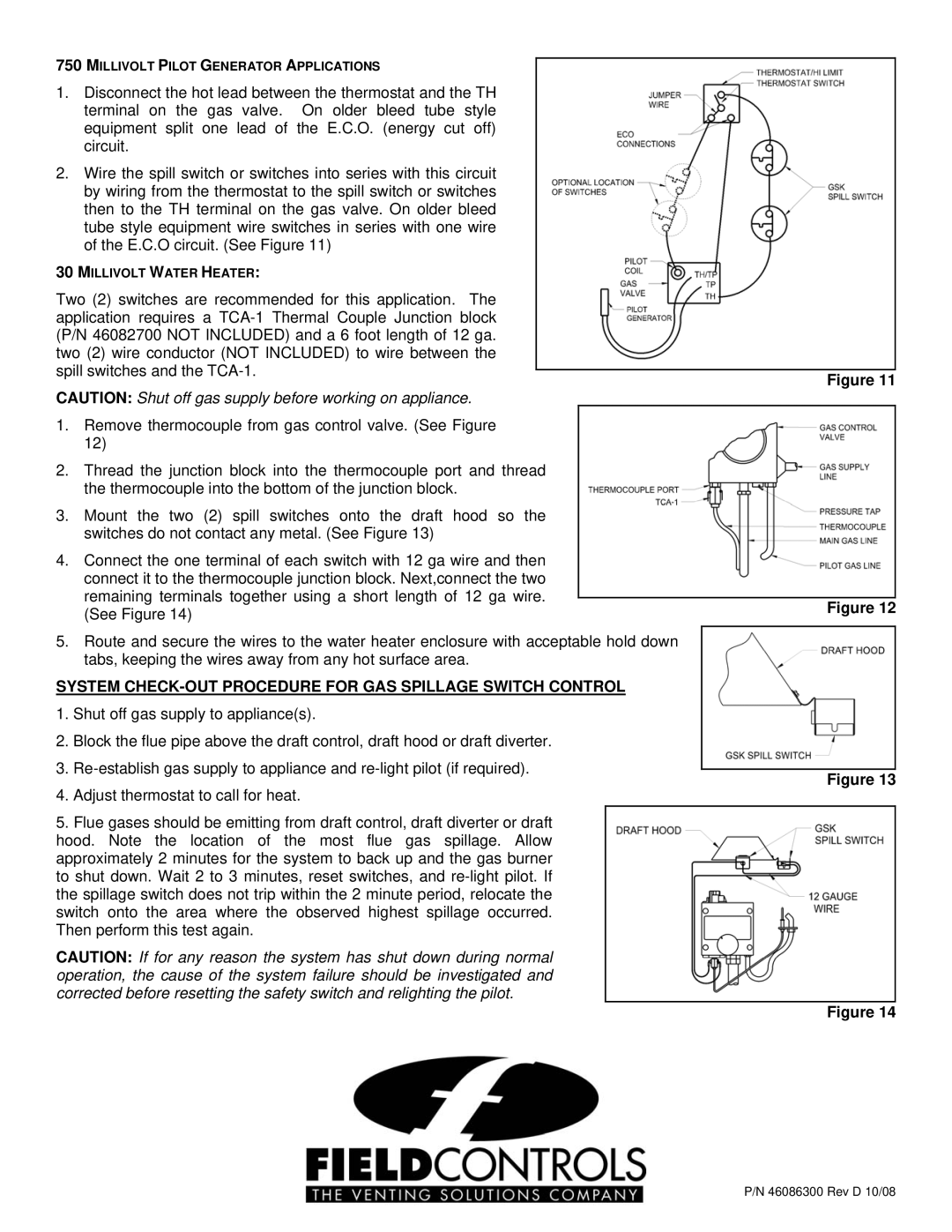

2.Wire the spill switch or switches into series with this circuit by wiring from the thermostat to the spill switch or switches then to the TH terminal on the gas valve. On older bleed tube style equipment wire switches in series with one wire of the E.C.O circuit. (See Figure 11)

30MILLIVOLT WATER HEATER:

Two (2) switches are recommended for this application. The application requires a

CAUTION: Shut off gas supply before working on appliance.

1.Remove thermocouple from gas control valve. (See Figure 12)

2.Thread the junction block into the thermocouple port and thread the thermocouple into the bottom of the junction block.

3.Mount the two (2) spill switches onto the draft hood so the switches do not contact any metal. (See Figure 13)

4.Connect the one terminal of each switch with 12 ga wire and then connect it to the thermocouple junction block. Next,connect the two remaining terminals together using a short length of 12 ga wire. (See Figure 14)

5.Route and secure the wires to the water heater enclosure with acceptable hold down tabs, keeping the wires away from any hot surface area.

SYSTEM CHECK-OUT PROCEDURE FOR GAS SPILLAGE SWITCH CONTROL

1.Shut off gas supply to appliance(s).

2.Block the flue pipe above the draft control, draft hood or draft diverter.

3.

4.Adjust thermostat to call for heat.

5.Flue gases should be emitting from draft control, draft diverter or draft hood. Note the location of the most flue gas spillage. Allow approximately 2 minutes for the system to back up and the gas burner to shut down. Wait 2 to 3 minutes, reset switches, and

CAUTION: If for any reason the system has shut down during normal operation, the cause of the system failure should be investigated and corrected before resetting the safety switch and relighting the pilot.

Page 4

Figure 11

Figure 12

Figure 13

Figure 14

P/N 46086300 Rev D 10/08